Lubricant additive for free-piston-type linear power generator and preparation method of lubricant additive

A lubricating oil additive and linear generator technology, applied in additives, lubricating compositions, petroleum industry, etc., can solve the problems of low ash content in detergency performance, insufficient fuel combustion, etc., and achieve low ash content, good lubricating performance, and piston detergency performance Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

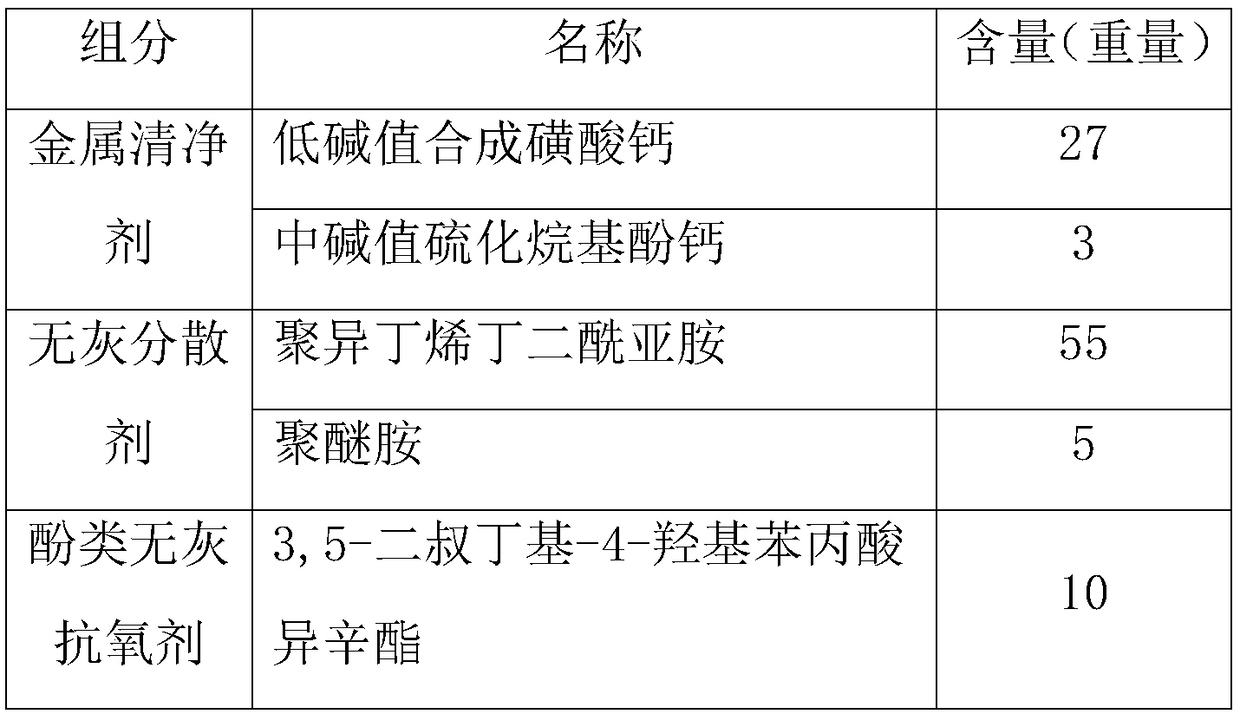

[0018] The free-piston linear generator lubricating oil additive provided by the present embodiment consists of the following components in parts by weight:

[0019]

[0020] The preparation method is to weigh the above-mentioned metal detergent, ashless dispersant and phenolic ashless antioxidant in proportion, then mix them at a temperature of 70° C., and fully stir them for 3 hours until they are evenly stirred.

