A kind of thin-walled high CTI value flame-retardant polycarbonate blend and preparation method thereof

A technology of flame-retardant polycarbonate and polycarbonate, which is applied in the field of alloy materials, can solve the problems affecting the impact strength and heat resistance of PC resin, high CTI value, and low CTI value, and achieve improved tracking resistance, Improves heat resistance and toughness, improves the effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The invention discloses a thin-walled flame-retardant polycarbonate blend with high CTI value and a preparation method thereof. In terms of weight percentage, the polycarbonate composition comprises:

[0030] Polycarbonate 80-95%, silicone halogen-free flame retardant 0.05%-0.2%, phosphazene flame retardant 1-10%, anti-dripping agent 0.1-1%, other additives 3%-10%, each The sum of the percentages of the components is 100%,

[0031] Wherein the polycarbonate blend meets the CTIPLC 2 standard and has V0 performance at a thickness of 0.8 mm.

[0032] The polycarbonate is at least one of aromatic polycarbonate, aliphatic polycarbonate, aromatic-aliphatic polycarbonate, and branched polycarbonate.

[0033] The organosilicon halogen-free flame retardant is one or more mixtures of random silsesquioxane, ladder silsesquioxane, bridge silsesquioxane and cage silsesquioxane. The terminal group of the silicone halogen-free flame retardant is composed of one or two or more of ami...

Embodiment 2

[0042] Based on Example 1, this embodiment discloses a thin-walled high CTI value flame-retardant polycarbonate blend and a preparation method thereof. In terms of weight percentage, the polycarbonate composition includes:

[0043] Polycarbonate 80%, silicone halogen-free flame retardant 0.05%, phosphazene flame retardant 10%, anti-dripping agent 1%, other additives 8.95%, the sum of the percentages of each component is 100%.

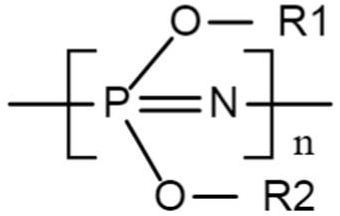

[0044] Among them, the polycarbonate is aliphatic polycarbonate, the silicone halogen-free flame retardant is random silsesquioxane, and the phosphazene flame retardant:

[0045]

[0046] , the repeating unit n is an integer of 3-25, the R1 group is the same as the R2 group, both represent unsubstituted phenyl groups, the anti-dripping agent is a polymer containing fluorine-containing vinyl structure, and other additives include: self-toughening agent 2%, heat stabilizer 3.55% and antioxidant 3.4%.

Embodiment 3

[0048] Based on Example 1, this embodiment discloses a thin-walled high CTI value flame-retardant polycarbonate blend and a preparation method thereof. In terms of weight percentage, the polycarbonate composition includes:

[0049] Polycarbonate 85%, silicone halogen-free flame retardant 0.1%, phosphazene flame retardant 8%, anti-dripping agent 0.5%, other additives 6.4%, the sum of the percentages of each component is 100%.

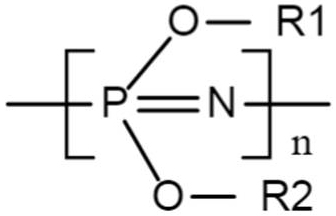

[0050] Among them, polycarbonate is aromatic polycarbonate, silicone halogen-free flame retardant is trapezoidal silsesquioxane, and phosphazene flame retardant is:

[0051]

[0052] , the repeating unit n is an integer of 3-25, the R1 group is the same as the R2 group, both represent a phenyl group substituted by an alkyl group containing at least one 1-6 carbon atom, and the anti-dripping agent is a polymer of fluorine-containing vinyl structure Other additives include: light stabilizer 3.2%, plasticizer 3.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com