Arc friction type damper for reinforcing beam-column joint

A technology of beam-column joints and friction damping, which is applied in protective buildings/shelters, building components, and earthquake resistance, can solve problems such as plastic deformation of beam-column joints, achieve reduced plastic deformation, strong practicability, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

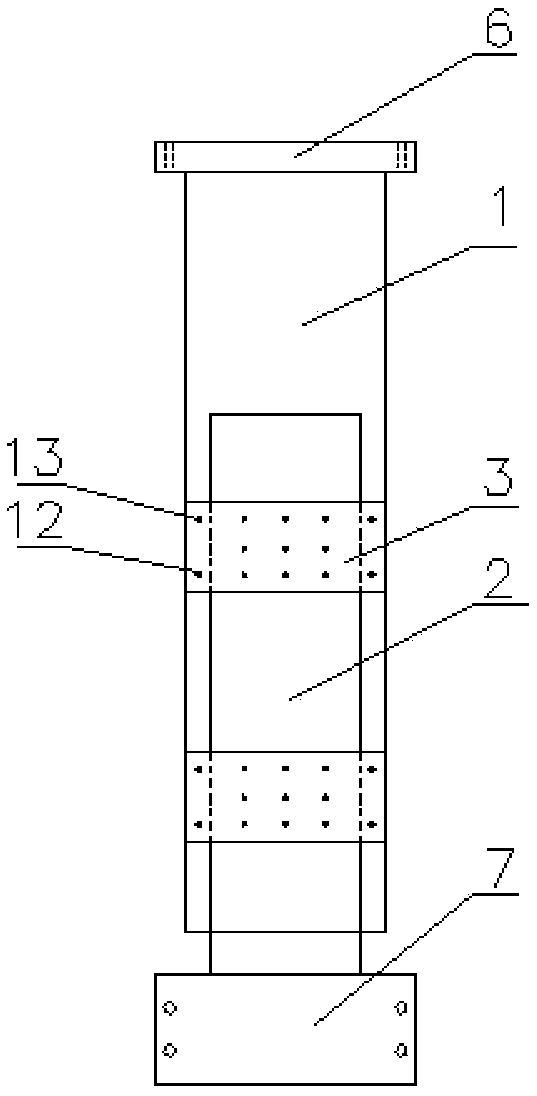

[0036] Such as Figure 5 As shown, a reinforcement column is provided in the middle of the reinforcement beam, and the reinforcement beam and the reinforcement column are perpendicular to each other. Around the connection position, a third connection device and a fourth connection device are provided on the reinforcement beam, and a fifth connection device is provided on the reinforcement column. The fifth connecting device, the third connecting device and the fourth connecting device have the same structure, and all include a connecting backing plate 10, and a plurality of connecting installation holes 2 are opened on the connecting backing board 10.

[0037] When using the third connecting device and the fourth connecting device, the first connecting plate 1 is placed under the reinforced beam, and the connecting backing plate 10 is placed above the reinforced beam and at the same position as the flange on the first connecting plate 1 On the contrary, after the first pull ro...

