Anti-fingerprint spraying coating equipment with incoming material cleaning function

A coating equipment, anti-fingerprint technology, applied in the direction of coating, spray device, cleaning method and utensils, etc., can solve the problems of production waste, manpower consumption, secondary pollution, etc., to reduce pollution and damage, easy adjustment, automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be described in detail with reference to the accompanying drawings.

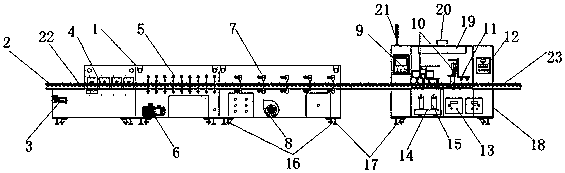

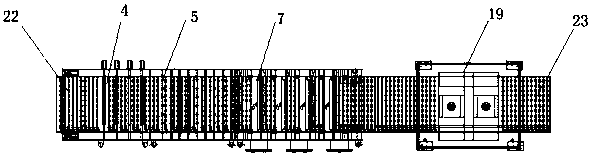

[0021] see figure 1 and figure 2 , the present invention provides a kind of anti-fingerprint spray coating equipment including cleaning of incoming materials, including a substrate transmission system, a flat plate cleaning area and a spray coating area, wherein the substrate transmission system includes a transmission mechanism 2 and a transmission motor 3, on the transmission mechanism 2 There is a cleaning frame 1 and a spraying frame 18. The flat plate cleaning area includes a cleaning frame 1, a brush cleaning device 4, a spraying device 5, an air drying device 7, a water pump 6 and a high-pressure fan 8. The spray coating area includes a spraying frame 18. Plasma device 9, spraying device 11, servo motor 10, electronic scale 14 and liquid medicine tank 15. The base material flows in from the feed port 22 through the transmission mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com