Recovery technology for organic glass

A plexiglass and process technology, applied in the field of plexiglass recycling process, can solve problems such as insufficient cracking of plexiglass, and achieve the effects of saving the time for replacing equipment, improving recovery efficiency, and improving cracking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

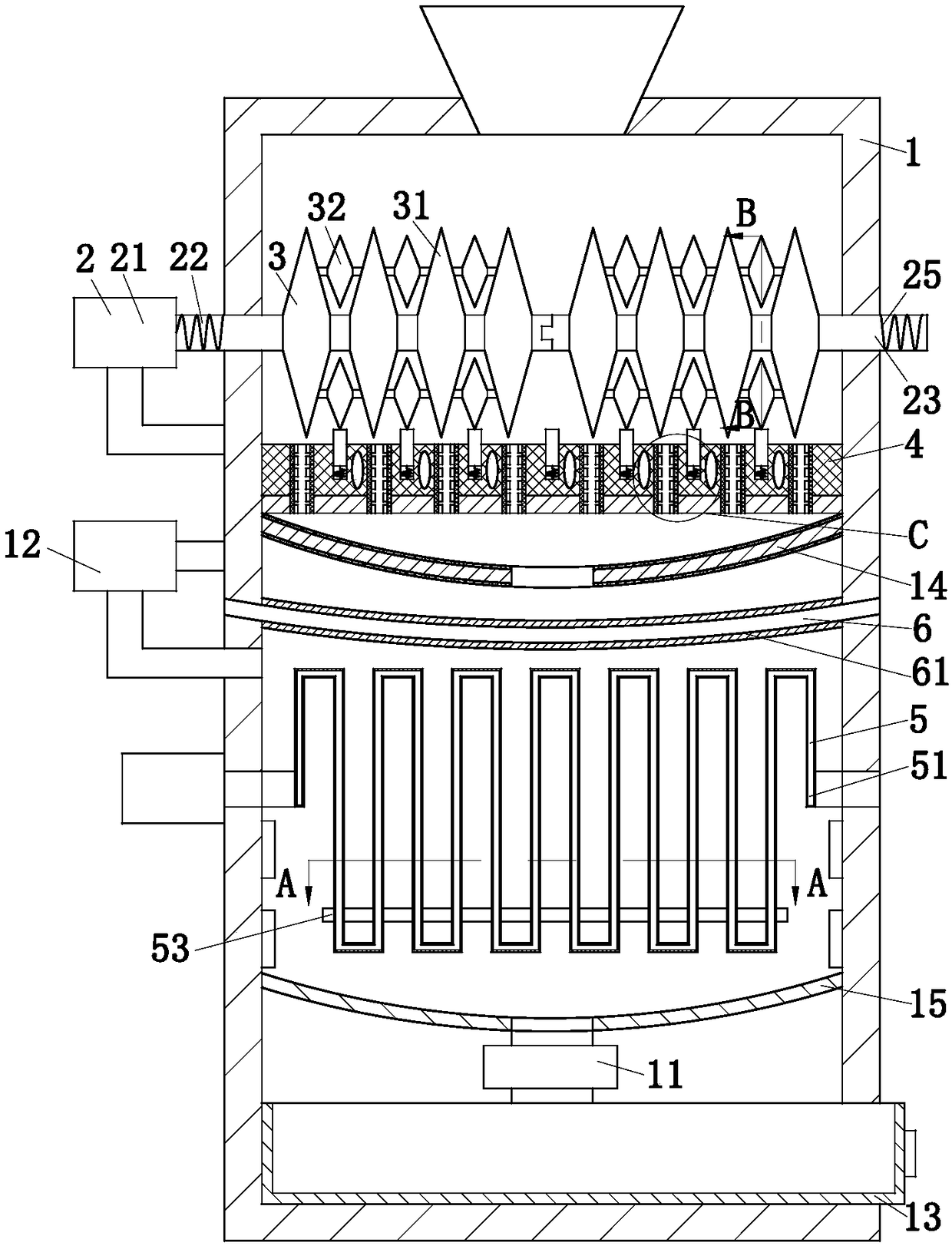

[0041] As an embodiment of the present invention, the elastic plate 41 is provided with a No. 1 slot 44 and a No. 1 cavity 45; the No. 1 cavity 45 is located between the No. 1 slot 44 and the No. 1 hole 43; No. groove 44 is provided with protruding teeth 46; said protruding teeth 46 are fixedly connected in No. 1 groove 44 by springs, and protruding teeth 46 cooperate with the cracking teeth on the No. 2 cracking wheel 32 to increase the breaking of organic glass. . The present invention is by arranging convex tooth 46, on the one hand, cooperates with the cracking tooth on No. two cracking wheel 32 by convex tooth 46, the cracking tooth on the second cracking wheel 32 squeezes convex tooth 46 in rotation, and convex tooth 46 is subjected to Extrusion moves away from No. 2 cracking wheel 32 sides, makes No. 1 cavity 45 produce gas, and this gas is used for assisting cracking unit 3 to carry out cracking to organic glass, thereby improved the cracking efficiency of organic glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com