LNG container filling distribution ship

A container and ship technology, applied in the field of LNG ships, can solve the problems of unable to meet the diversified needs of LNG, unable to achieve simultaneous transportation, short maintenance time, etc., to avoid the loss of tank maintenance time, increase flexibility, and save filling time. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

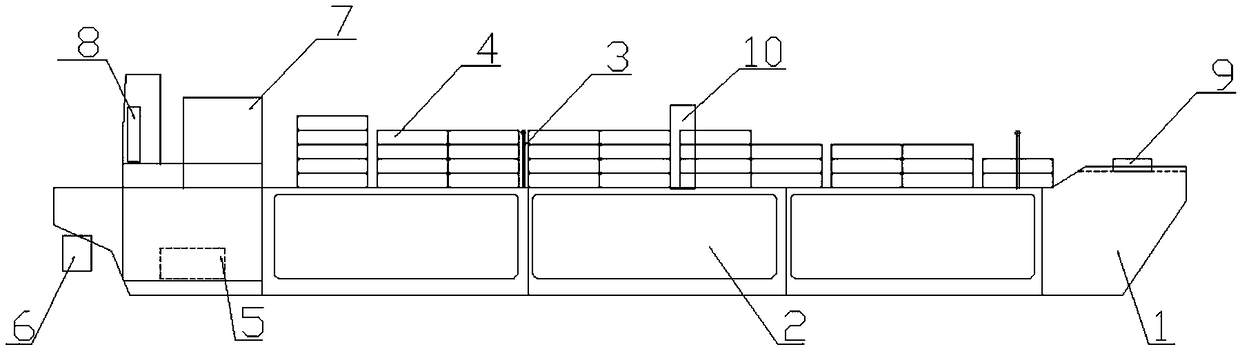

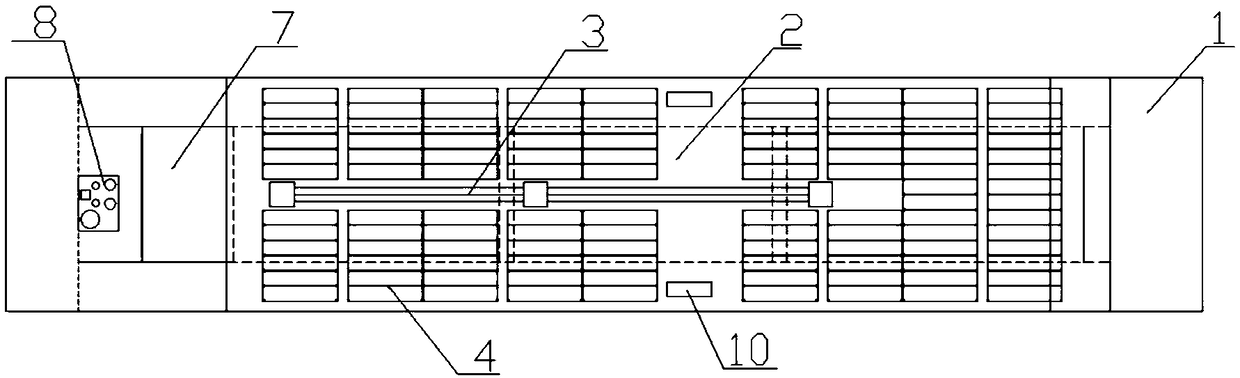

[0022] See figure 1 , figure 2 , figure 1 It is a schematic side view of the LNG container filling distribution ship of the present invention, figure 2 It is a top view schematic diagram of the LNG container filling distribution ship of the present invention. As can be seen from the figure, the LNG container tank distribution ship of the present invention includes a main hull 1, an LNG storage tank 2, a ship power system 5, a ship propulsion system 6, a superstructure 7, The marine turbine system 9 is characterized by LNG container 4, LNG container filling system 3, LNG combustion treatment system 8, and LNG filling system 10. 4 LNG containers, 2 LNG storage tanks below deck. The LNG filling system 10 is arranged on both sides of the middle part of the hull deck. The system is equipped with filling joints, control devices, flow meters, pressure gauges and other detection components. When berthing, the terminal equipment is connected with the filling joints. The device fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com