Self-adaptive damping piston and damper

A damping piston, self-adaptive technology, applied in the field of mechanical spare parts, can solve problems such as the inability to adjust the damping value, and achieve the effect of wide industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

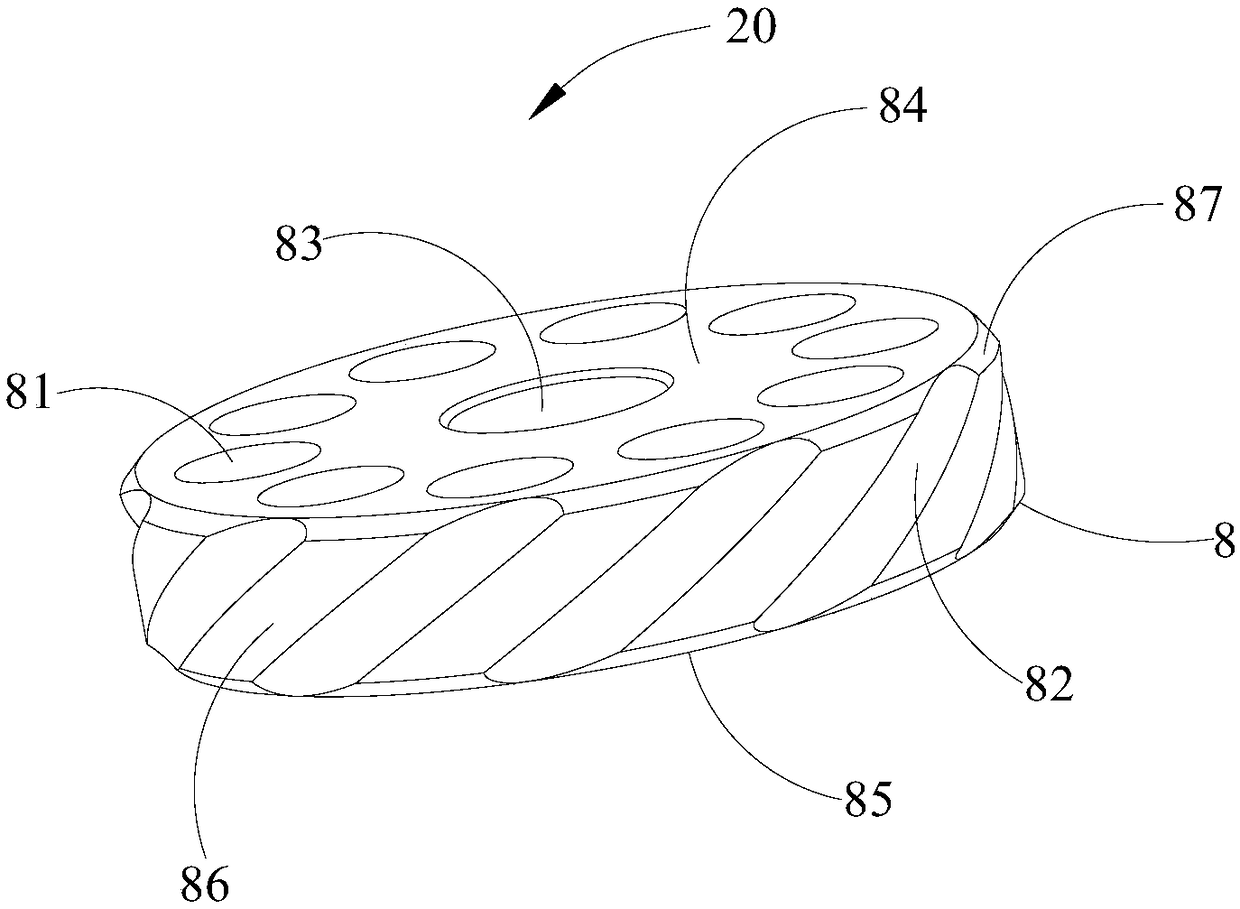

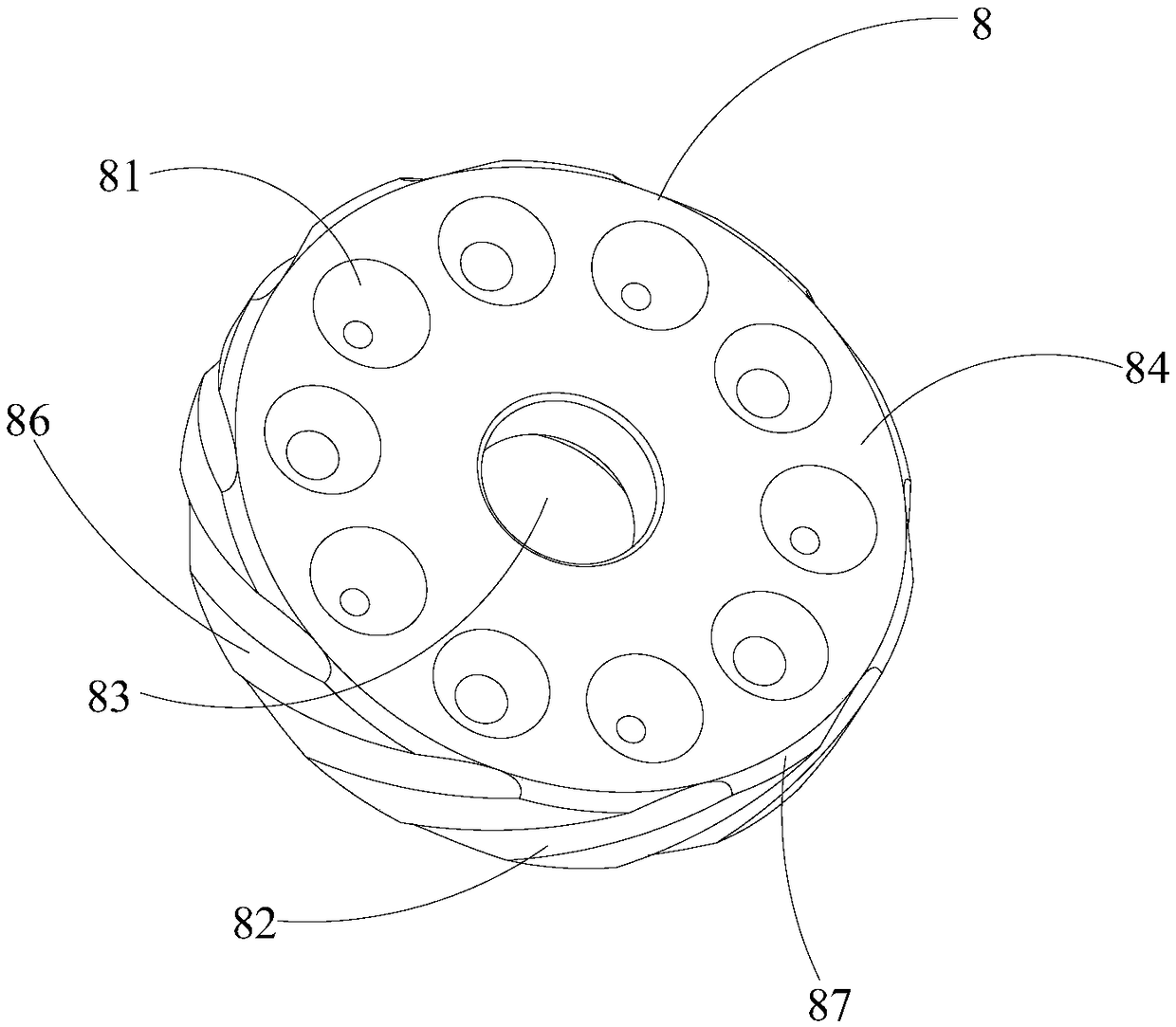

[0038] like Figure 1-3 .

[0039] An adaptive damping piston 20, which includes a piston body 8, the piston body 8 is a cylinder including side surfaces, an upper bottom surface 84 and a lower bottom surface 85, the upper bottom surface 84 and the lower bottom surface 85 are parallel to each other, the The piston body 8 includes a plurality of piston through holes 81 passing through the upper bottom surface 84 and the lower bottom surface 85, and the side surface is provided with a plurality of piston spiral grooves 82, and the two ends of each piston spiral groove 82 are respectively arranged on The upper bottom surface 84 and the lower bottom surface 85 .

[0040] As mentioned above, the self-adaptive damping piston 20 may include a piston body 8, and the piston body 8 is in the shape of a cylinder, specifically, it may be a cylinder or a regular polygon. The piston body 8 includes an upper bottom surface 84 and a lower bottom surface 85 parallel to each other, and there ...