Embodiment 2

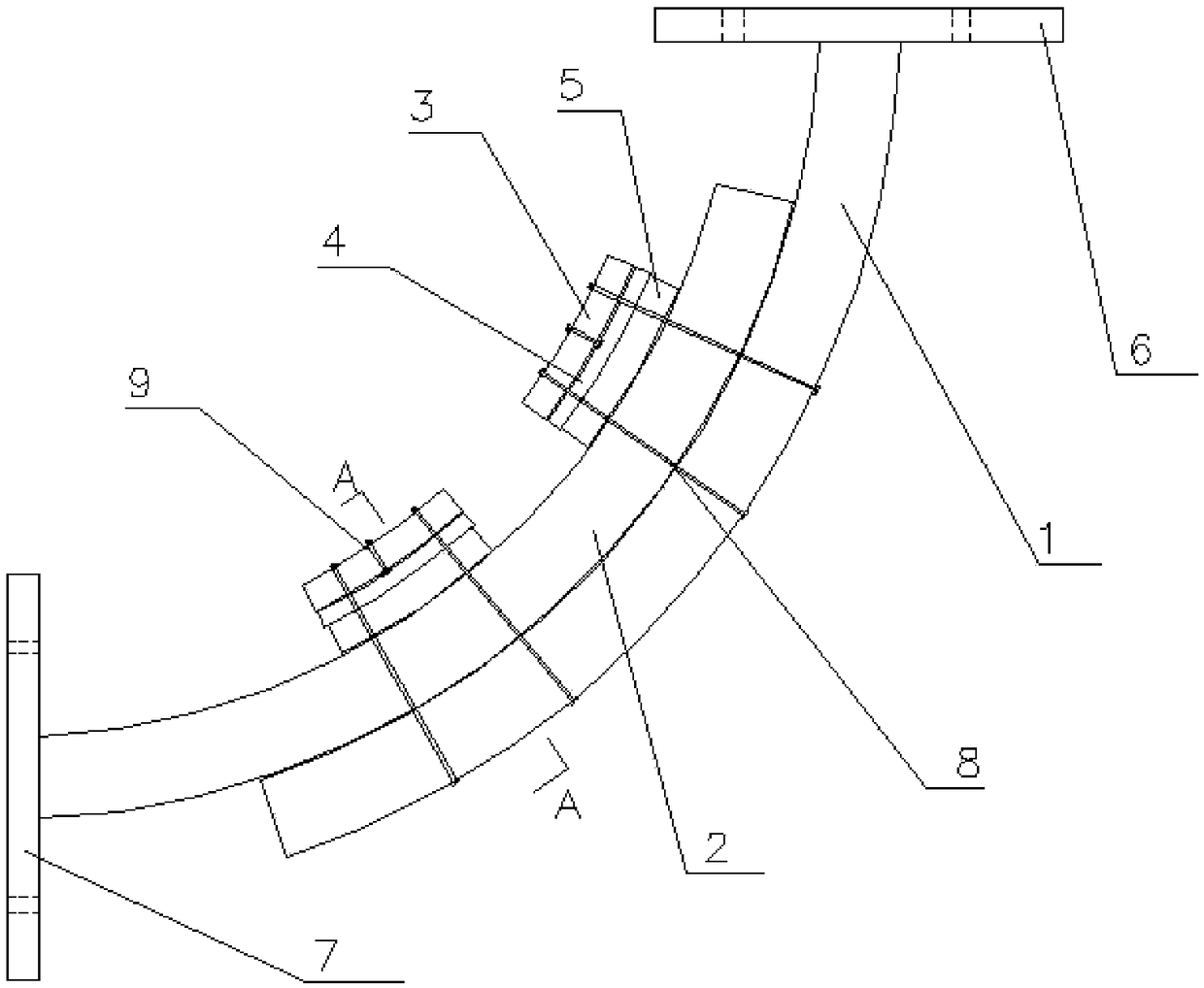

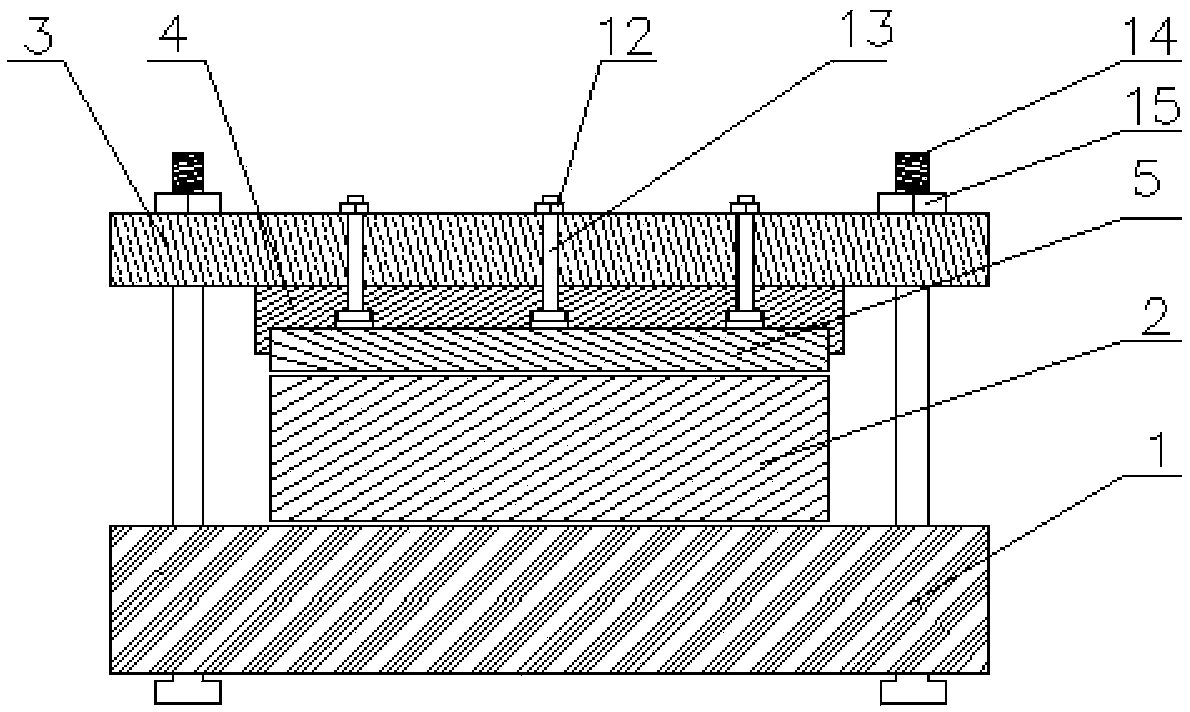

[0044] On the basis of the foregoing embodiments, as a further preferred solution, such as Image 6As shown, the arc-shaped friction damper is arranged on the reinforced beam and the reinforced column connected at right angles. The arc-shaped friction damper is composed of a friction damper, a first connecting plate 1 and a second connecting plate 2, and the second screw 14 connects the friction damping device, the first connecting plate 1 and the second connecting plate 2 .

[0045] The end of the reinforcement beam is provided with a reinforcement column connected thereto, and the reinforcement beam and the reinforcement column are vertical, and the two are connected in an L shape. Around the connection position, a sixth connection device is provided on the reinforcement beam, and a seventh connection device is provided on the reinforcement column. The connection device, the seventh connection device and the sixth connection device have the same structure, and all include a ...

Embodiment 3

[0049] As one of the preferred solutions, the arc-shaped friction damper of the invention can also be applied to any angle between beams and columns with an angle between 45° and 135°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com