Online testing automatic device

A technology for automated equipment and online testing, applied in electronic circuit testing, measuring device shells, stacking of objects, etc., can solve the problem of semi-automatic equipment requiring manual operation, and achieve the effect of improving work efficiency and automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

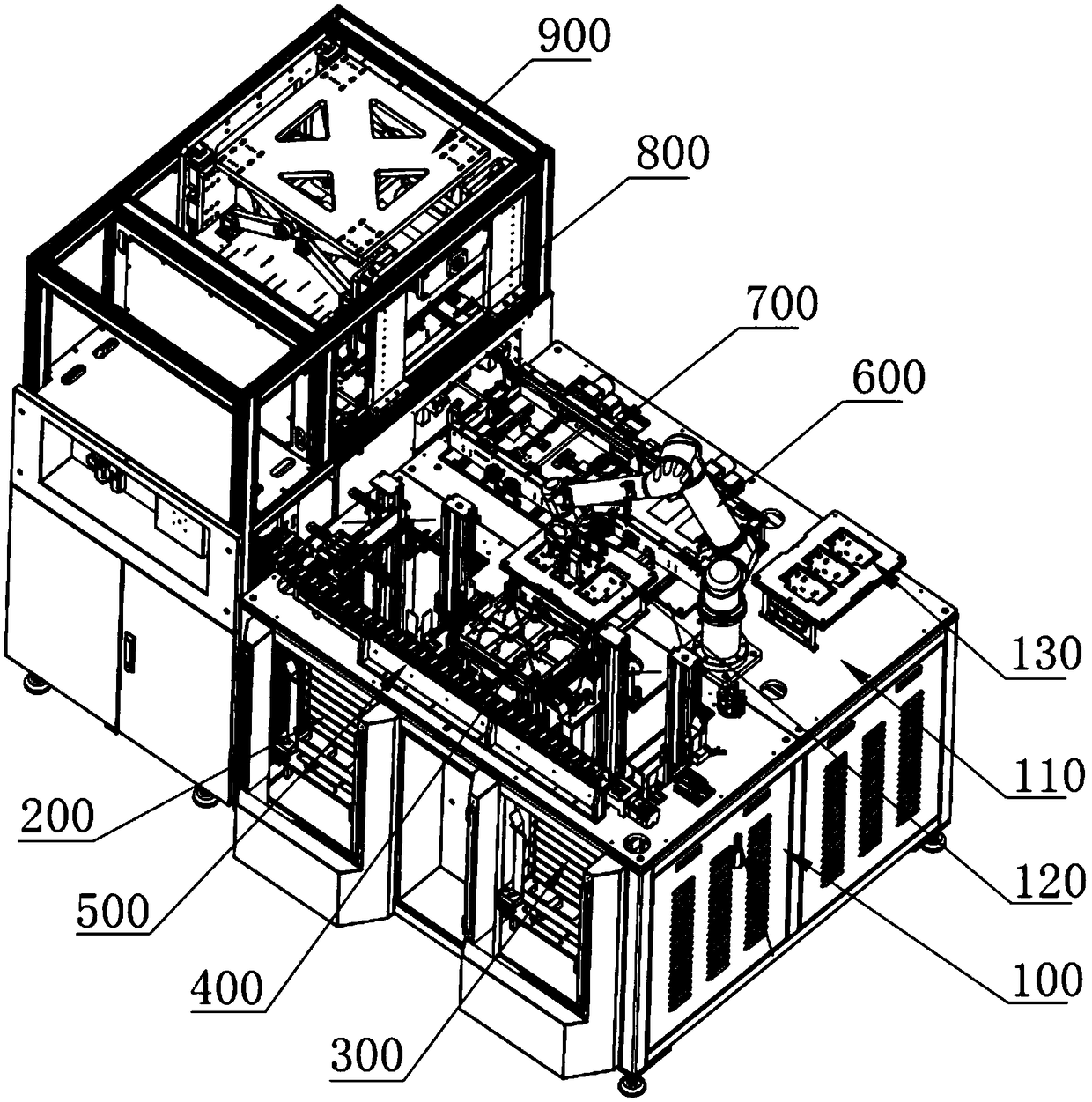

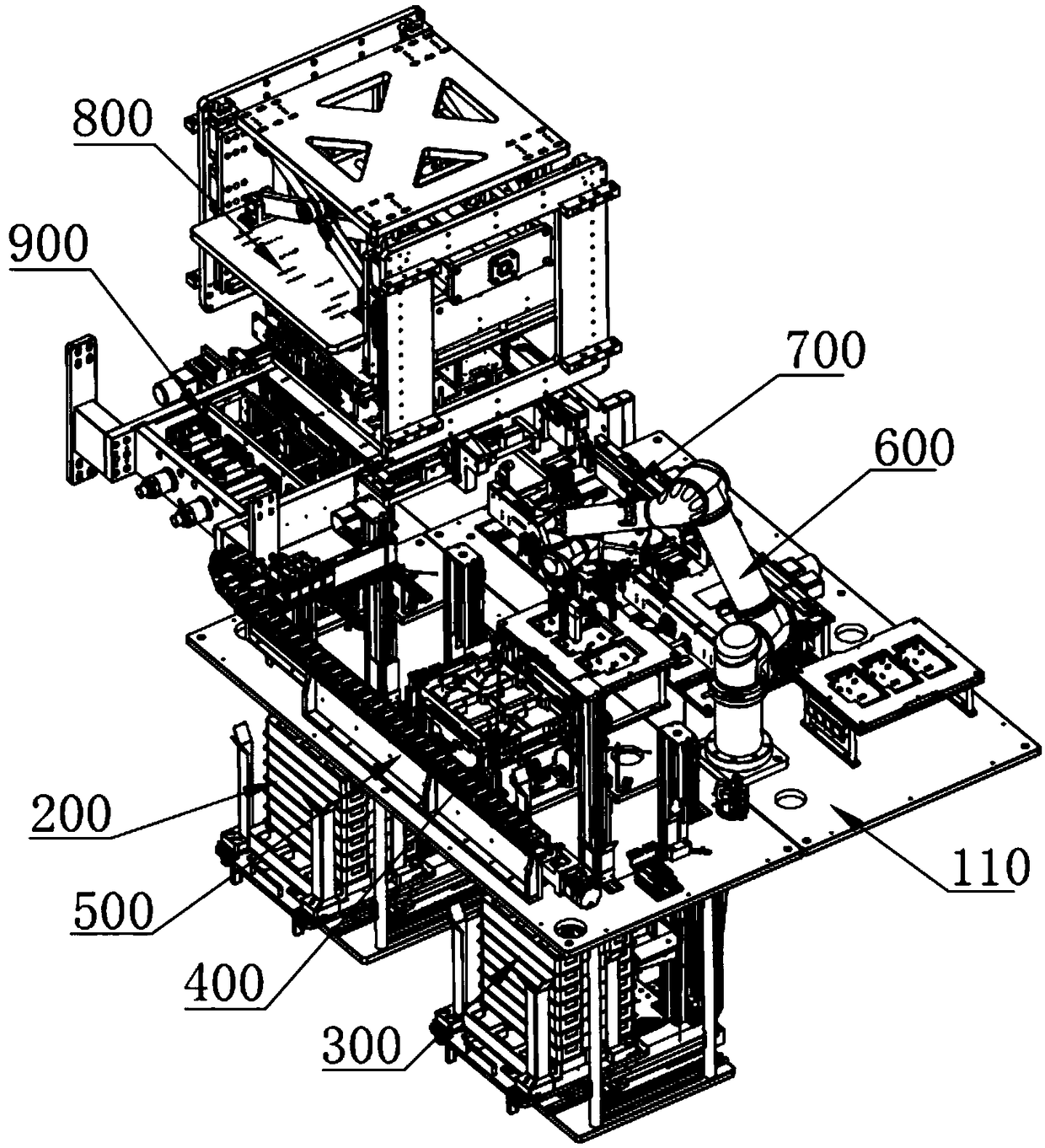