Embodiment 2

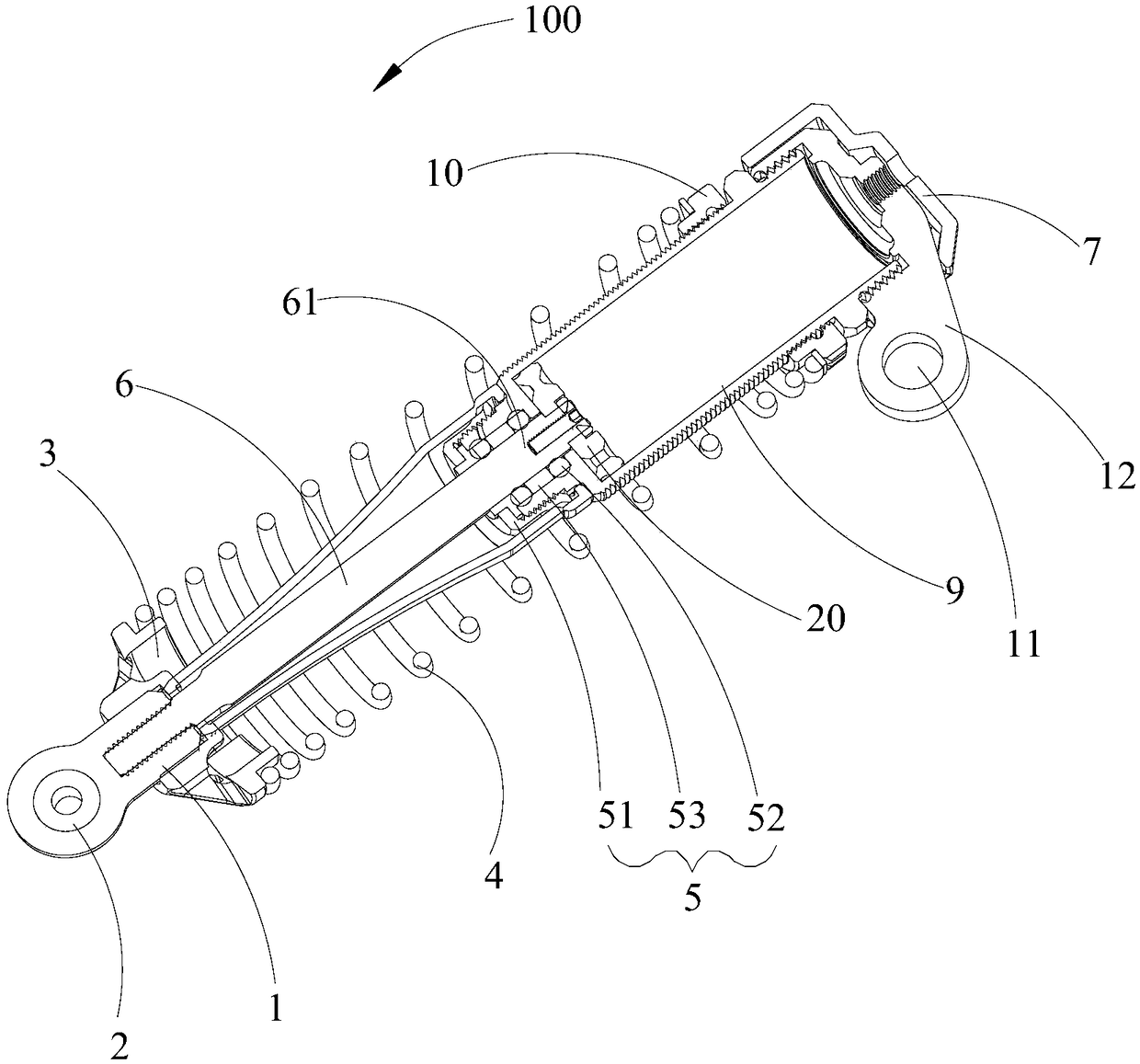

[0058] like Figure 1-3 .

[0059] The shock absorber 100 includes any one of the adaptive damping pistons 20 mentioned above, and the adaptive damping piston 20 is installed on the compression end 61 of the piston rod 14 inside the piston cylinder 9 .

[0060] The above means that the shock absorber 100 of this embodiment includes the adaptive damping piston 20 of the first embodiment. The self-adaptive damping piston 20 is installed in the piston rod 6, the piston rod 6 includes a connection end exposed to the piston barrel 9 and used to connect the fisheye bearing 2, the piston rod 6 also includes a connecting end arranged in the piston barrel 9, and connected to the self-adaptive damping piston 20. Adapt to the compression end 61 of the damping piston 20 for compressing the damping oil.

[0061] Specifically, the adaptive damping piston 20 may include a piston body 8, and the piston body 8 is in the shape of a cylinder, specifically, may be a cylinder or a regular polygo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com