Cleaning system used for metal mask plate

A metal mask and cleaning system technology, which is applied in the field of metal mask cleaning, can solve problems such as high system input cost and operating cost, unreasonable structural design, and difficulty in meeting user requirements, achieving a high degree of automation, fixed and reliable , reduce the effect of volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

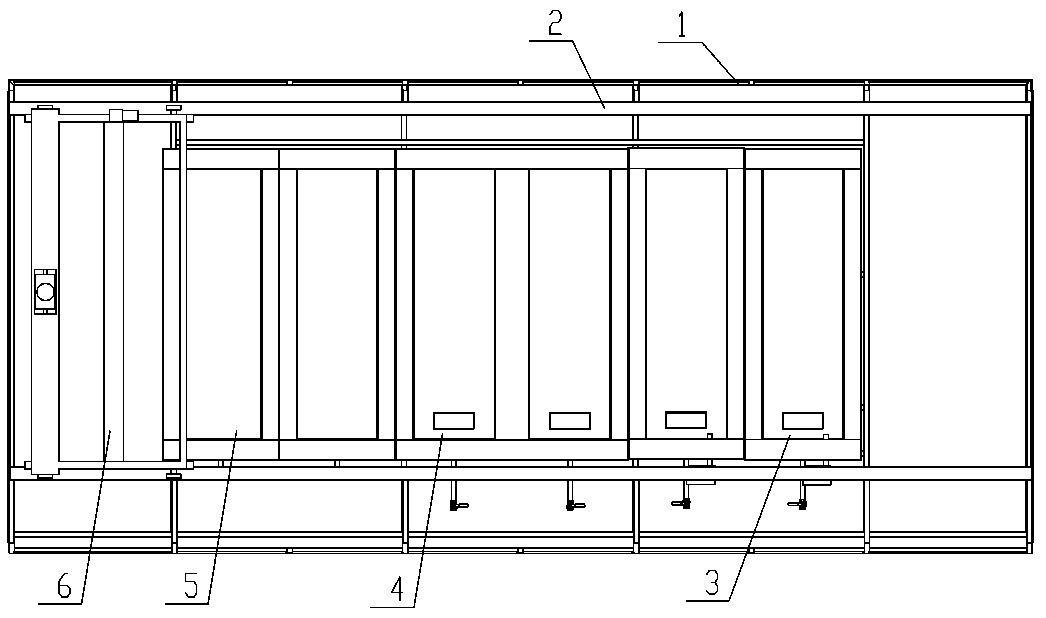

[0044] see figure 1 , Figure 14 , the present embodiment includes a closed workshop 1, a row of several cleaning tanks is placed on the ground in the workshop 1, a dehydration tank 5 is installed at the rear end of the cleaning tank, and two longitudinal beams 2 are installed on the top of the cleaning tank in the workshop 1. A manipulator 6 is installed on the longitudinal beam 2, and the cleaning system also includes a spreader 7 for loading metal mask plates. The manipulator 6 can lift or translate the spreader 7; the cleaning tank includes a bubbling cleaning tank 3, an alcohol cleaning tank 4.