Embodiment 2

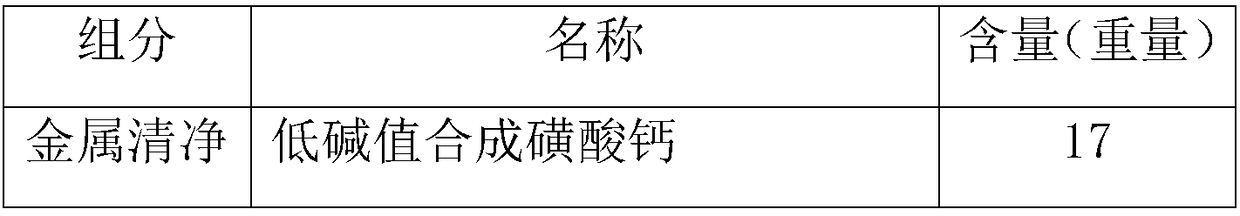

[0022] The free-piston linear generator lubricating oil additive provided by the present embodiment consists of the following components in parts by weight:

[0023]

[0024]

[0025] The preparation method is to weigh the above-mentioned metal detergent, ashless dispersant and phenolic ashless antioxidant in proportion, then mix them at a temperature of 80° C., and fully stir them for 2.5 hours until they are evenly stirred.

Embodiment 3

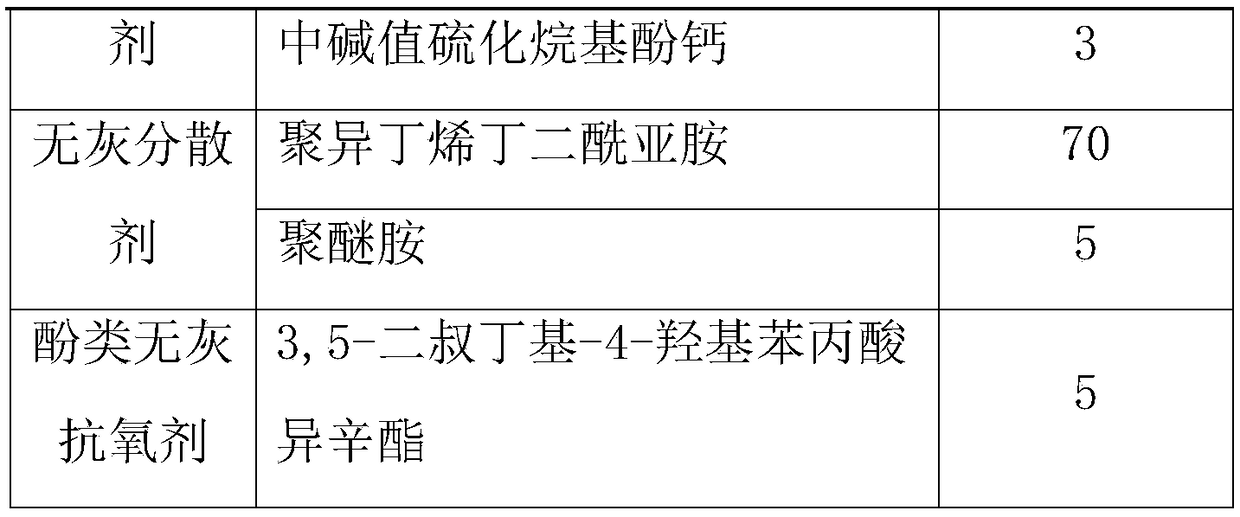

[0027] The free-piston linear generator lubricating oil additive provided by the present embodiment consists of the following components in parts by weight:

[0028]

[0029] The preparation method is to weigh the above-mentioned metal detergent, ashless dispersant and phenolic ashless antioxidant in proportion, then mix them at a temperature of 90° C., and fully stir them for 2 hours until they are evenly stirred.

[0030] The biodegradable ester synthetic oil is used as base oil, polyisobutylene and 5% by weight of the above-mentioned compounding agent are added to prepare lubricating oil. The national standard GB / T 2433 is used to test the sulfate ash content of oil products. The smaller the value, the less ash produced after combustion. The detergency and dispersibility of the oil was evaluated by the coke plate test. The test conditions were: plate temperature 330°C, oil temperature 100°C, stirring for 15s, stop for 45s, and the test period was 0.5h. The smaller the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com