A visual monitoring system and method for cold chain logistics

A monitoring system, cold chain logistics technology, applied in general control system, control/adjustment system, logistics, etc., can solve problems such as delayed delivery time, missed delivery time, and affecting the quality of goods, so as to avoid the loss of cold air and avoid delivery errors , the effect of shortening the delivery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

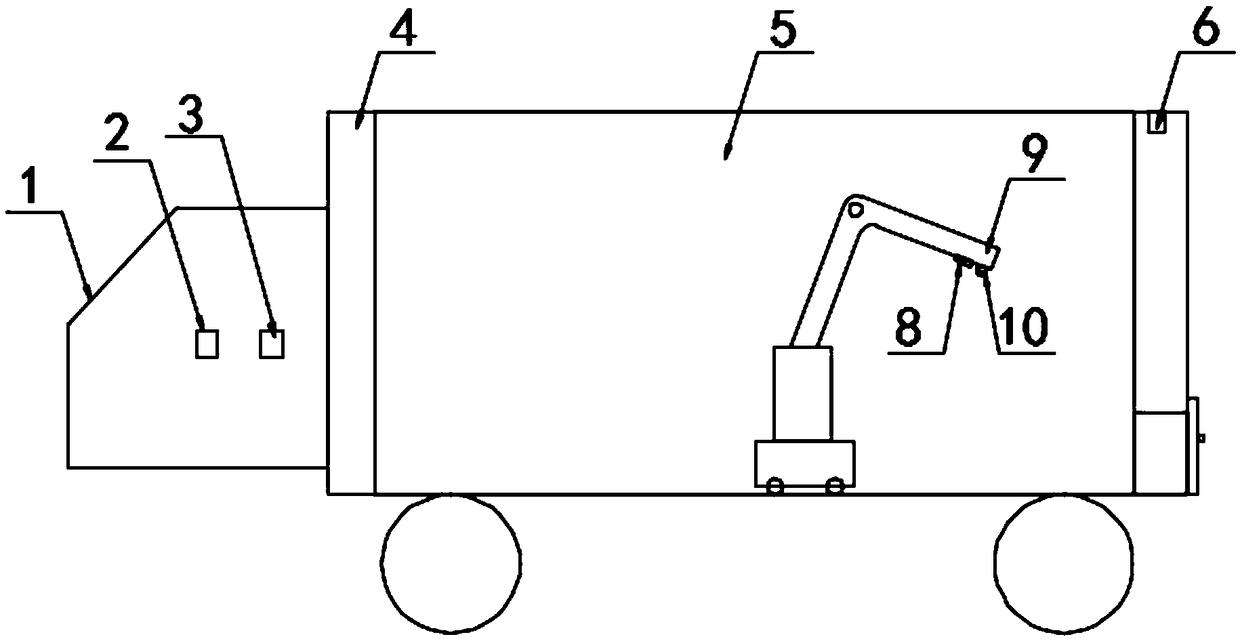

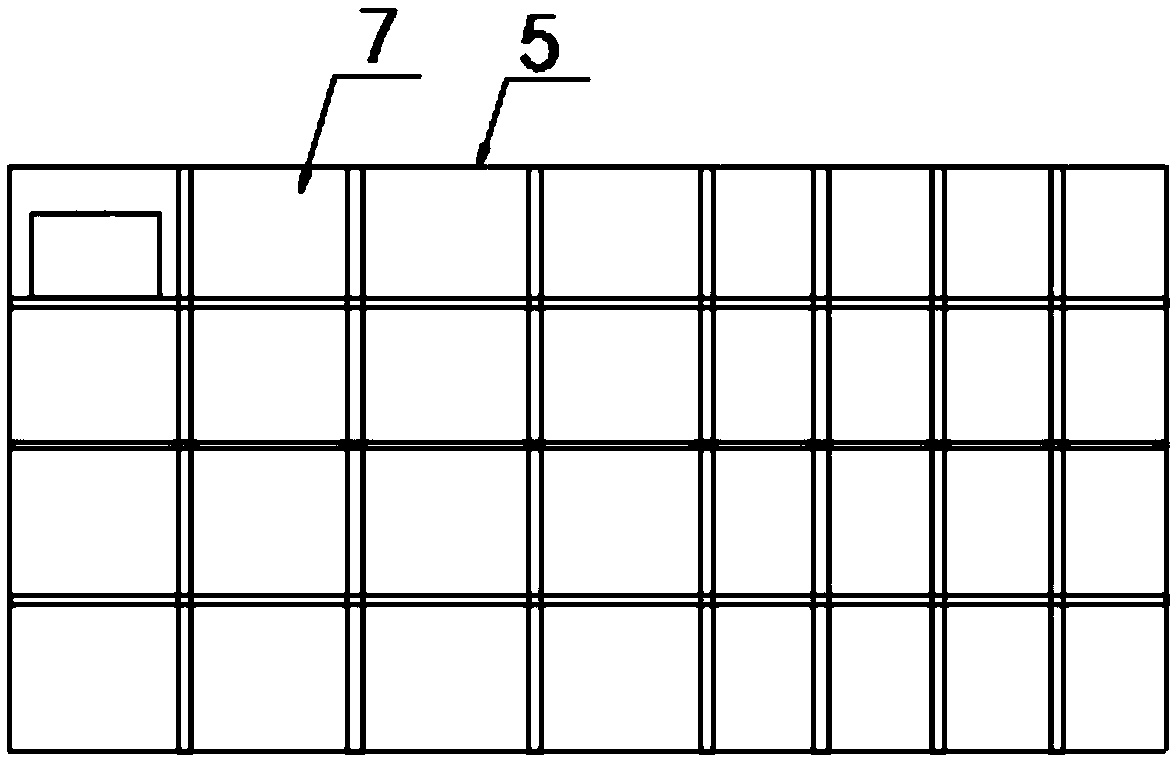

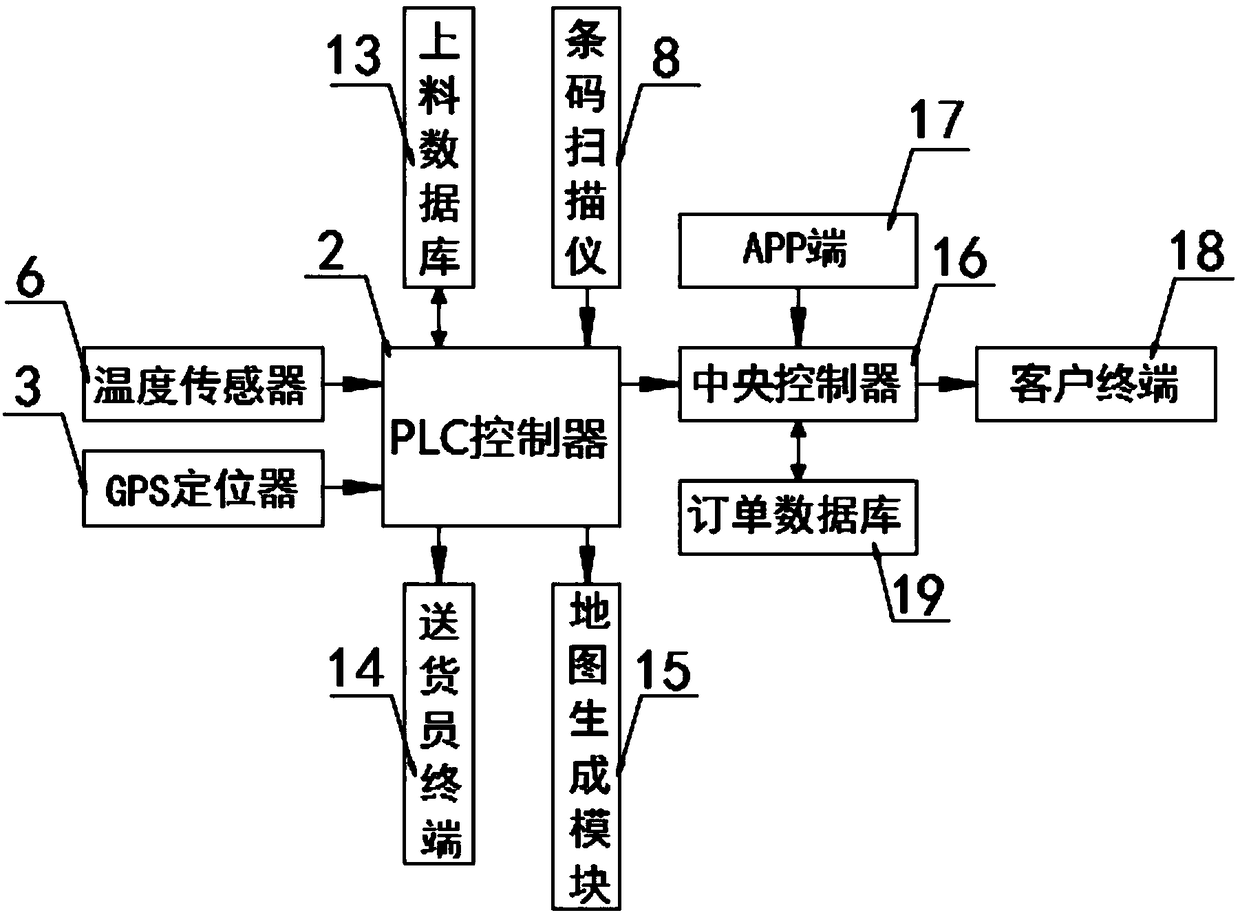

[0038] according to Figure 1-2 A cold chain logistics visualization monitoring system shown includes a transport vehicle 1, a PLC controller 2 and a GPS locator 3 are provided on the transport vehicle 1, and a cold store 4 is provided on the rear side of the transport vehicle 1, and the cold store 4. The inside is provided with a shelf 5 and a mechanical arm 9. The bottom of the mechanical arm 9 is provided with a four-wheel drive system. The inside of the mechanical arm 9 is provided with a single-chip microcomputer 24. The shelf 5 is set in multiples, and the mechanical arm 9 is set Between a plurality of shelves 5, a temperature sensor 6 is provided on one side of the shelf 5, a storage compartment 7 is provided on the shelf 5, goods are arranged inside the storage compartment 7, and a logistics list is provided on the goods, The logistics list is provided with a barcode, the order information of the goods is stored inside the barcode, a barcode scanner 8 and a camera 10 are...

Embodiment 2

[0044] The present invention also provides a method for visual monitoring of cold chain logistics, and the specific implementation steps are as follows:

[0045] Step 1: The APP terminal 17 receives the order, and the order information is automatically stored in the order database 19 through the central controller 16, and the orders in the same area are uniformly delivered, and the central controller 16 sends the order information to the PLC controller 2, and the PLC controller 2 Store the order information in the material loading database 13;

[0046] Step 2: When loading goods into the warehouse, the deliveryman opens the sliding door 11 and places the goods on the storage table 12. The single-chip microcomputer 24 controls the operation of the mechanical arm 9. When the mechanical arm 9 picks up the goods, the barcode scanner 8 at the bottom will The bar code on the goods logistics list is scanned and identified, and the order information of the identified goods is checked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com