Heat-free temperature-controlled blending silo

A mixing bin and temperature-controlled technology, which is applied in the field of heating-free temperature-controlled mixing bins, can solve problems such as easy blockage of fibers and matrix materials, reduced performance of fiber-reinforced composite materials, and inconvenient maintenance of the bin structure. , to achieve the effect of good sealing effect, short mixing time and not easy to lose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

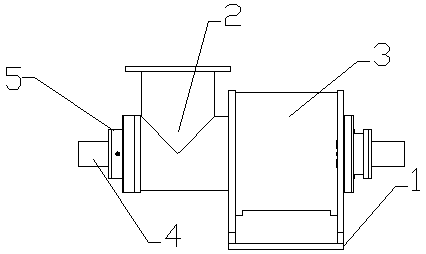

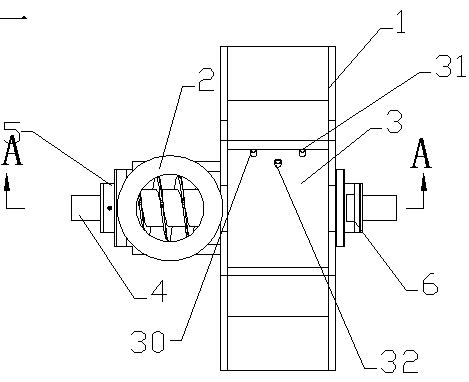

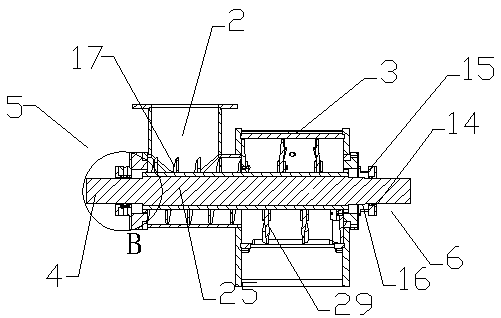

[0046] Example 1, such as Figure 1-13 As shown, a heating-free temperature-controlled mixing bin includes a frame 1, a feeding bin 2 and a mixing bin 3 are arranged on the rack 1, and a feeding bin 2 is arranged at the front end of the mixing bin 3, and the feeding bin 2 is used for It is used to push the fiber and matrix material to the mixing bin 3, which can effectively avoid the blockage of the fiber and matrix material during the feeding process. The feeding bin 2 and the mixing bin 3 are relatively closed cavity structures. The feeding bin 2 and the The mixing bin 3 is provided with a transmission main shaft 4, the transmission main shaft 4 is provided with a spiral blade 17 on the part of the feeding bin 2, and the transmission main shaft 4 is provided with a stirring blade 29 on the part of the mixing bin 3;

[0047]The mixing bin 3 is a split structure, the mixing bin 3 is divided into upper and lower parts, the bin wall of the mixing bin 3 is a double-layer structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com