Bus conductor connector

A connector and conductor technology, which is applied in the field of busbar conductor connectors, can solve the problems of inconvenient disassembly and assembly operations, high production cost investment, and long time consumption, so as to simplify the connection process of phase line conductors, reduce the workload of installation and connection, Effect of securing contact continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

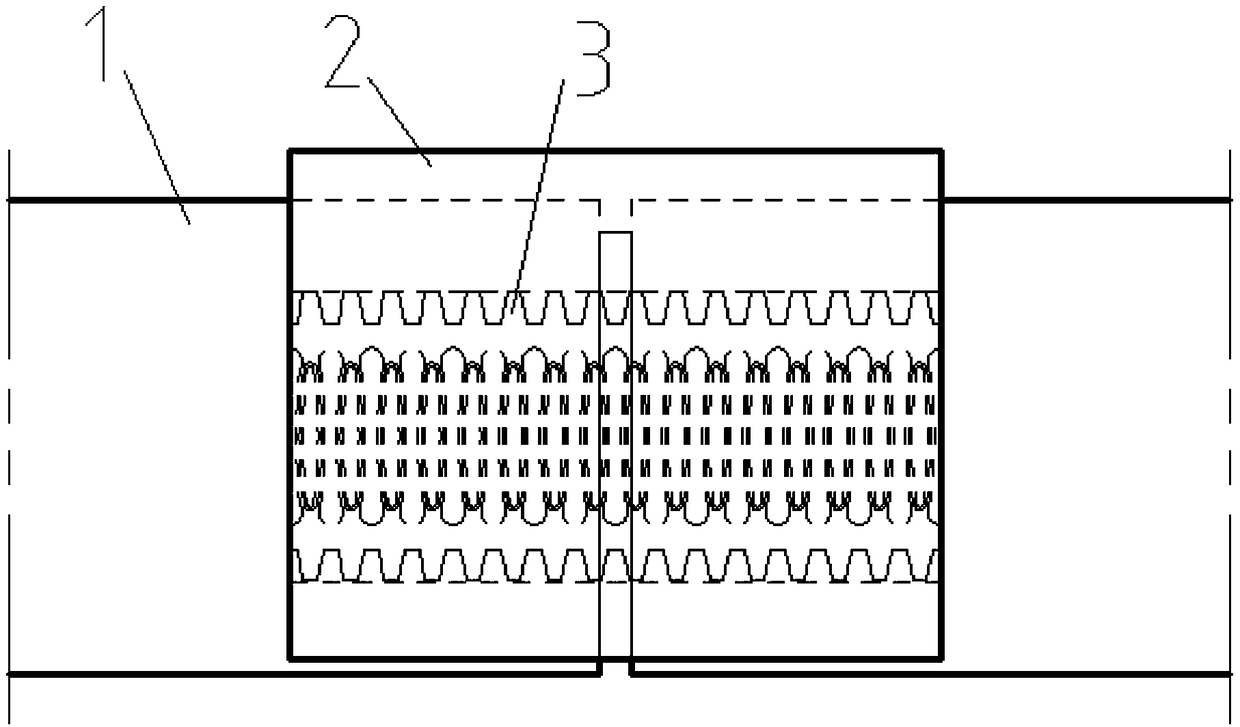

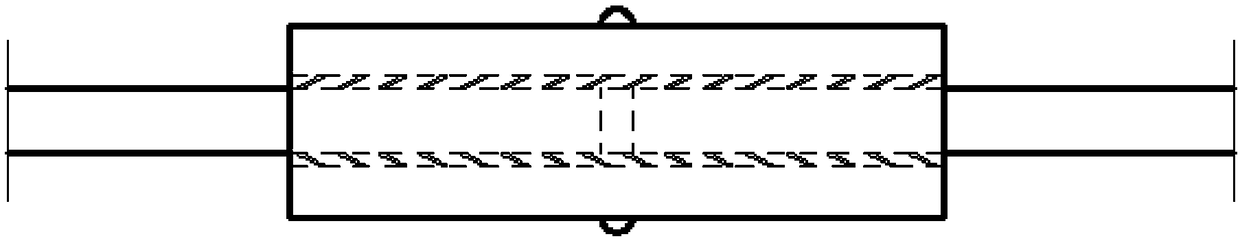

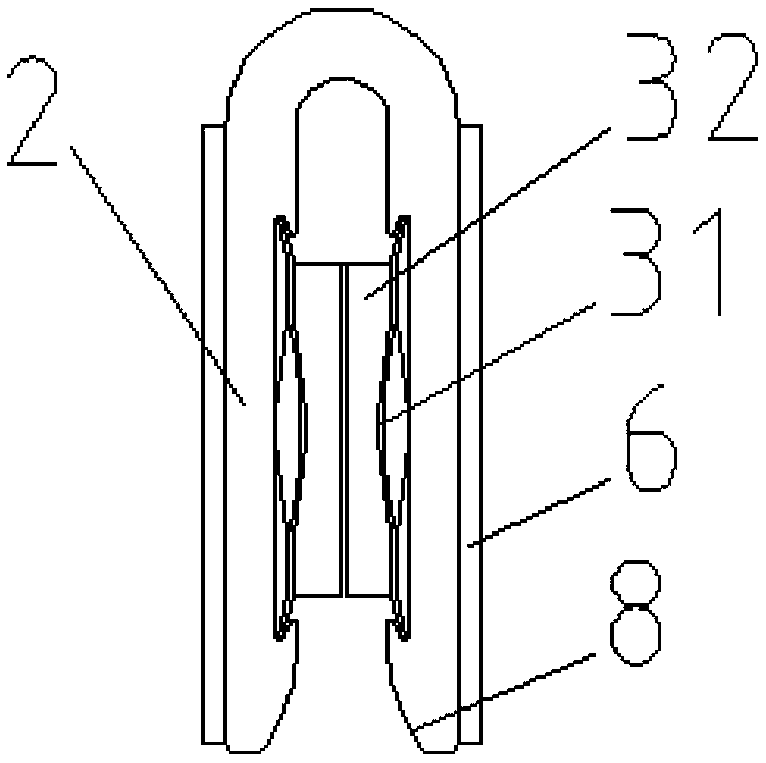

[0021] As shown in the figure, a busbar conductor connector includes two upper and lower sides, and a connecting section connected to one side of the two upper and lower sides, forming a connection with an opening on one side and a cross-sectional "U" shape. Conductor 2, horizontal "U"-shaped connecting conductor 2 The space between the upper and lower sides constitutes a socket slot 4 that can be inserted into a pair of adjacent pair of bus duct product phase line conductors 1, and the adjacent one For bus duct products, the phase line conductor 1 can be inserted into the socket slot horizontally from the opening side of the horizontal "U"-shaped connecting conductor 2 at the same time, and is connected and conducted through the horizontal "U"-shaped connecting conductor; the socket slot 4 is up and down The inner walls are respectively provided with card slots 5 extending transversely, and the sheet-shaped strip-shaped elastic conductors 3 are respectively clamped in the card...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com