Asphalt tank suitable for asphalt fissure cementation of road maintenance road surface and fissure cementation method

A technology of road maintenance and asphalt tank, which is applied in the field of road surface maintenance, can solve the problems of not having asphalt flattening, inconvenient crack cleaning, and not having the function of asphalt mixing, so as to achieve the effect of convenient mixing and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

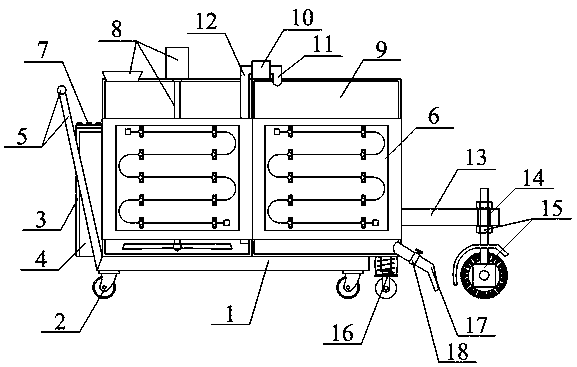

[0049] as attached figure 1 And attached Figure 4 shown

[0050] The invention provides an asphalt tank suitable for filling asphalt joints on road maintenance pavements, which includes a fixed bottom plate 1, a universal bottom wheel 2, an installation frame 3, a battery 4, a push rod 5, an asphalt heating shield structure 6, a power switch 7, and an asphalt tank. Spare storage mixing box structure 8, asphalt storage tank 9, suction pump 10, L-shaped discharge pipe 11, L-shaped suction pipe 12, horizontal fixing frame 13, longitudinal positioning hole 14, adjustable cleaning frame structure 15, auxiliary pressure Wheel structure 16, caulking pipe 17 and discharge valve 18, the universal bottom wheel 2 bolts are installed at the lower four corners of the fixed base plate 1; it is convenient and flexible to move the position of the asphalt tank during use; the battery 4 Placed on the inner side of the installation frame 3; the push rod 5 is welded on the left side of the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com