Environment-friendly light-proof double-layer waterproof packaging bag and preparation method thereof

A packaging bag and light-shielding technology, which is applied in the field of food packaging, can solve the problems of increased kraft paper price, easy damage on the surface, and non-environmental protection of paper-plastic composite bags, and achieve high light-shielding performance, strength performance, weather resistance, and cleanliness And waterproof, easy to recycle the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

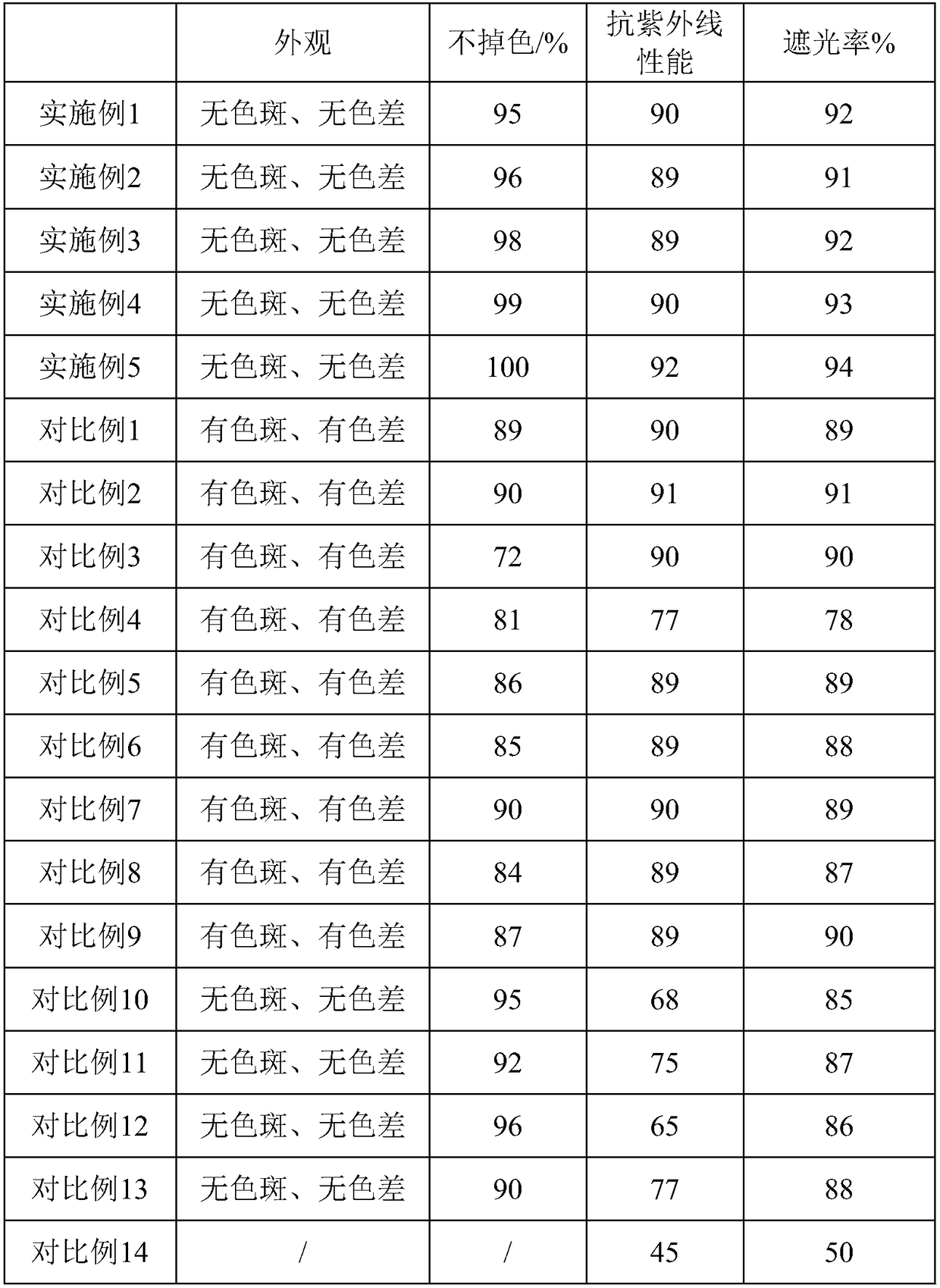

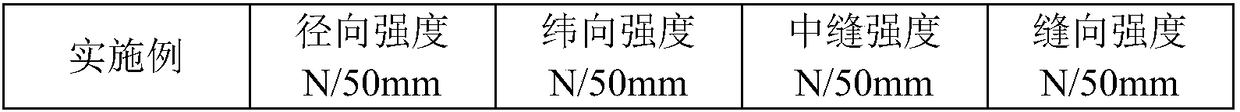

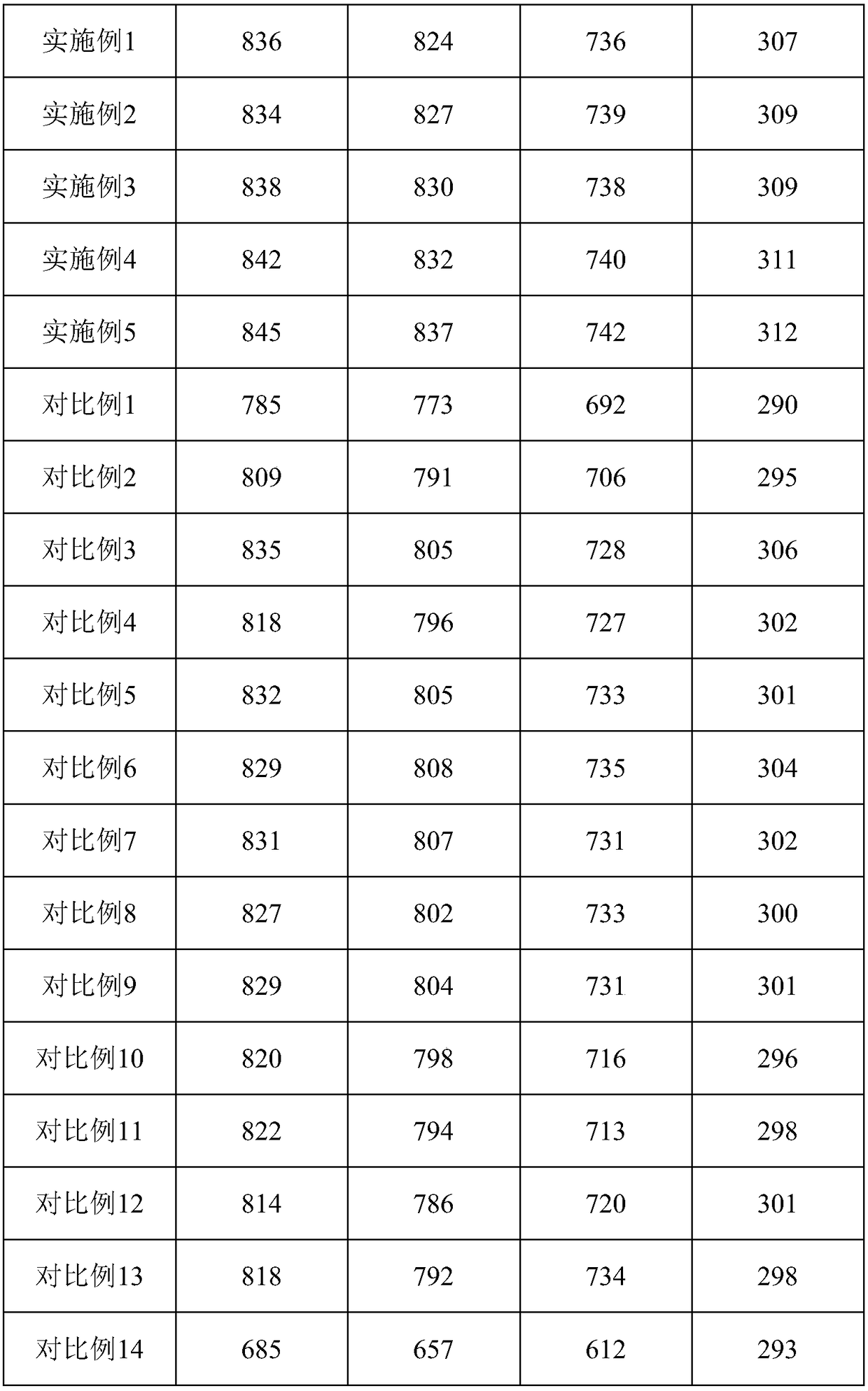

Examples

preparation example Construction

[0072] The second aspect of the present invention provides a method for preparing an environmentally friendly light-proof double-layer waterproof packaging bag, the steps comprising:

[0073] (1) Wire drawing: Stir the raw materials for the preparation of the plastic woven cloth layer according to a certain ratio, extrude into a film after heating, cut into strips after cooling in a water tank, and then stretch 5-6 times in a heating oven After being shaped and cooled, it is wound into a silk ingot to complete the production of silk;

