A circuit board defect detection system and method on a production line

A defect detection and circuit board technology, applied in the field of automatic identification, can solve problems such as low reliability, low work efficiency, and inability to inspect circuit boards, and achieve the effect of ensuring reliability and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

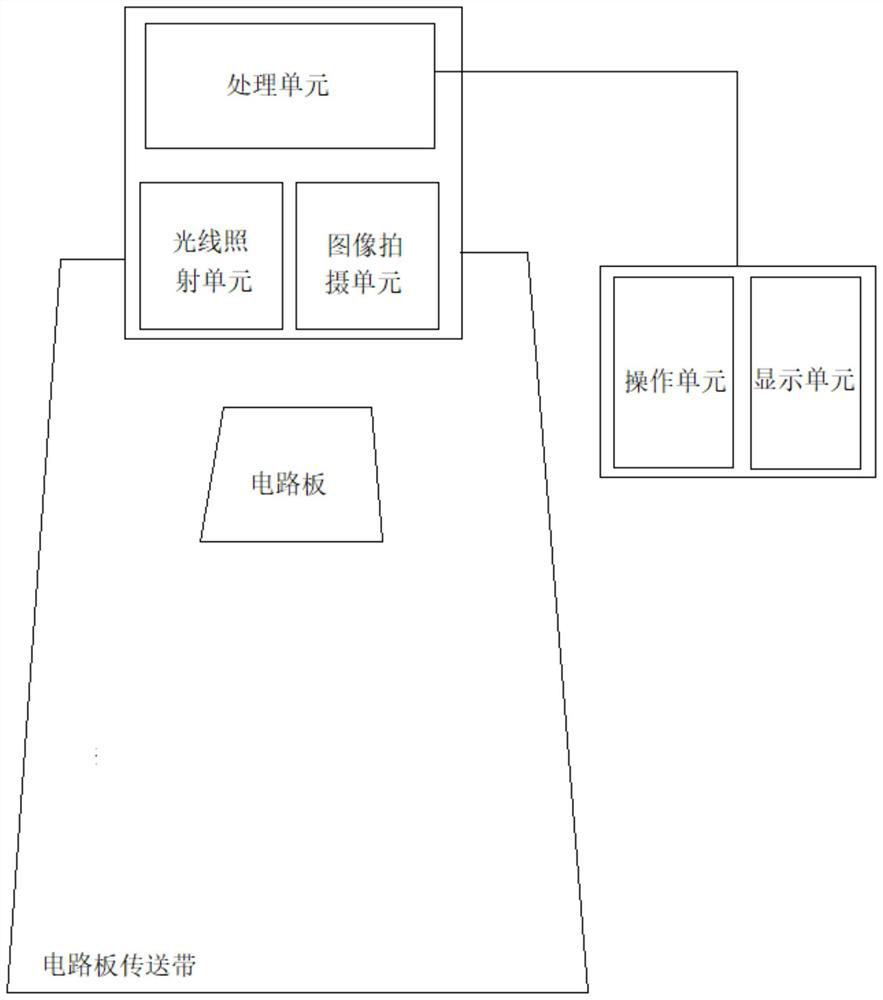

[0052] like figure 1 As shown, a circuit board defect detection system on a production line includes a light irradiation unit, an image capture unit, an operation unit, a processing unit, and a display unit; the processing unit is connected to the image capture unit, the operation unit, and the display unit respectively.

[0053] The light irradiation unit is installed above the circuit board conveyor belt. The light irradiation unit is used to project illumination light onto the circuit board conveyor belt. The image capture unit is installed above the circuit board conveyor belt. The image capture unit is used to capture the circuit board conveyor belt in real time from a top view angle Image information on the computer, and transmit the collected image information to the processing unit for image processing.

[0054] The operation unit is used to realize the switch control of the system and the control of template training, the processing unit is used to realize the functio...

Embodiment 2

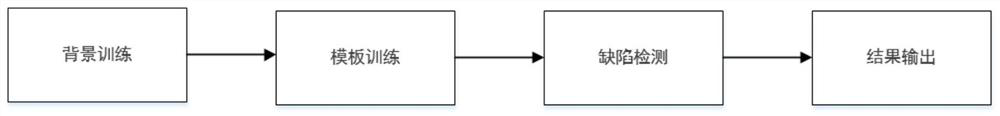

[0064] like figure 2 As shown, a circuit board defect detection method on a production line includes the above-mentioned circuit board defect detection system on a production line, and specifically includes the following steps:

[0065] A. After installing and fixing the detection equipment, click the background training button of the operation unit, and control the processing unit through the operation unit to perform background training;

[0066] B. Click the template training button of the operation unit, and control the processing unit through the operation unit to perform template training;

[0067] C. Carry out defect detection of the circuit board through the processing unit;

[0068] D. The processing unit outputs the detection result to the display unit for display.

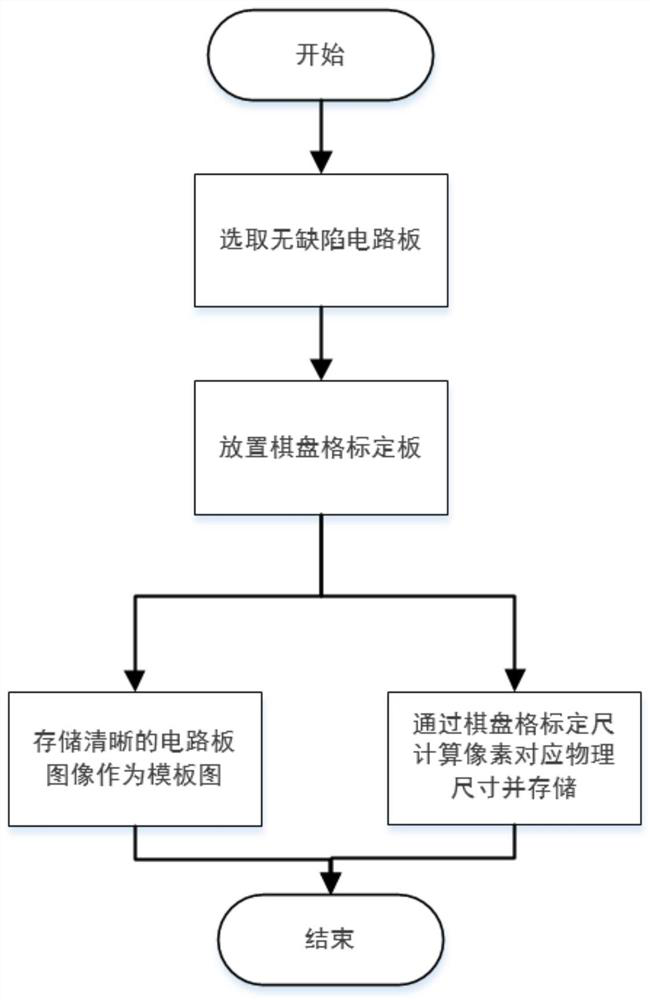

[0069] Specifically, Step A specifically includes the following steps:

[0070] A1. Send a control instruction to control the processing unit to perform background training through the operation unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com