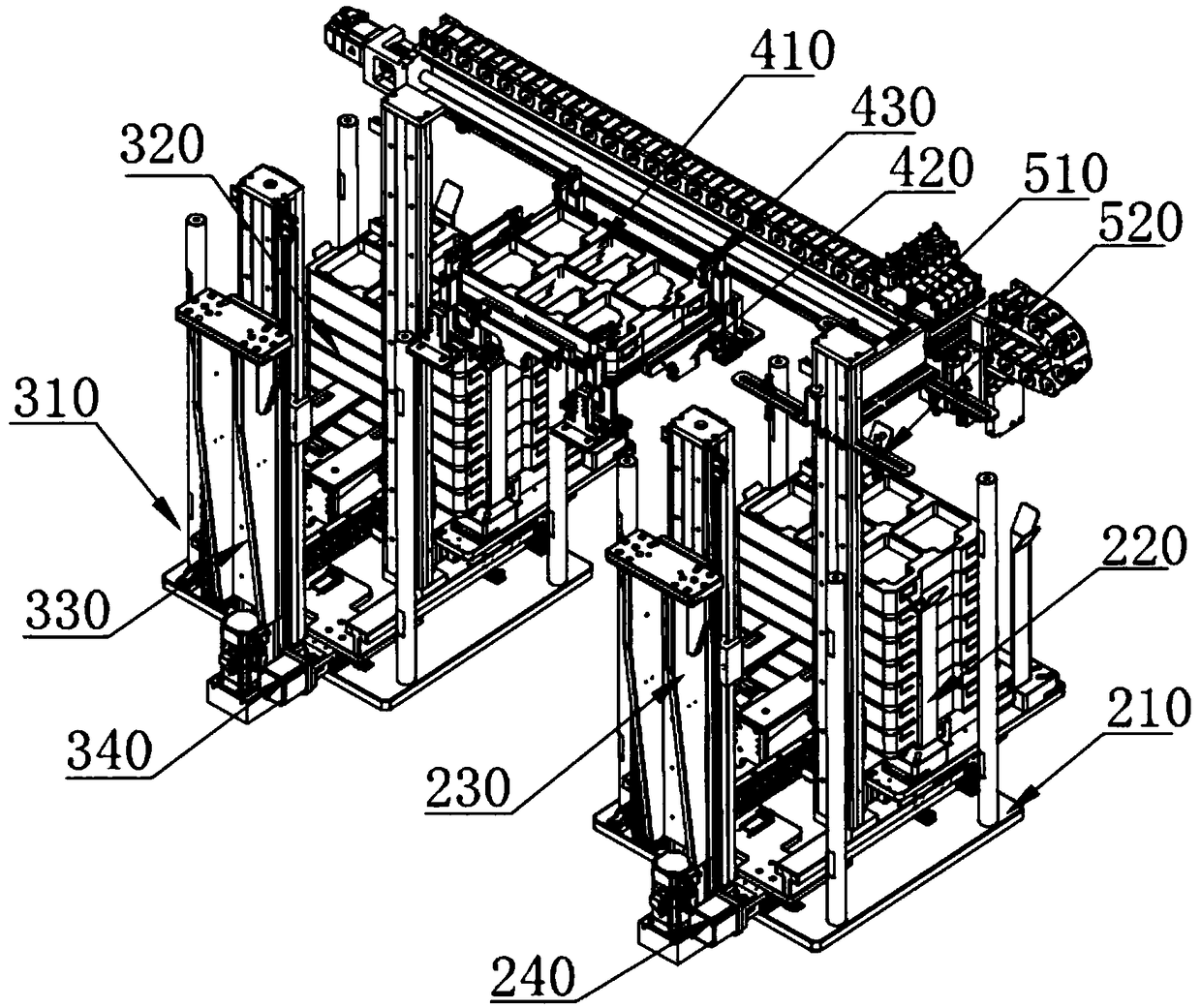

[0026] Such as Figure 1 ~ Figure 2 As shown, a kind of on-line testing automation equipment, comprises frame 100, is installed on the workbench 110 of frame 100, is respectively installed on the feeding mechanism 200 of workbench 110 both sides and unloading mechanism 300, is positioned at feeding mechanism 200 and The storage mechanism 400 between the unloading mechanism 300, the retrieving mechanism 500 installed on the workbench 110 and transmitted to the feeding mechanism 200, the storage mechanism 400 and the unloading mechanism 300, and the reclaiming manipulator 600 installed on the surface of the workbench 110 , installed on the workbench 110 near the good product preparation platform 120 of the storage mechanism 400 and the defective product storage platform 130 near the retrieving manipulator 600, installed on the workbench 110 near the conveying mechanism 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com