Preparation method of starch-based foaming buffer material

A cushioning material, starch-based technology, used in the field of foam materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

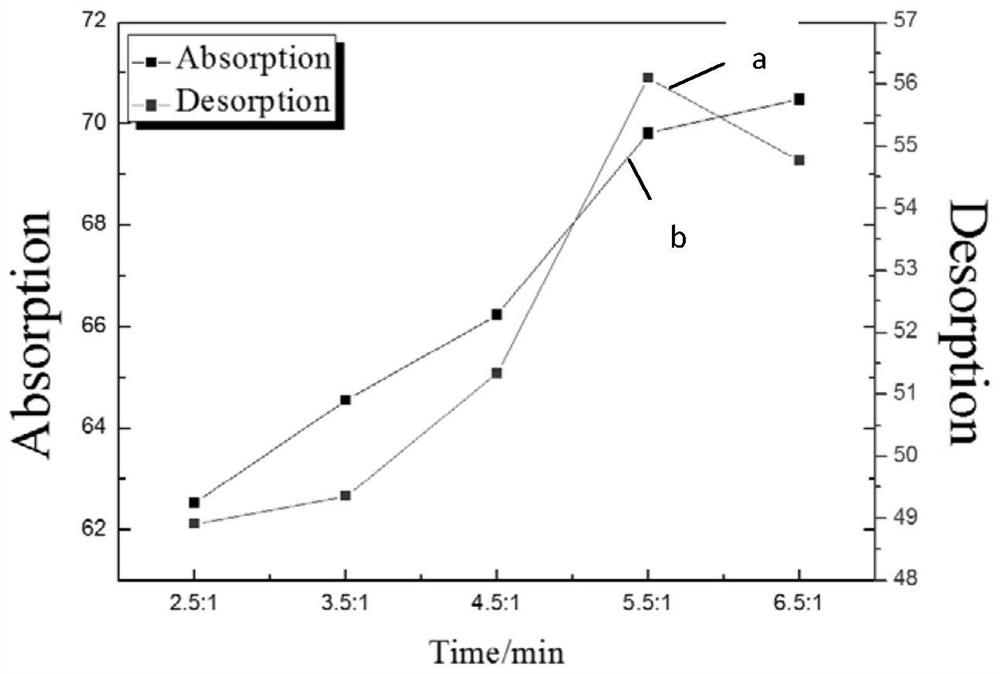

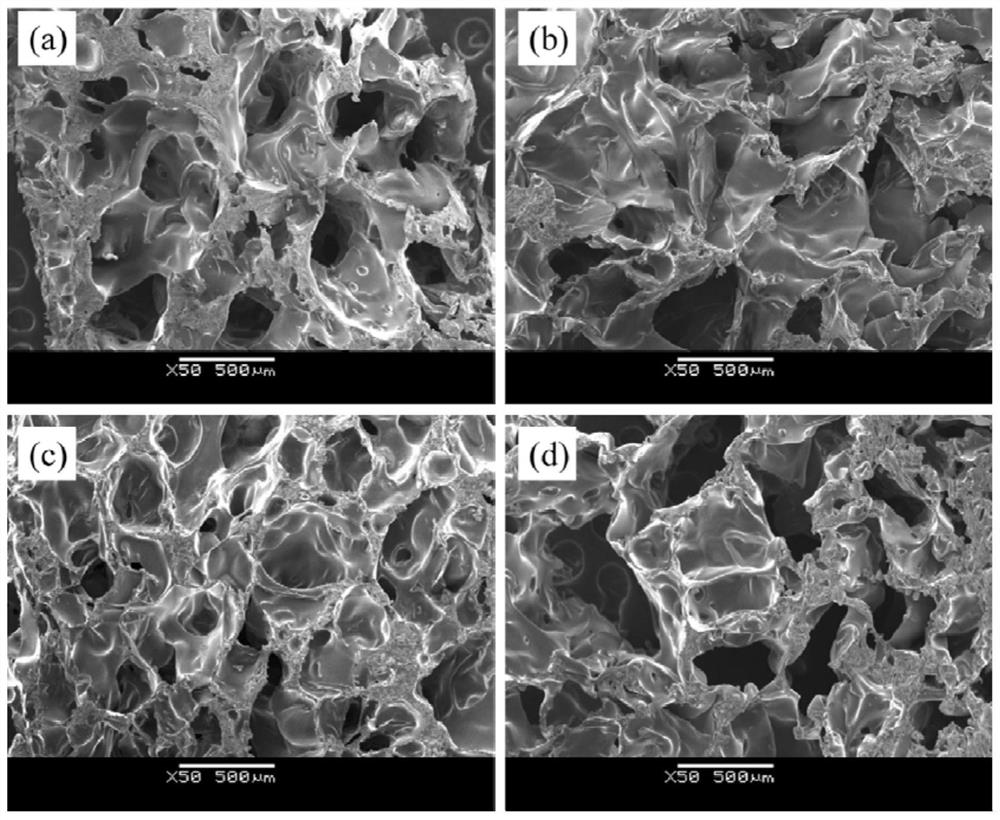

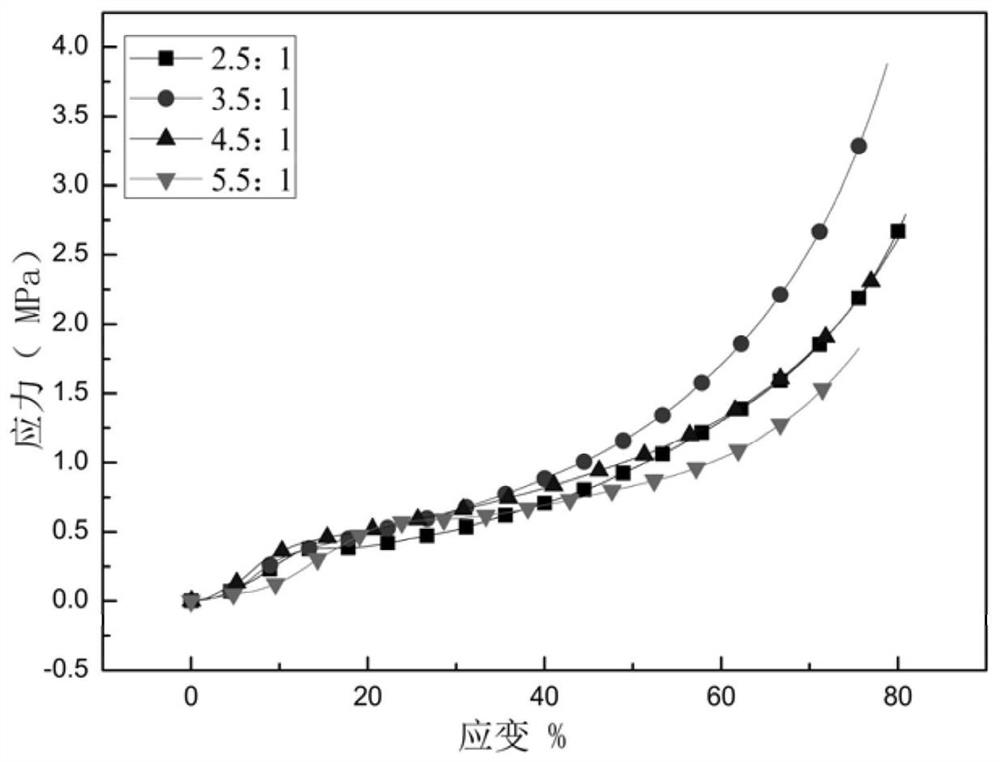

[0032] According to some embodiments, the preparation method of the above-mentioned starch-based foam buffer material specifically includes:

[0033] S1. Mix an inorganic strong base, acrylic acid and acrylamide to form a first composite humidity-conditioning material.

[0034] Specifically, the inorganic strong alkali solution is added dropwise to acrylic acid, then mixed with acrylic acid amine, and stirred until the acrylic amine is completely dissolved to obtain the first composite humidity control material, namely (acrylic acid + sodium acrylate)-acrylamide composite humidity control material . Wherein, the inorganic strong alkali solution is NaOH solution with a concentration of 28-40%, and the dropping process is carried out under cold water bath and electromagnetic stirring. The consumption of inorganic strong base, acrylic acid and acrylic acid amine is mixed according to the proportion in the above-mentioned raw material proportioning.

[0035] S2. Reacting the fir...

Embodiment 1

[0043] 1) Prepare the first composite humidity control material, namely acrylic acid-sodium acrylate-acrylamide solution:

