High-adhesive-force PVC sheet and preparation equipment thereof

A technology with high adhesion and production equipment, which is applied in the field of high adhesion PVC sheet and its production equipment, can solve the problems of non-compliance with the national strategy of green environmental protection, weakening of corona treatment effect, poor stability of treatment effect, etc., to achieve Improved transparency, enhanced firmness, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

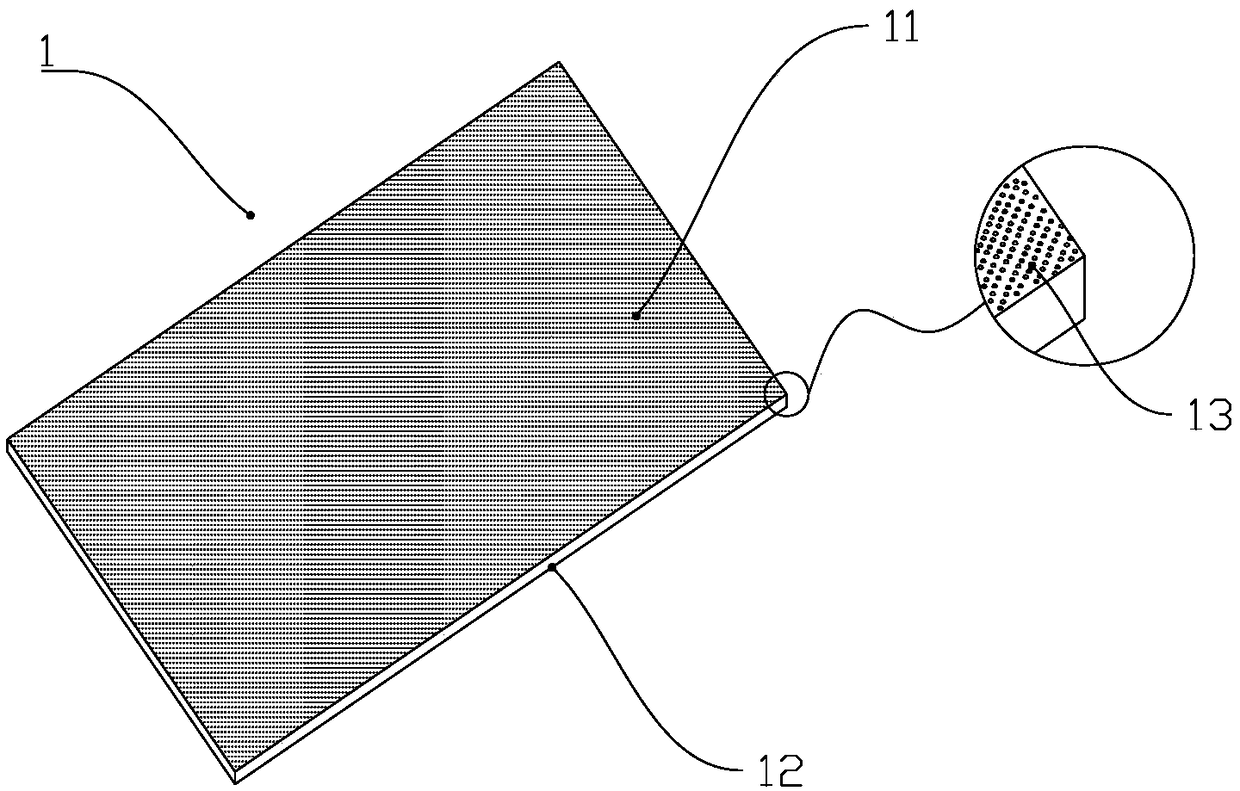

[0028] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-2 :

[0029] A PVC sheet with high adhesion, the upper surface of the sheet 1 is an adhesion surface 11, and the lower surface is a smooth surface 12, and a plurality of bumps 13 are evenly distributed on the adhesion surface 11, and the bumps 13 are The size is 1-100 μm.

[0030] The size of the above-mentioned bumps 13 is 1-100 μm, which means that the three dimensions of the bumps 13 are all 1-100 μm. The size between the bumps 13 is also 1-100 μm.

[0031] Preferably, the size of the bumps 13 is 1-10 μm.

[0032] The above-mentioned PVC sheet is a transparent material.

[0033] The above bumps 13 are semi-hemispherical.

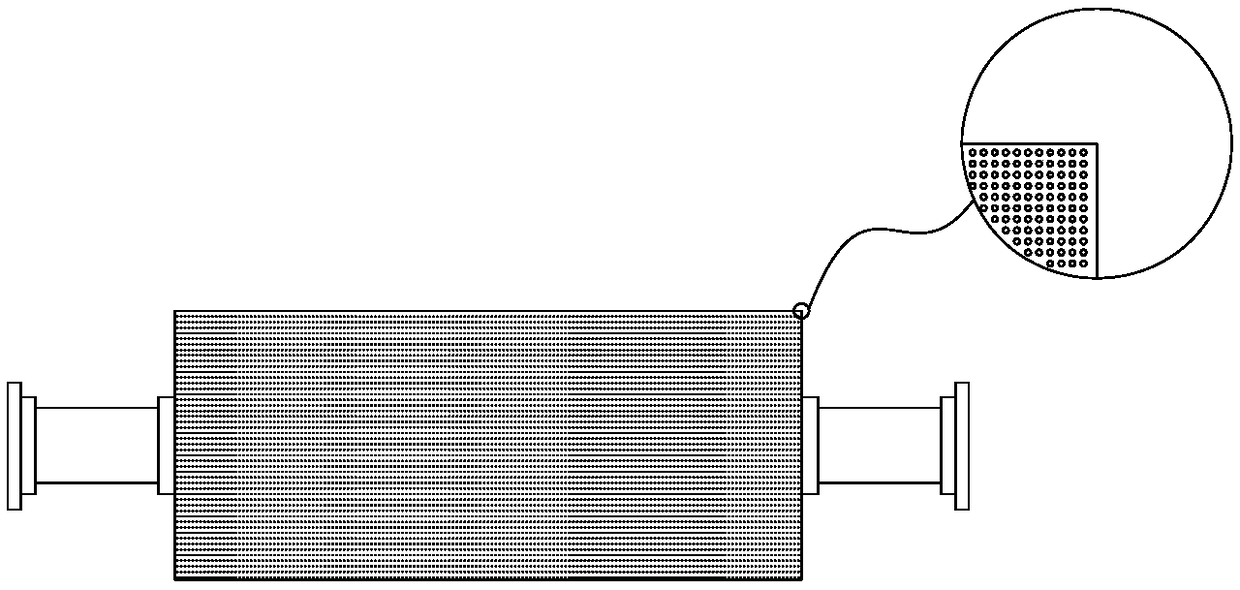

[0034] The present invention also provides a production equipment for PVC sheets with high adhesion, the production equipment is a pressing roller 2 or a sheet-discharging roller, and the surface of the pressi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com