Method and device for automatically controlling speed of generation of nitrogen oxide from nitric acid by nitration and oxidation

A nitrogen oxide and nitric acid technology, applied in chemical instruments and methods, feeding devices, chemical/physical/physicochemical processes, etc., can solve the problem of affecting production progress, wasting nitrogen oxide resources, and the difference in processing speed of absorption equipment for nitrogen oxide production speed Far away and other problems, to achieve the effect of reducing backflow dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

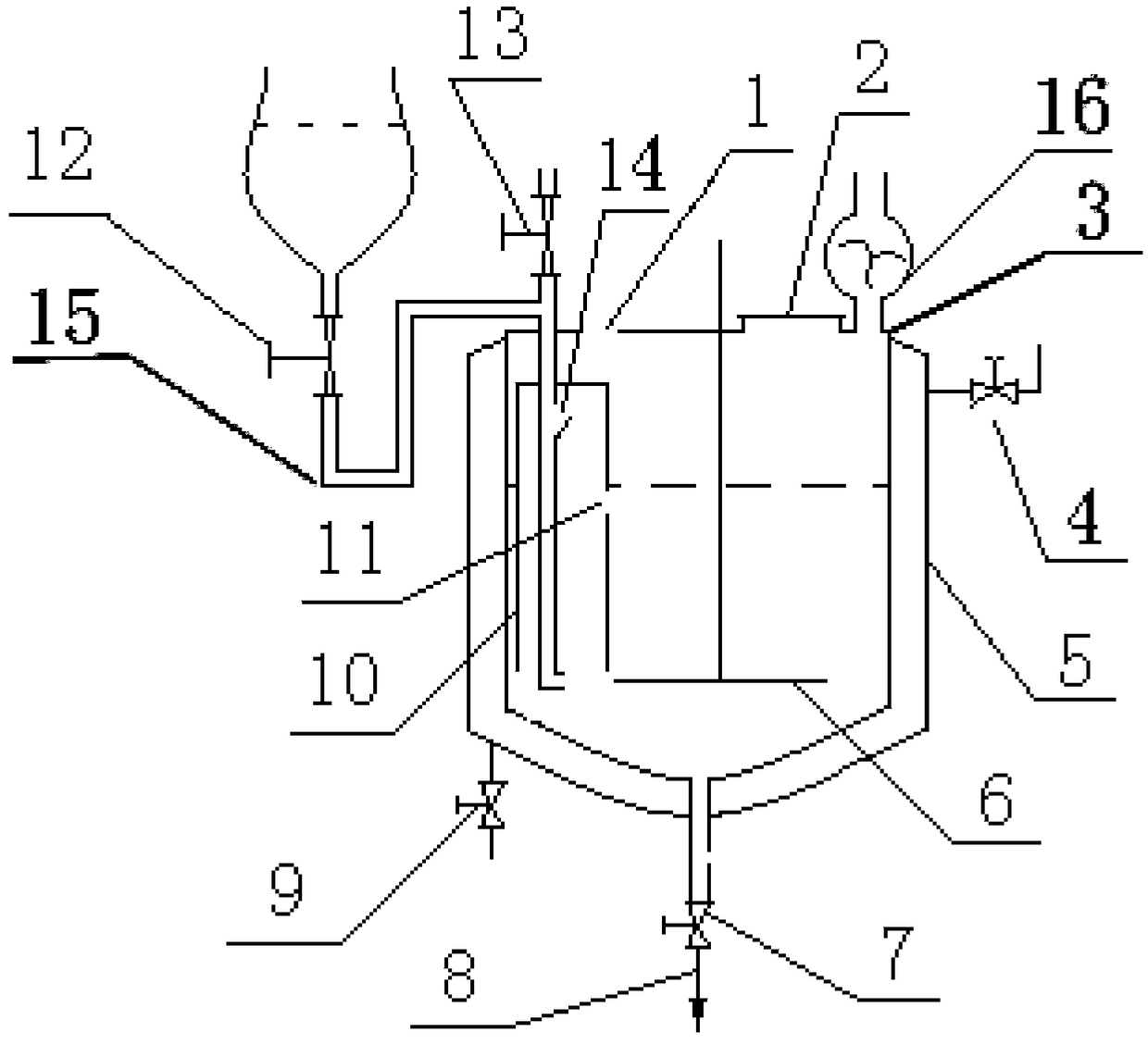

[0034] figure 1 The structure of the device provided by the present invention is shown. A device for automatically controlling the speed of nitric acid nitration and oxidation to produce nitrogen oxides, comprising a reaction kettle 5, a speed controller 10, a return pipe 15 and a dropping funnel with a dropping valve 12. The reaction kettle 5 has an upper cover 2, and the upper cover is provided with an air inlet 1 and an air outlet 3; an agitator 6 is arranged inside; a drain pipe 8 with a drain valve 7 is arranged at the bottom. Preferably, a fan 16 is provided at the air outlet 3 . Preferably, the reactor 5 has a two-layer structure, the inner layer is used for raw material reaction, the outer layer is used for condensation or heating of the introduced medium, the upper end of the outer wall is provided with an inlet valve 4, and the lower end is provided with an outlet valve 9. The air outlet 3 is connected to corresponding nitrogen oxide treatment equipment, such as an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com