Method for establishing welding spot quality detection standard

A technology for solder joint quality and testing standards, applied in the analysis of solids, instruments, and materials using sonic/ultrasonic/infrasonic waves. It can solve problems such as limitations, limited data volume, and low efficiency. time consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

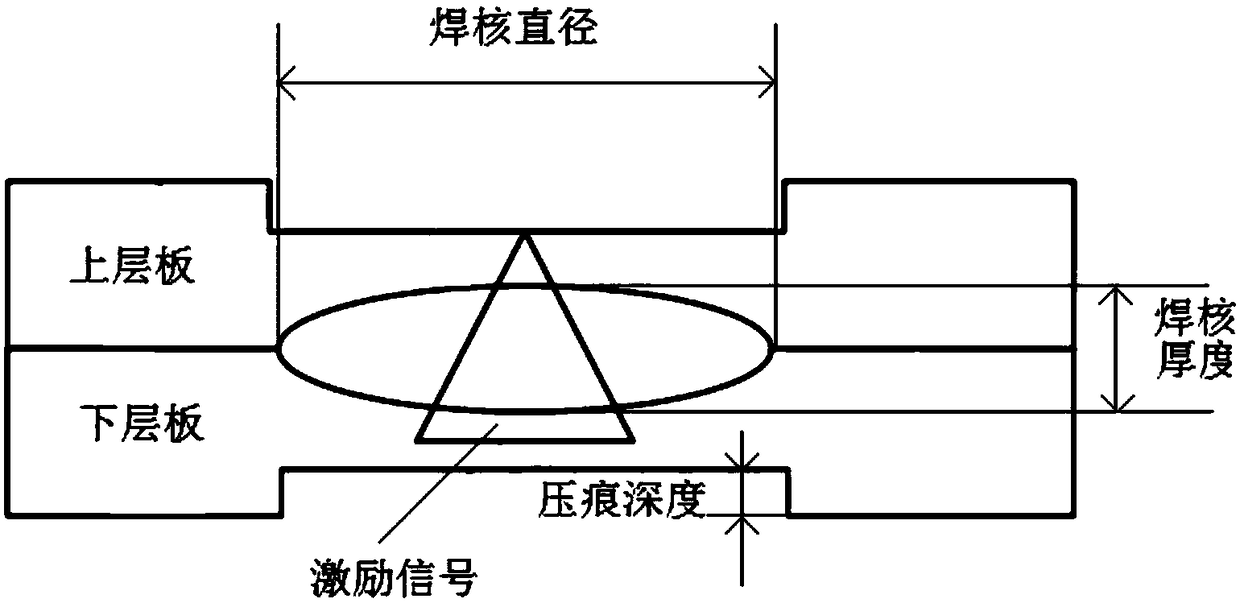

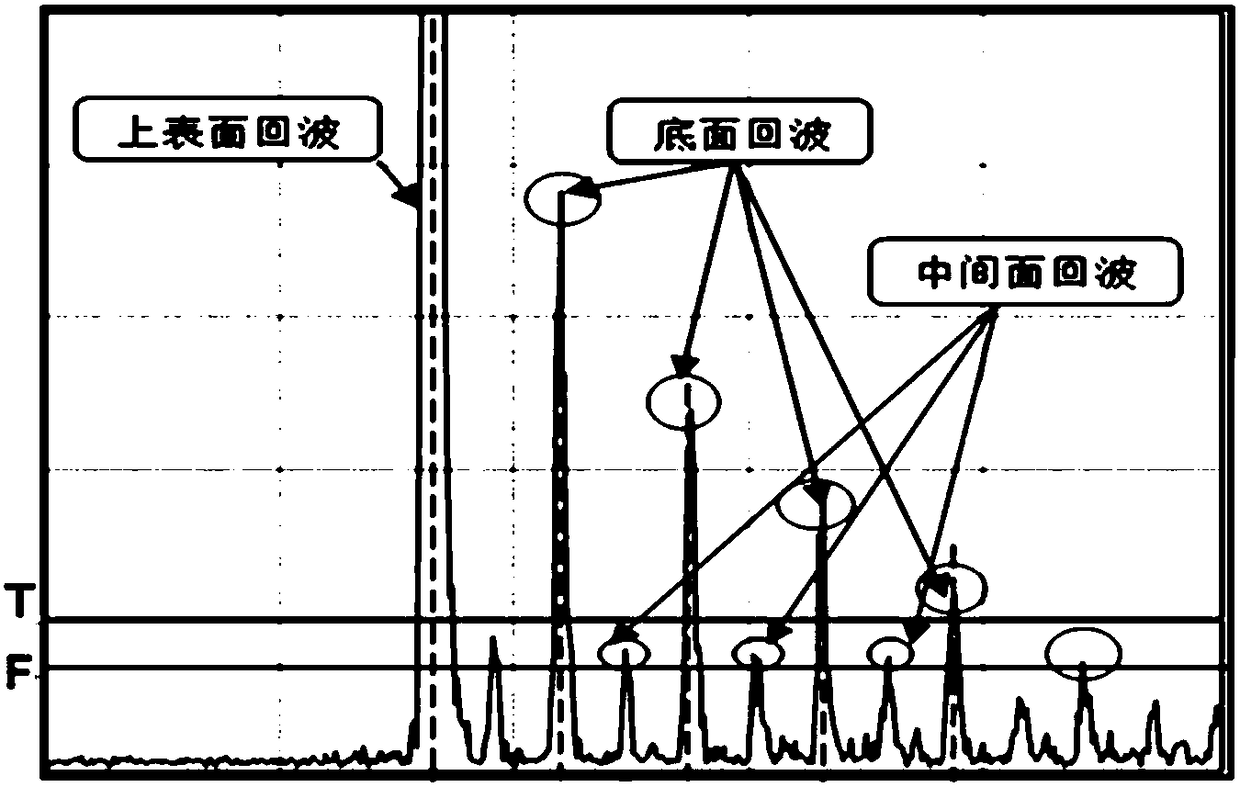

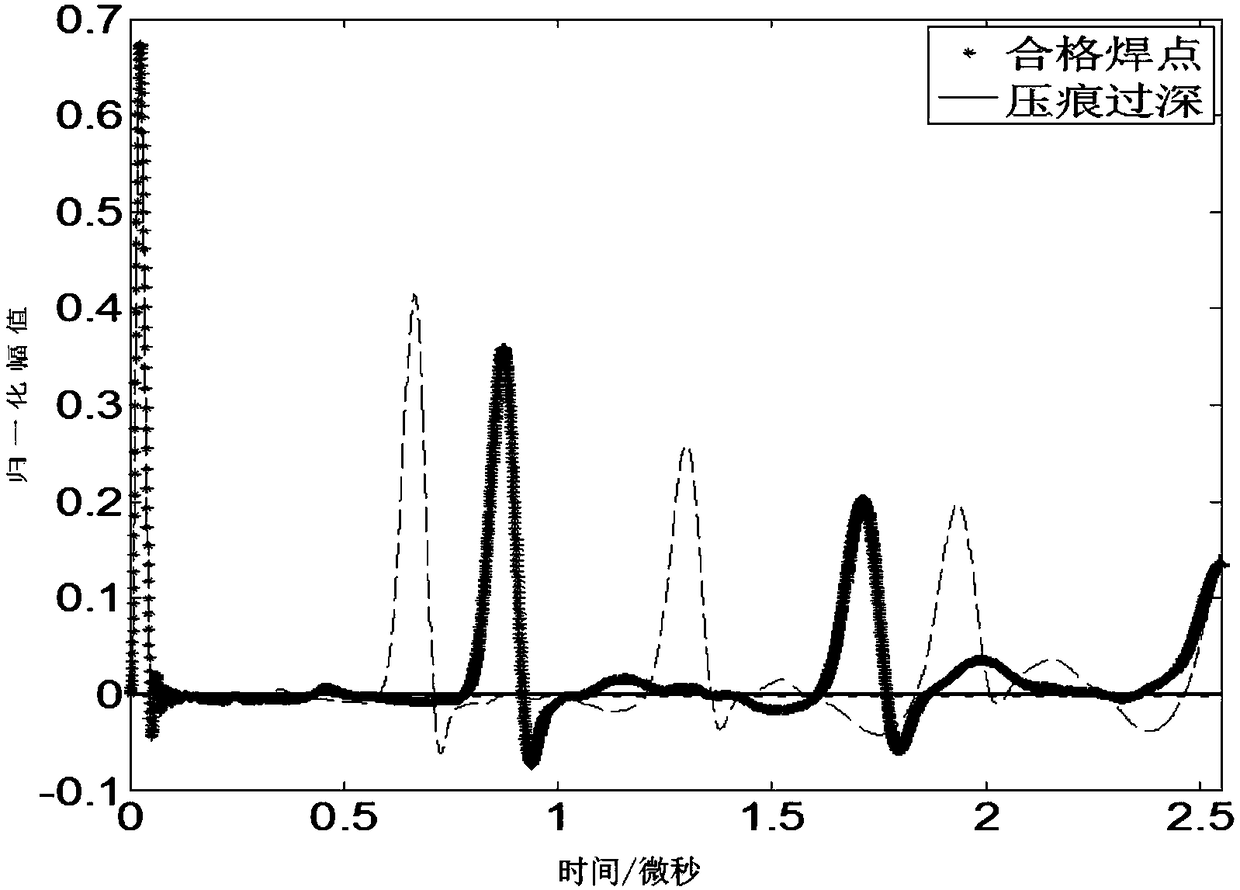

[0031] Attached below Figure 1~4 The present invention is described in further detail.

[0032] A method for establishing a solder joint quality inspection standard in an embodiment of the present invention includes:

[0033] Step 101, making solder joint samples;

[0034] The embodiment of the present invention adopts the method of combining actual detection and simulation experiment to obtain experimental data. Different from the prior art, the actual detection object of the embodiment of the present invention is the produced solder joint sample, rather than the real solder joint on the automobile body-in-white. The advantage of actual inspection of solder joint samples is that it is easier to obtain experimental data of solder joints with different thickness combinations and different nugget parameters, and the types of experimental data are much more comprehensive than those obtained by using actual solder joints.

[0035] Step 102, performing ultrasonic testing on eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com