Seamless steel rail insulation safety device

A technology of seamless steel rail and insulation safety, applied in the direction of rail joints, railway fixtures, rails, etc., can solve the problems of reduced rail weld strength, poor reinforcement and insulation effect, etc., to achieve good reinforcement effect and good reinforcement effect. , good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

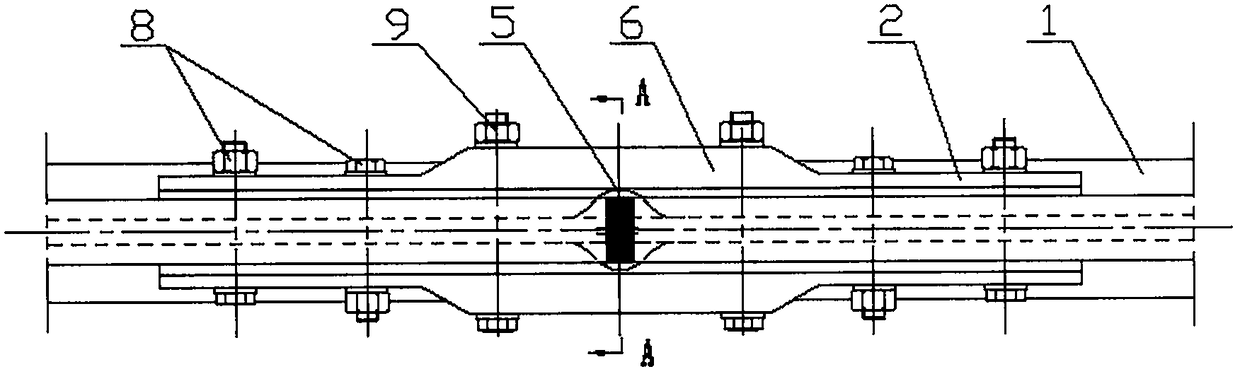

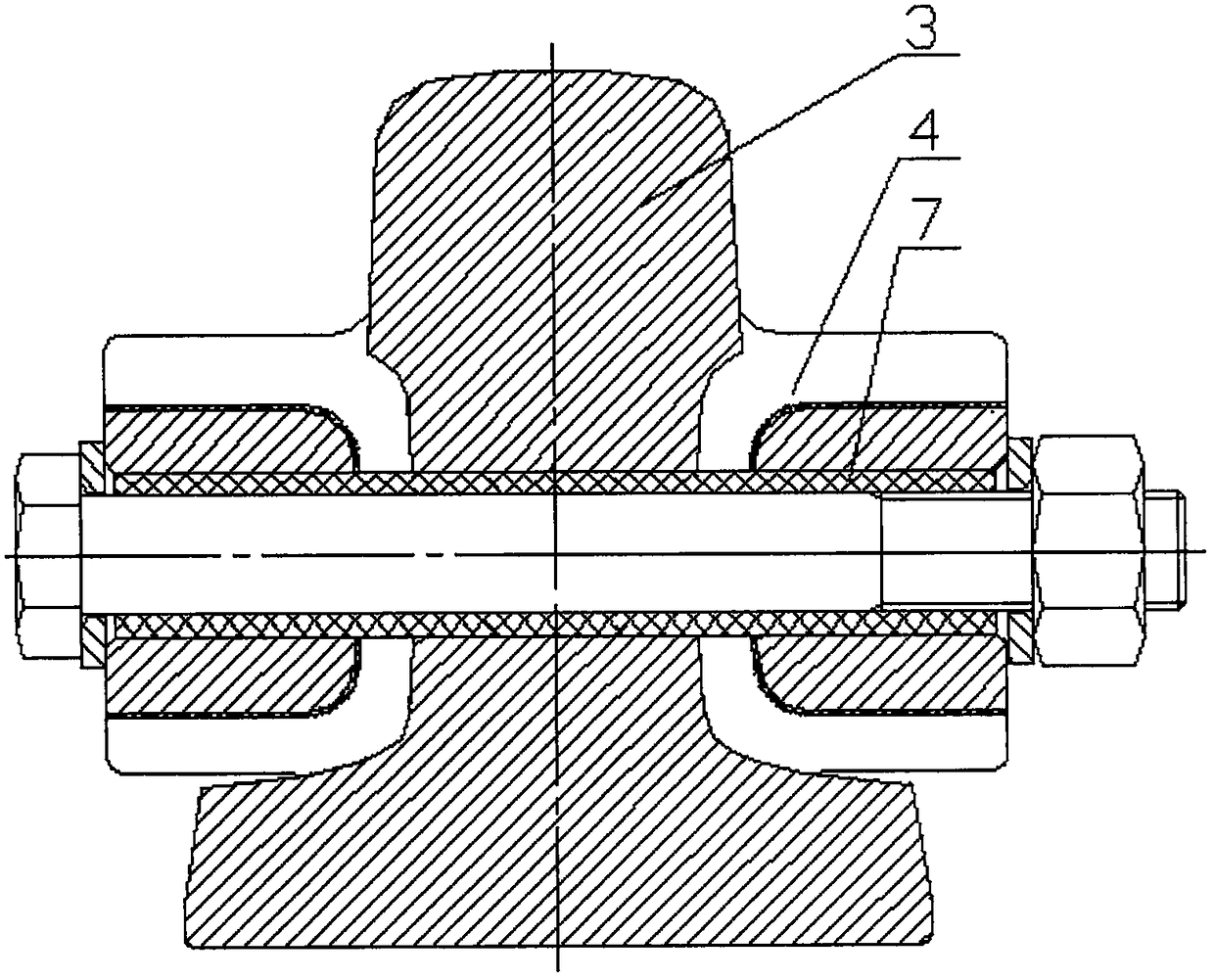

[0037] 1. The structure of the seamless rail insulation safety device

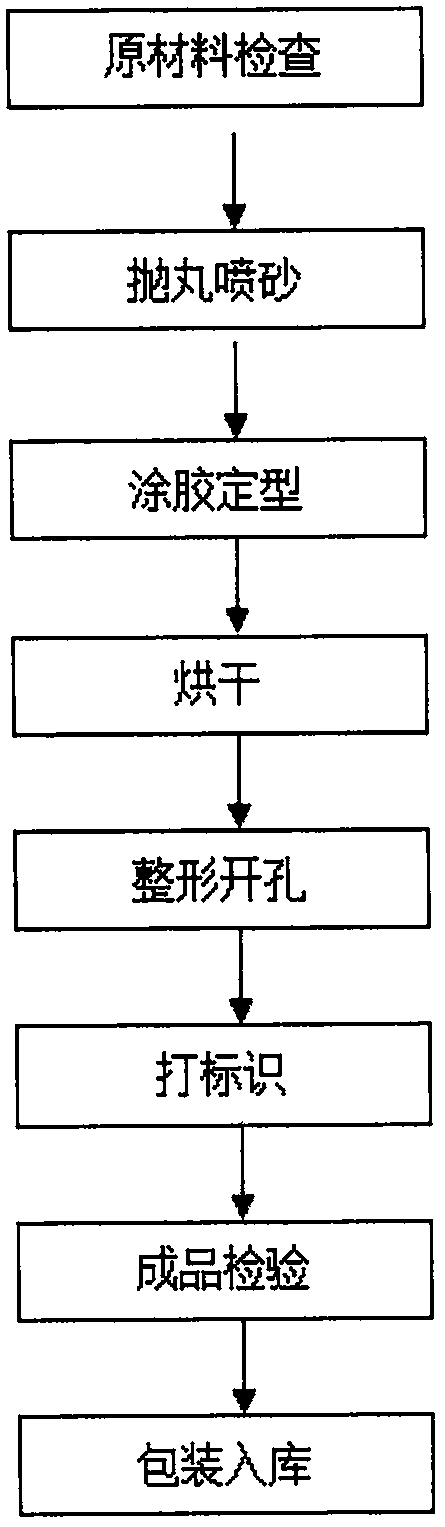

[0038] Such as figure 1 and figure 2A seamless rail insulation safety device is shown, which is used at joints of seamless rails welded on site. The center is aligned with the rail weld 3, and the surface of the rail insulating splint 2 is attached with an insulating material; the bonding surface of the rail insulating splint 2 and the rail 1 is bonded with an insulating layer 4, and the center of the bonding surface An arc surface 5 of R40mm and depth of 30mm is processed at the place, and an insulating layer 4 is bonded there; The thickness is 30mm larger than that of the left and right parts; the overall length of the rail insulation splint 2 is increased by 103mm; the raw material of the rail insulation splint 2 is 40Cr steel; the two rail insulation splints 2 are fixed by 6 bolts Together, an insulating sleeve 7 is provided in the mounting hole of the bolt.

[0039] In this embodiment, the left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com