Intelligent machine tool working state identification system based on signal fusion

A technology of working status and signal fusion, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of poor robustness and low accuracy, and achieve the level of reducing downtime, eliminating misjudgment, and improving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

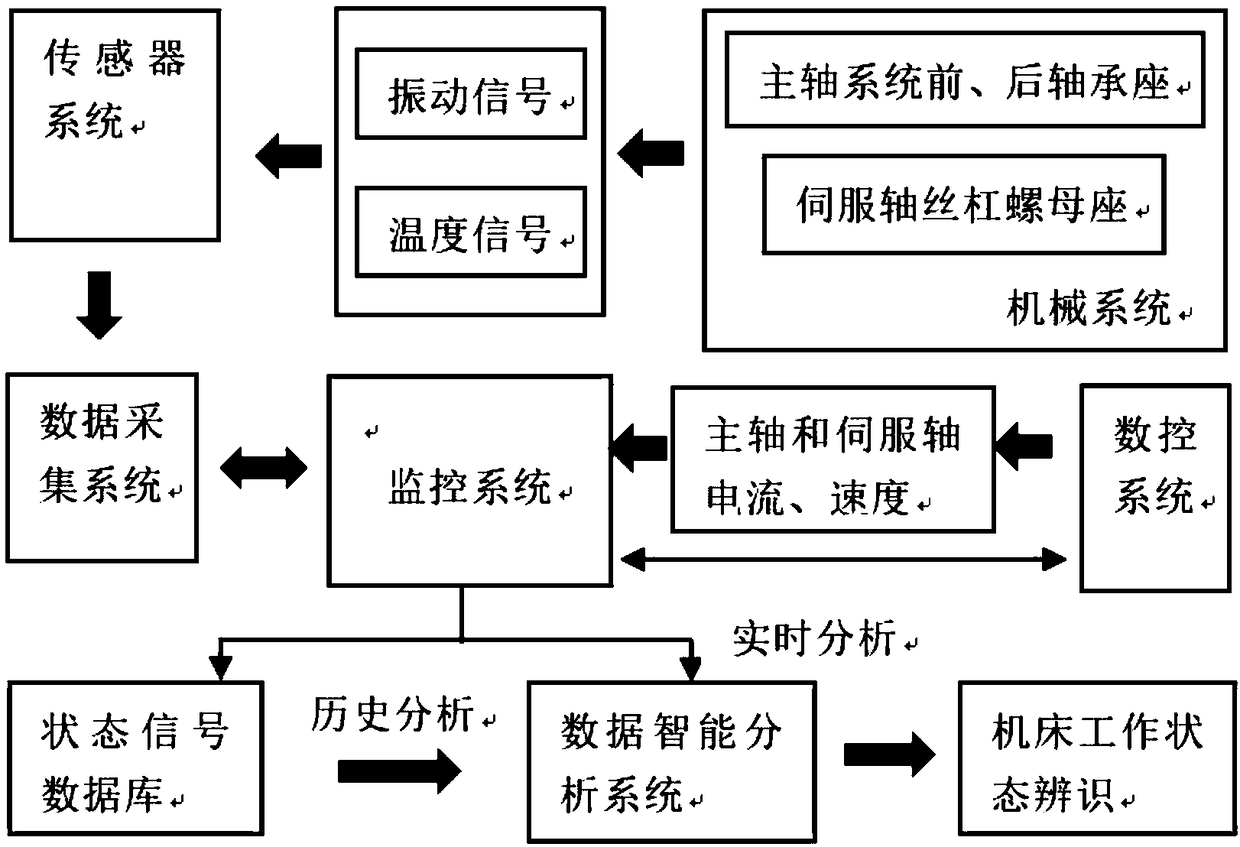

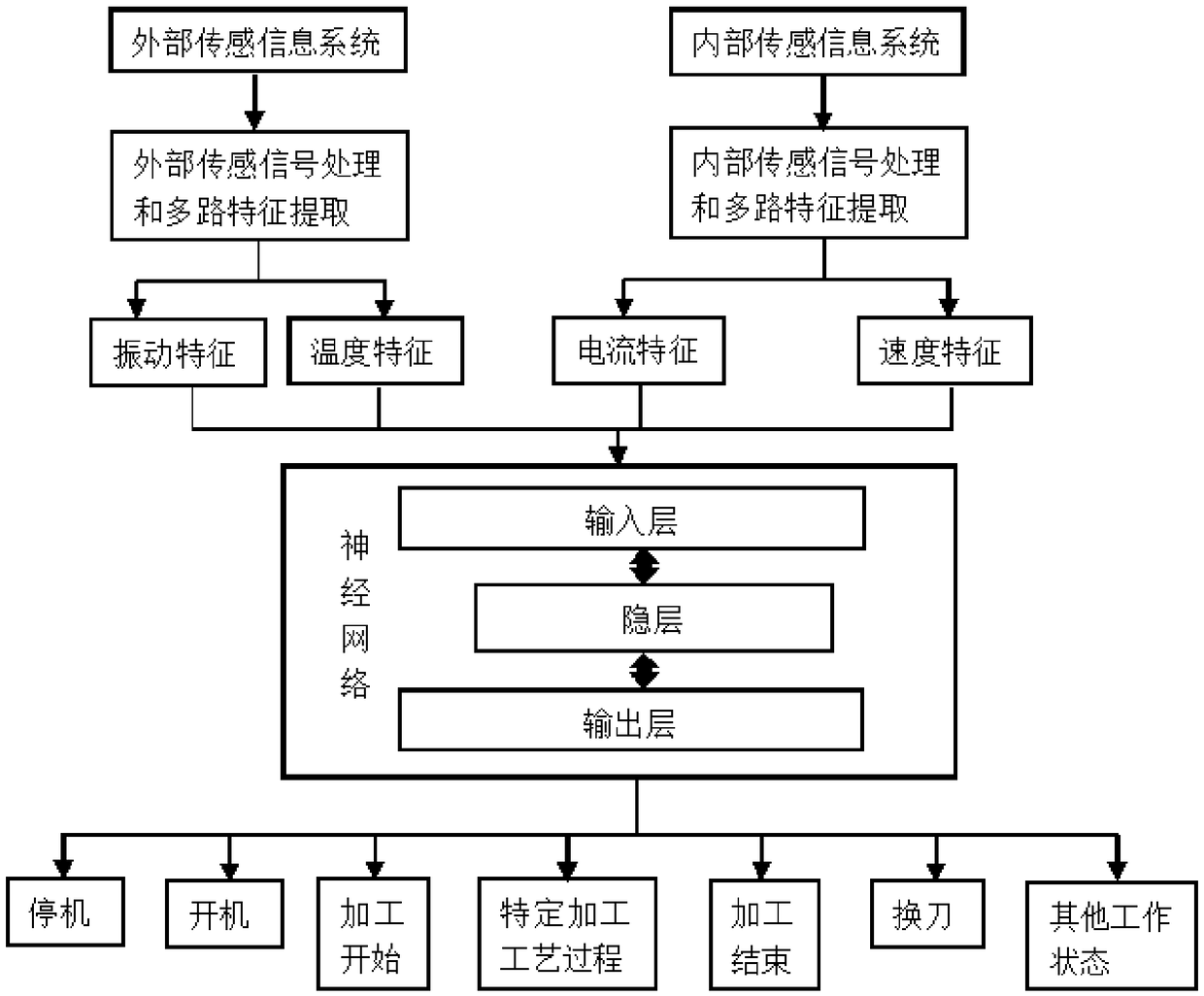

[0041] This embodiment provides a signal fusion-based intelligent identification system for the working state of a machine tool, including a sensor system (vibration signal sensor, temperature signal sensor, numerical control system), a data acquisition system, a monitoring system, a state signal database system, and an intelligent data analysis system , where: the sensor system is installed in the mechanical system part of the machine tool, the data acquisition system converts the vibration and temperature analog signals collected by the sensor system into digital signals, the monitoring system communicates with the sensor system's numerical control system and obtains the current of the spindle and servo axis And speed data, the signal data collected by the monitoring system control sensor is stored in the state signal database system or directly transmitted to the data intelligent analysis system for real-time analysis, and finally the intelligent identification of the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com