[0074] (2) Weaving: put the coiled silk on the weaving machine, arrange it according to different specifications, weave it into a tube material crosswise in the warp and weft directions, cut it into pieces with a hot knife, and wind it up into a base cloth roll;

[0075] (3) Composite bag making: put the base material cloth roll on the compound machine, enter the surface layer compound device after preheating, stir the imitation kraft paper plas...

Embodiment 1

[0080] Embodiment 1 provides an environment-friendly light-proof double-layer waterproof packaging bag, the packaging bag includes a surface layer, a middle layer, and an inner layer; the surface layer is a plastic layer imitating kraft paper, the middle layer is a plastic woven cloth layer, and the inner layer is a pure plastic film layer.

[0081] The imitation kraft paper plastic layer 20g / m 2 , the plastic woven cloth layer 70g / m 2 , the pure plastic film 20g / m 2 .

[0082] In parts by weight, the raw materials for the preparation of the imitation kraft paper plastic layer include: 10 parts of polyethylene resin, 50 parts of polypropylene resin, 0.01 part of polyethylene wax, 0.01 part of antioxidant, 1 part of titanium dioxide, 0.1 part of tartrazine, Lisol Baohong bk 0.05 parts.

[0083] In parts by weight, the raw materials for preparing the plastic woven cloth layer include: 10 parts of polyethylene resin, 50 parts of polypropylene resin, 0.01 part of polyethylene wa...

Embodiment 2

[0104] Embodiment 2 provides an environment-friendly light-proof double-layer waterproof packaging bag, the packaging bag includes a surface layer, a middle layer, and an inner layer; the surface layer is a plastic layer imitating kraft paper, the middle layer is a plastic woven cloth layer, and the inner layer is a pure plastic film layer.

[0105] The imitation kraft paper plastic layer 25g / m 2 , the plastic woven cloth layer 80g / m 2 , the pure plastic film 25g / m 2 .

[0106] In parts by weight, the raw materials for the preparation of the imitation kraft paper plastic layer include: 50 parts of polyethylene resin, 100 parts of polypropylene resin, 5 parts of polyethylene wax, 0.3 parts of antioxidant, 10 parts of titanium dioxide, 1 part of tartrazine, 1 serving of Lisol Baohong bk.

[0107] In parts by weight, the raw materials for preparing the plastic woven cloth layer include: 50 parts of polyethylene resin, 98 parts of polypropylene resin, 5 parts of polyethylene w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com