Production method of ammonia-free natural concentrated latex

A production method and technology of concentrated rubber, applied in the field of rubber processing, can solve the problems affecting the quality of concentrated latex products, large equipment investment, difficult operation, etc., and achieve the effect of low cost, stable product quality and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

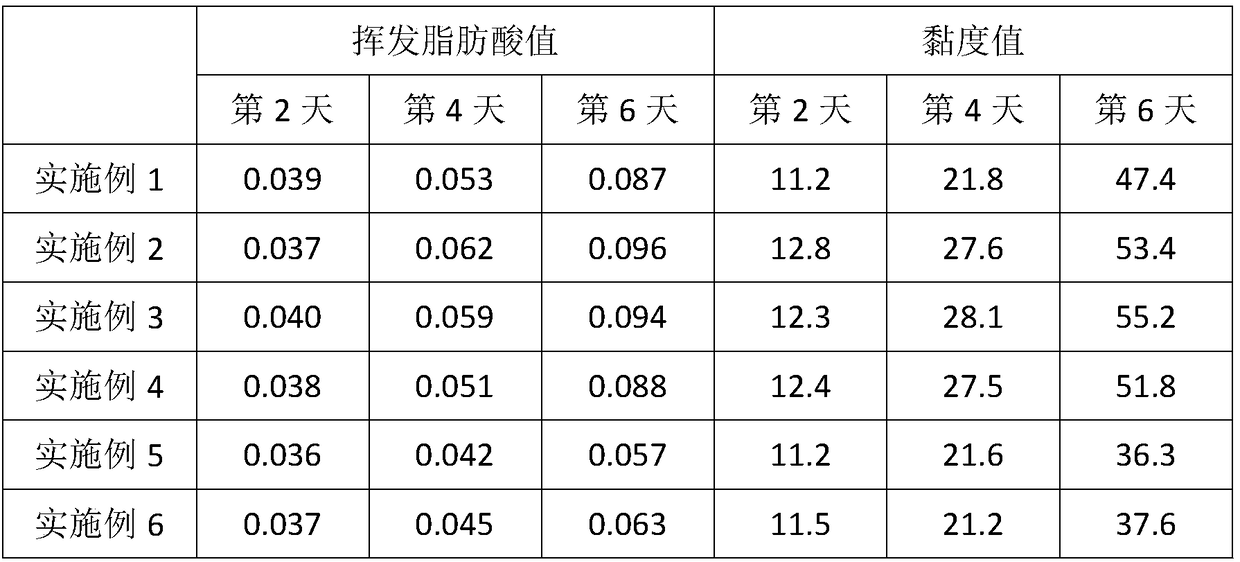

Examples

Embodiment 1

[0044] Embodiment 1 provides a kind of production method of ammonia-free natural concentrated latex, comprises the steps:

[0045] (1) Get 100kg natural latex, add the potassium laurate of natural latex 0.01wt% and carry out stabilizing treatment, then add the rubber vulcanization accelerator of natural fresh latex 0.03wt% and the zinc oxide of natural fresh latex 0.03wt%, stirring and mixing 10min , then adjust the pH value of the system to 10 with an alkaline stabilizer, and let it stand for 24 hours;

[0046] (2) the above-mentioned system is centrifugally concentrated and added potassium laurate of 0.05wt% of natural fresh latex, the described vulcanization accelerator of 0.03wt% of natural fresh latex and the described zinc oxide of 0.03wt% of natural fresh latex, stirring and mixing;

[0047] (3) Stability test is carried out to above-mentioned system, when its mechanical stability reaches 250 seconds, add 9g chemical stabilizer and preserve, can obtain the natural conce...

Embodiment 2

[0050] Embodiment 2 provides a kind of production method of ammonia-free natural concentrated latex, comprises the steps:

[0051] (1) Get 100kg natural fresh latex, add the potassium laurate of natural fresh latex 0.01wt% and carry out stabilizing treatment, add the rubber vulcanization accelerator of natural fresh latex 0.01wt% and the zinc oxide of natural fresh latex 0.01wt%, stirring and mixing 10min , then adjust the pH value of the system to 10 with an alkaline stabilizer, and let it stand for 24 hours;

[0052] (2) the above-mentioned system is centrifugally concentrated and added potassium laurate of 0.02wt% of natural fresh latex, the described vulcanization accelerator of 0.02wt% of natural fresh latex and the described zinc oxide of 0.02wt% of natural fresh latex, stirring and mixing;

[0053] (3) Stability test is carried out to above-mentioned system, when its mechanical stability reaches 300 seconds, add 9g chemical stabilizer and preserve, can obtain the natura...

Embodiment 3

[0056] Embodiment 3 provides a kind of production method of ammonia-free natural concentrated latex, comprises the steps:

[0057] (1) Get 100kg natural fresh latex, add the potassium laurate of natural fresh latex 0.01wt% and carry out stabilizing treatment, add the rubber vulcanization accelerator of natural fresh latex 0.15wt% and the zinc oxide of natural fresh latex 0.15wt%, stir and mix 10min , then adjust the pH value of the system to 10 with an alkaline stabilizer, and let it stand for 24 hours;

[0058] (2) the above-mentioned system is centrifugally concentrated and added potassium laurate of 0.07wt% of natural fresh latex, the described vulcanization accelerator of 0.05wt% of natural fresh latex and the described zinc oxide of 0.05wt% of natural fresh latex, stirring and mixing;

[0059] (3) Stability test is carried out to above-mentioned system, when its mechanical stability reaches 300 seconds, add 9g chemical stabilizer and preserve, can obtain the natural conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com