Workpiece oil soaking dryer

A drying machine and oil-soaking technology, which is applied to coatings and devices for coating liquid on the surface, etc., can solve problems such as rust, large environmental pollution of anti-rust oil, and excessive anti-rust oil, so as to avoid environmental pollution, The effect of improving the drying effect of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

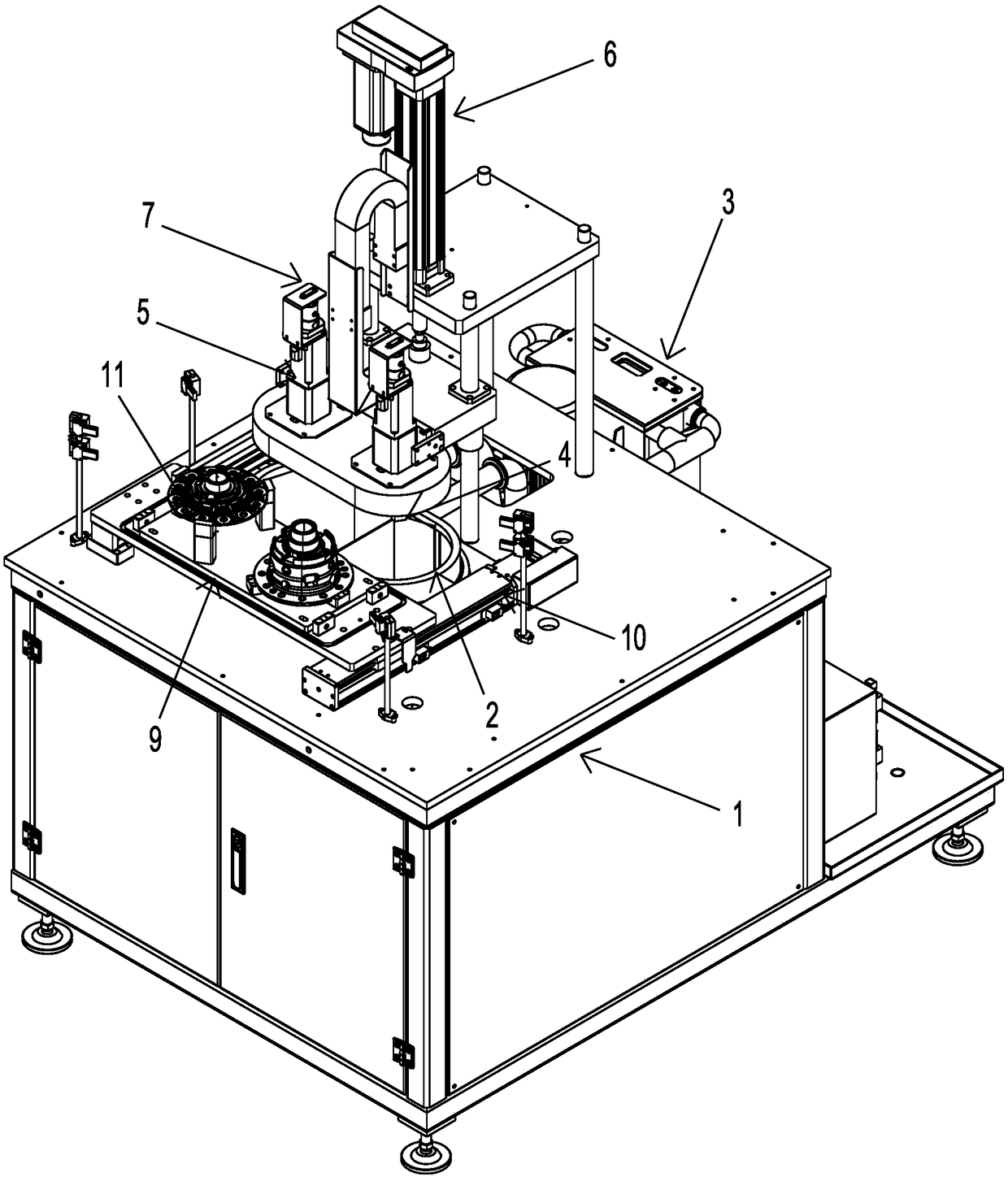

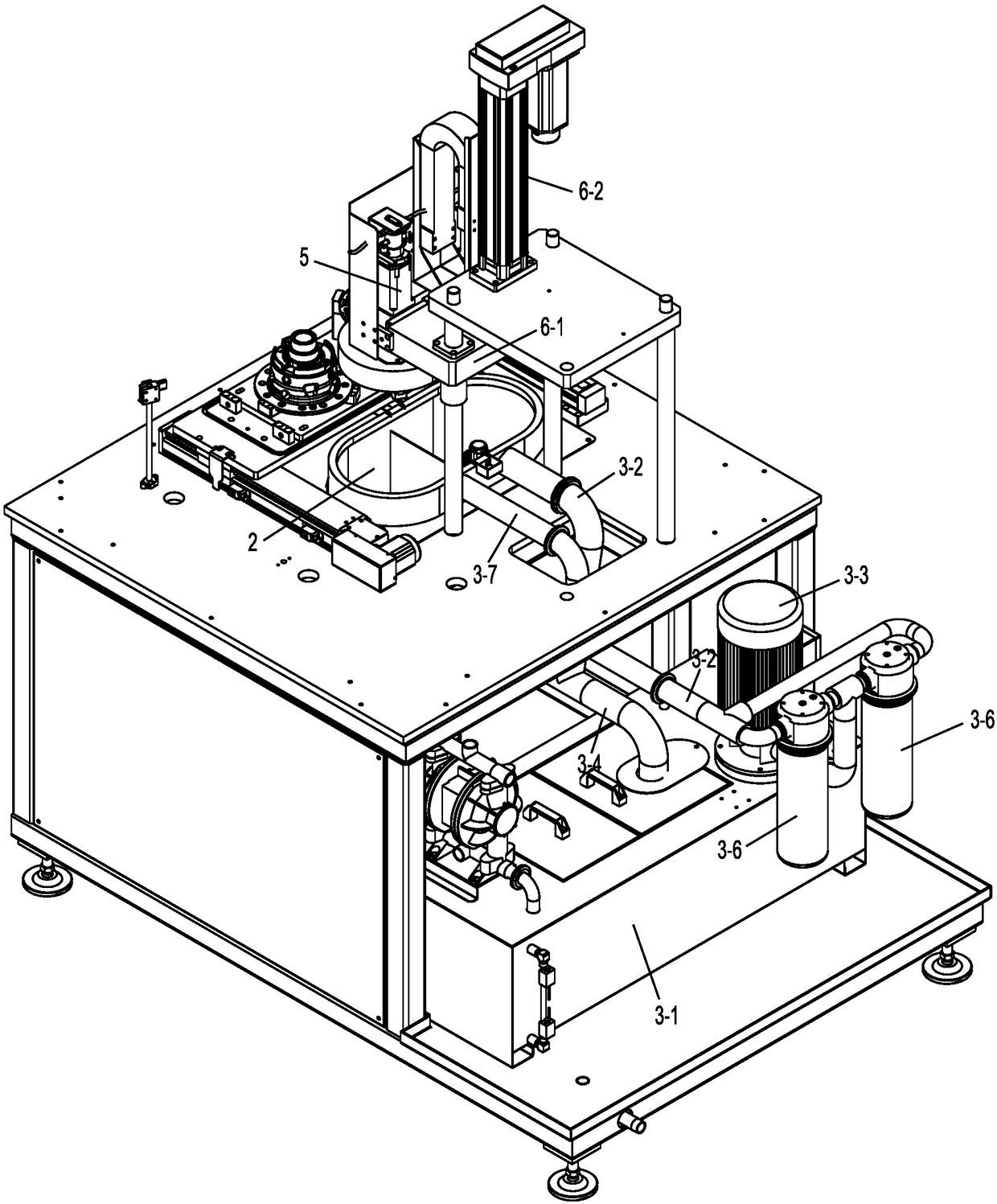

