Rubber collection and preservation methods

A technology of rubber and preservative, applied in the rubber field, can solve the problem that rubber latex can not achieve good effect of preservation, achieve good color and odor, prevent acidity and odor, and reduce the effect of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

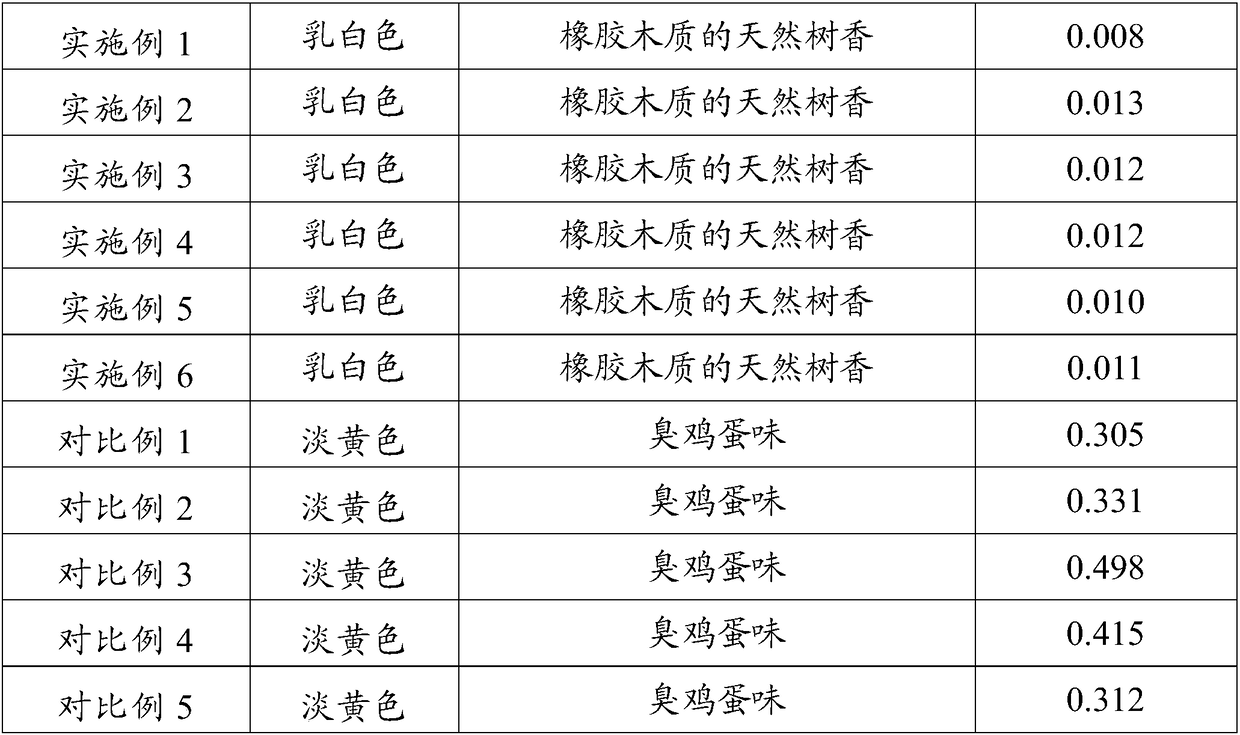

Examples

Embodiment 1

[0020] The method for collecting and preserving rubber comprises the following steps:

[0021] (1) rubber tree application regulator;

[0022] (2) before rubber latex is collected, stabilizer is placed in the collection vessel of rubber latex, makes latex slowly mix with stabilizer when flowing into collection vessel;

[0023] (3) After the collection of the rubber latex is completed, add a stabilizer to the latex, mix evenly, concentrate, and store.

[0024] The regulator includes the following components in parts by weight: 2 parts of ammonium molybdate, 0.5 part of ammonium chloride, 0.12 parts of borax, 1 part of glycerin, and 17 parts of ethephon stock solution with a content of 40%.

[0025] The stabilizer includes the following components in parts by weight: 10 parts of potassium ferrocyanide, 7 parts of sodium metabisulfite, 0.5 parts of sodium lauryl sulfate, 3 parts of chlorobutanol, and 5 parts of sodium carbonate.

[0026] The retaining agent includes the followi...

Embodiment 2

[0028] The method for rubber collection and property preservation comprises the following steps: the same as in Example 1.

[0029] The regulator includes the following components in parts by weight: 3 parts of ammonium molybdate, 1 part of ammonium chloride, 0.25 parts of borax, 3 parts of glycerin, and 20 parts of ethephon stock solution with a content of 60%.

[0030] The stabilizer includes the following components in parts by weight: 12 parts of potassium ferrocyanide, 5 parts of sodium metabisulfite, 1.5 parts of sodium lauryl sulfate, 1 part of chlorobutanol, and 8 parts of sodium carbonate.

[0031] The retaining agent includes the following components by weight: 14 parts of sodium sulfite, 2 parts of methyl p-hydroxybenzoate, 0.1 part of calcium hydroxide, 2.5 parts of sodium silicate pentahydrate, 2 parts of chitosan, 12 parts of citric acid , 7 parts of vitamin C, 15 parts of sodium benzoate, 1.2 parts of potassium sorbate, 3 parts of lemon yellow, 10 parts of lecit...

Embodiment 3

[0033] The method for rubber collection and property preservation comprises the following steps: the same as in Example 1.

[0034] The regulator includes the following components in parts by weight: 2.5 parts of ammonium molybdate, 0.6 parts of ammonium chloride, 0.20 parts of borax, 2 parts of glycerin, and 18 parts of ethephon stock solution with a content of 50%.

[0035] The stabilizer includes the following components in parts by weight: 11 parts of potassium ferrocyanide, 6 parts of sodium metabisulfite, 0.8 parts of sodium lauryl sulfate, 2 parts of chlorobutanol, and 6 parts of sodium carbonate.

[0036] The retaining agent includes the following components by weight: 11 parts of sodium sulfite, 3 parts of methyl p-hydroxybenzoate, 0.7 parts of calcium hydroxide, 1.6 parts of sodium silicate pentahydrate, 5 parts of chitosan, and 11 parts of citric acid , 6 parts of vitamin C, 12 parts of sodium benzoate, 1 part of potassium sorbate, 4 parts of lemon yellow, 9 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com