Pebble coal bucket jacking and sealing system of coal mill

A sealing system and coal mill technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve problems such as serious pollution, spillage of stone coal, etc. Possible Effects of Ash Spill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

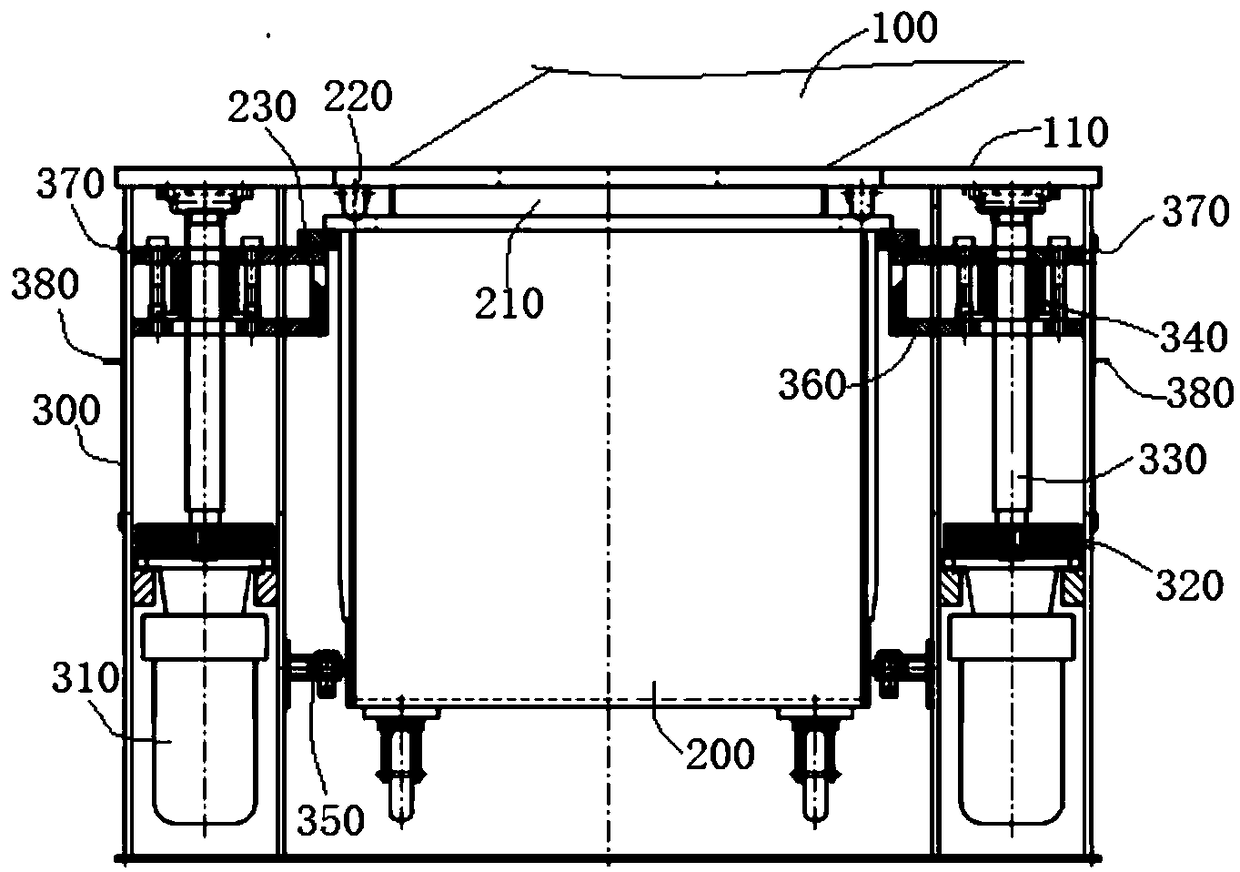

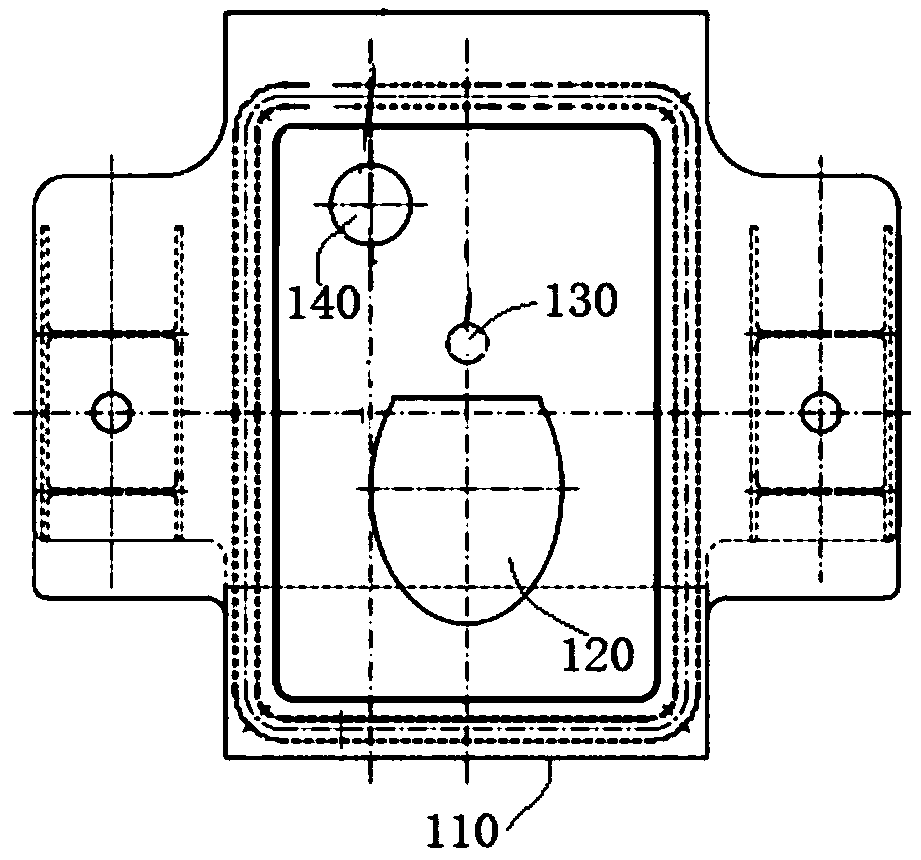

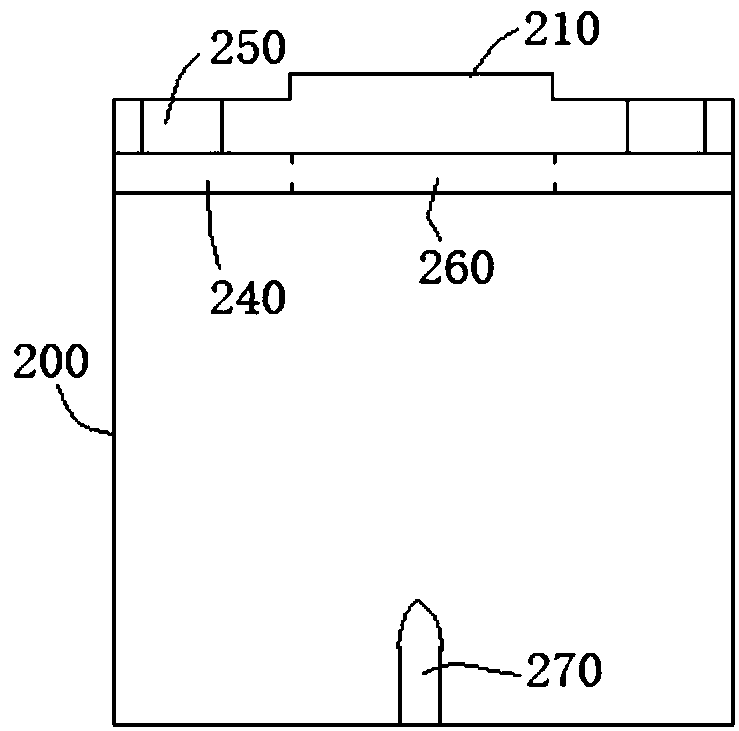

[0036] Such as Figure 1-Figure 3 As shown, the coal mill stone hopper jacking sealing system of this embodiment includes a stone coal hopper 200, a fixed plate 110 arranged at the bottom of the slag discharge pipe 100, and fixed brackets 300 arranged on both sides of the stone coal hopper 200. The slag pipe 100 extends obliquely downward and is provided with a fixed plate 110 at the bottom, and the top of the fixed bracket 300 is connected with the fixed plate 110. A slag receiving port 210 matching with the slag discharge port 120 is provided, and a jacking unit for driving the gravel coal hopper 200 to lift is provided on the fixed bracket 300 . Through the driving action of the jacking unit, the gravel coal hopper 200 can be lifted up and down, and the slag connecting port 210 on the top of the gravel coal hopper 200 can be raised to directly below the slag discharging port 120 when slag discharge is required, and the slag connecting port 210 and the slag discharging port ...

Embodiment 2

[0039] The basic structure of the coal pulverizer stone coal hopper jacking sealing system of this embodiment is the same as that of Embodiment 1. Furthermore, the jacking unit in this embodiment includes a motor 310, a lead screw 330 and a screw nut 340 that are co-located, and the motor 310 The output