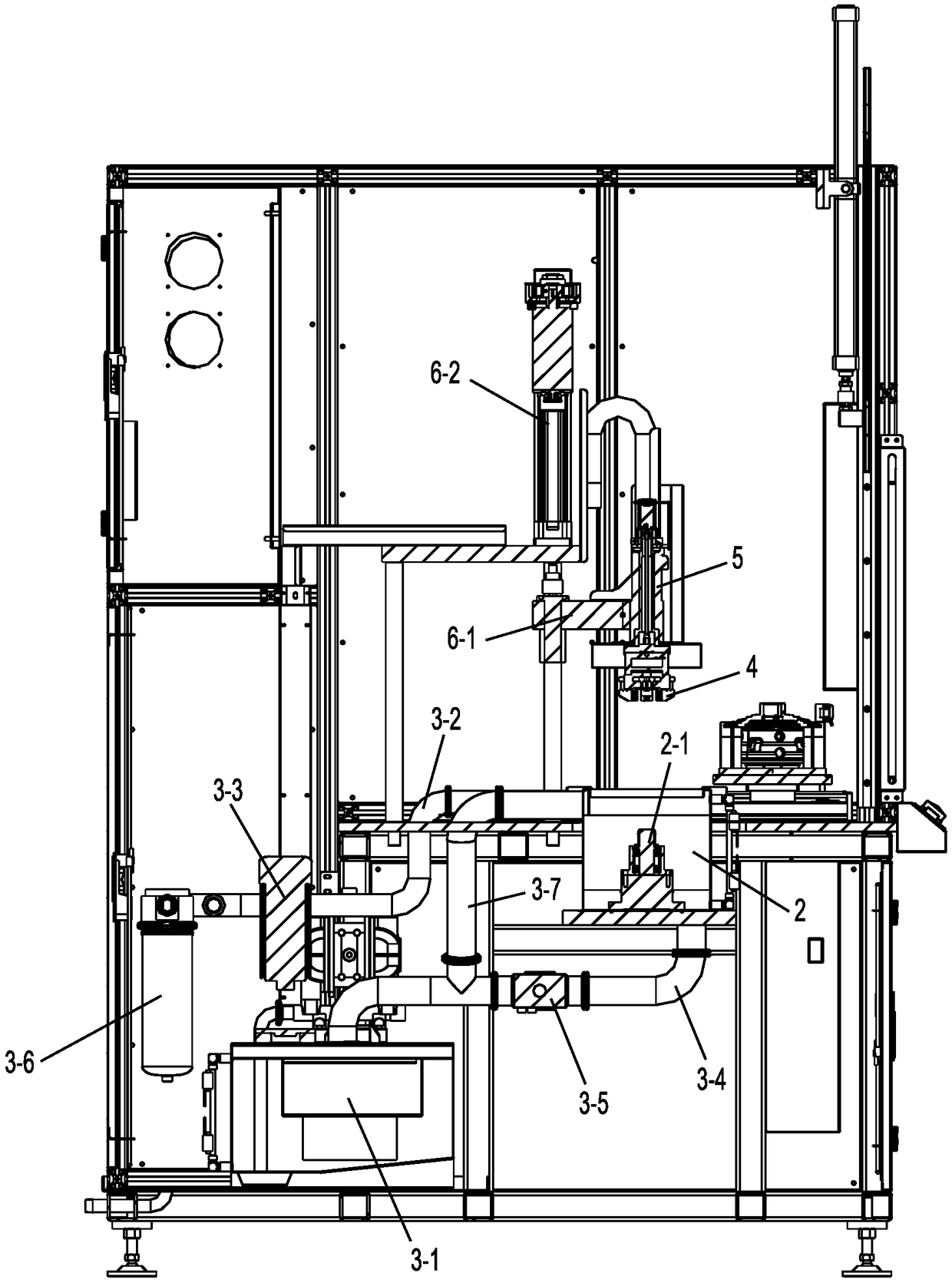

[0017] Such as Figures 1 to 6 Shown is a schematic diagram of an embodiment of a workpiece soaking oil drying machine provided by the present invention.

[0018] A workpiece oil soaking and drying machine, which includes a frame 1, an oil soaking mechanism arranged on the frame 1, and a grasping and rotating mechanism for putting workpieces into the oil soaking mechanism for soaking and drying.

[0019] The oil soaking mechanism includes an oil storage chamber 2 with an open upper end and an oil inlet and outlet control assembly 3 that injects antirust oil into the oil storage chamber 2 and pumps out the antirust oil after the workpiece is soaked.

[0020] The grasping and rotating mechanism includes a grasping component 4 , a rotary driving member 5 that drives the grasping component 4 to rotate, and a soaking driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com