Vehicular chain screen for separating sludge from sundries

A vehicle-mounted, sludge technology, applied in the fields of filtration and separation, sludge treatment, separation methods, etc., can solve the problems of secondary environmental pollution, large fluidity, large volume, etc., and achieve sufficient installation space, light weight, and connection mode simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

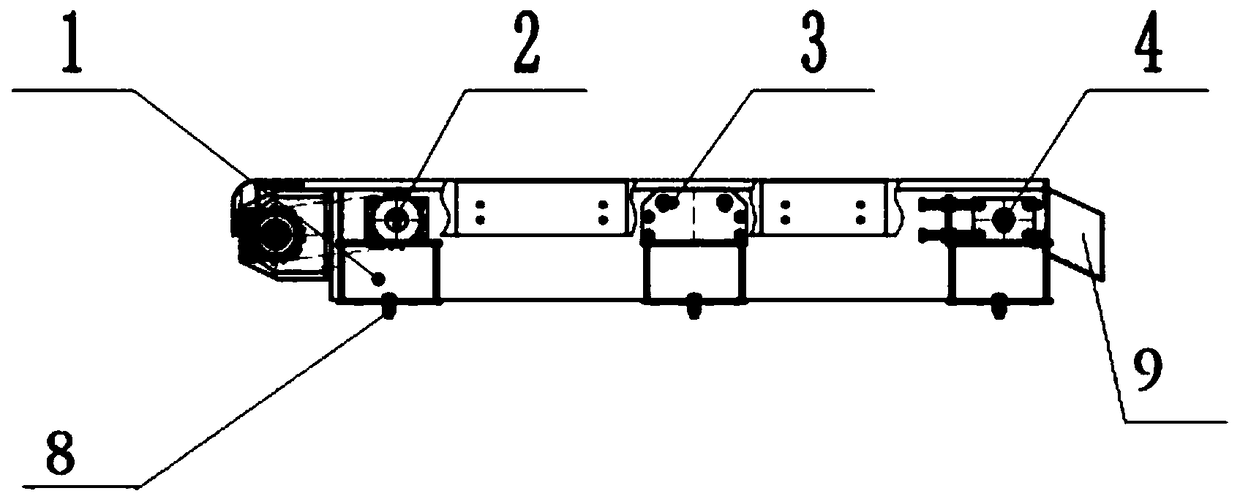

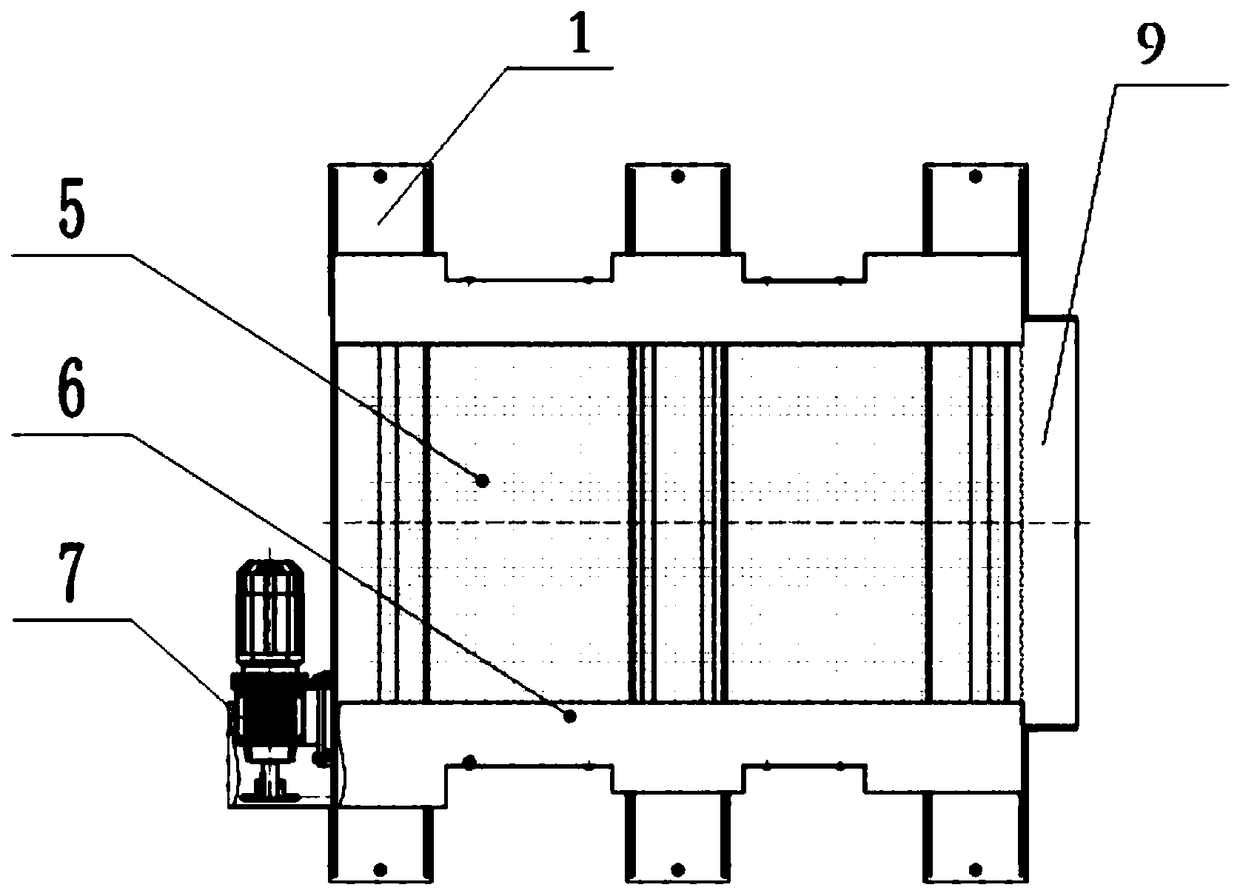

[0021] A vehicle-mounted chain screen for separating sludge and sundries, comprising a main frame, a plurality of supports 1 are arranged under the main frame, and the supports 1 are connected with a sludge collection box through bolts 8; There is a driving shaft 2 and a driven shaft 4, and the driving shaft 2 and the driven shaft 4 are respectively located at both ends of the main frame;

[0022] A deceleration motor 7 is installed on one side of the main frame, and a slag discharge tank 9 is provided on the other side of the main frame, and the slag discharge tank 9 is used to discharge sundries;

[0023] The drive shaft 2 is connected with the reduction motor 7 through a sprocket, and the driven shaft 4 is connected with the drive shaft 2 through a sprocket; the driven shaft 4 is provided with a tensioning device; the reduction motor 7 drives the drive through the sprocket Axis 2, the drive shaft 2 drives the driven shaft 4 through the sprocket;

[0024] The driving shaft ...

Embodiment 2

[0029] A working method of a vehicle-mounted chain screen for separating sludge and sundries, comprising the following steps:

[0030] S1: Place the chain sieve on the sludge collection box of the sludge transfer vehicle, and start the reduction motor 7;

[0031] S2: After the reduction motor 7 is running, the driving shaft 2 and the driven shaft 4 are also running, driving the mesh belt 5 to circulate;

[0032] S3: put the sludge to be treated on the mesh belt 5, with the circular movement of the mesh belt 5, the liquid sludge and fine sand will flow into the sludge collection box from the mesh of the mesh belt 5, and the remaining miscellaneous The material will move with the mesh belt 5 to the slag discharge groove 9 on one side of the main frame, and then be discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com