end of the output end is connected to one end of the lead screw 330 through the reducer gear 320, and the other end of the lead screw 330 is connected to the bottom of the fixed plate 110 and rotated. The slider 360 is provided with a support block 230 on the outside of the top of the gravel coal hopper 200 , and the slider 360 is correspondingly located below the support block 230 . In this embodiment, through the cooperation of the conventional lead screw 330 and the screw nut 340 in the industry, the slider 360 is fixed on the screw nut 340, and the rotary motion of the lead screw 330 is converted into the linear motion of the slider 360, so as to realize the control of the s...

Embodiment 3

[0043] The basic structure of the coal pulverizer stone coal hopper lifting sealing system in this embodiment is the same as that in Embodiment 2. Furthermore, in this embodiment, the lower part of each fixed bracket 300 is respectively provided with a position guide 350, and the position guides on both sides 350 relatively extends toward the direction close to the gravel coal hopper 200 . The guide piece 350 guides and limits the gravel coal hopper 200 from both sides, and the end of the guide piece 350 close to the gravel coal hopper 200 can be set as a roller structure to prevent the gravel coal hopper 200 from shifting left or right or shaking during the lifting process phenomenon, and the position guide 350 can be set as a telescopic type, for example, the telescopic control of the cylinder telescopic rod to the position guide 350 can be realized by connecting the cylinder. 200. Correspondingly, the two sides of the gravel coal hopper 200 can respectively be provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com