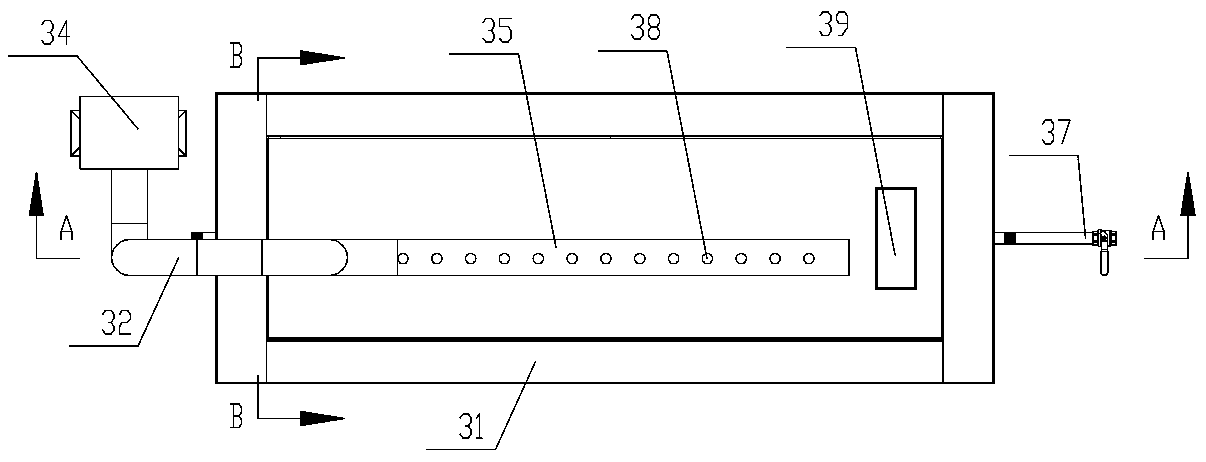

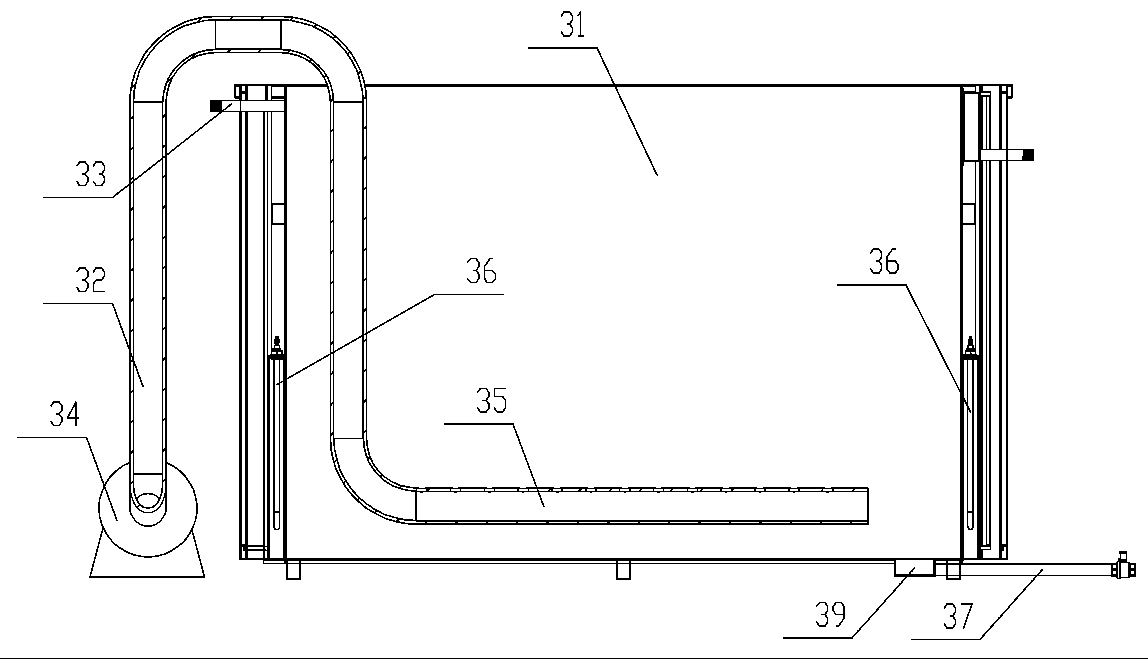

[0045] see Figure 2-4 The bubbling cleaning tank 3 in this embodiment comprises a rectangular tank 31 with an open upper end, a water inlet pipe 33 is installed on the side wall of the tank body 31, a water outlet pipe 37 is installed at the bottom of the tank body 31, and a water outlet pipe 37 is installed on the outer side of the tank body 31 A blower 34, the air outlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com