[0044] Use 12g of water to prepare 6.8g of NaOH into a solution. Under a cold water bath and electromagnetic stirring, use a dropper to slowly add the prepared NaOH solution to 13.5g of acrylic acid (AA), and then follow (acrylic acid + sodium acrylate): Acrylamide (AM)=32.3g:9.6g mass ratio Weigh a certain amount of acrylamide and add it to the above-mentioned acrylic acid (sodium) solution, and keep stirring until AM is completely dissolved. Wherein, acrylic acid+sodium acrylate refers to a mixed solution obtained by dropping NaOH solution.

[0045] 2) Prepare the second composite humidity-conditioning material, that is, the starch-based composite humidity-conditioning material:

[0046] Weigh 6g of cornstarch, add it to the above mixed solution, stir and mix evenly, and gelatinize for 40min in a water bath with a temperature of 68°C and a speed of 410...

Embodiment 2

[0050] 1) Prepare the first composite humidity control material, namely acrylic acid-sodium acrylate-acrylamide solution:

[0051] Use 9.2g of water to prepare 4.4g of NaOH into a solution. Under cold water bath and electromagnetic stirring, slowly drop the prepared NaOH solution into 11.6g of acrylic acid (AA) with a dropper. : Mass ratio of acrylamide (AM)=25.2g:4.8g Weigh quantitative acrylamide and add it into the above-mentioned acrylic acid (sodium) solution, and keep stirring until AM is completely dissolved. Wherein, acrylic acid+sodium acrylate refers to a mixed solution obtained by dropping NaOH solution.

[0052] 2) Prepare the second composite humidity-conditioning material, that is, the starch-based composite humidity-conditioning material:

[0053] Weigh 2.4g of cornstarch, add it to the above mixed solution, stir and mix evenly, gelatinize in a water bath with a temperature of 62°C and a speed of 490r / min for 26min; after taking it out to room temperature, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com