Equidistant automatic cutting device for wood

An automatic cutting device, equal-spacing technology, applied in wood processing appliances, forming/shaping machines, manufacturing tools, etc., can solve the problems of efficient equal-spacing cutting, low degree of automation, inability to realize wood, etc., and achieve improved stability and automation. The effect of high degree and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

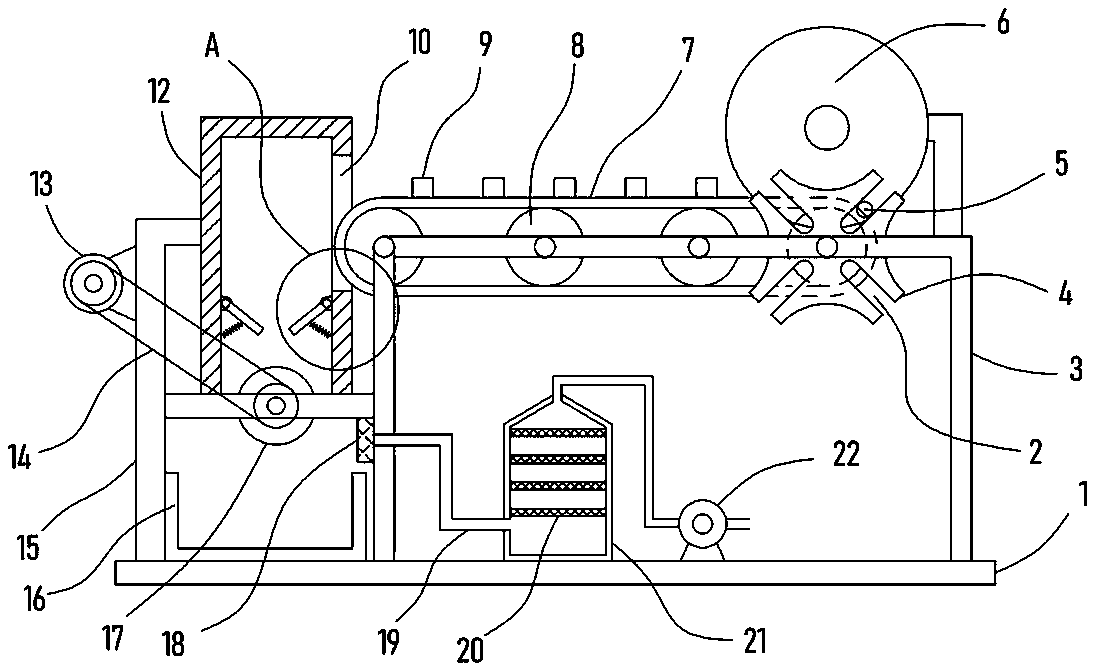

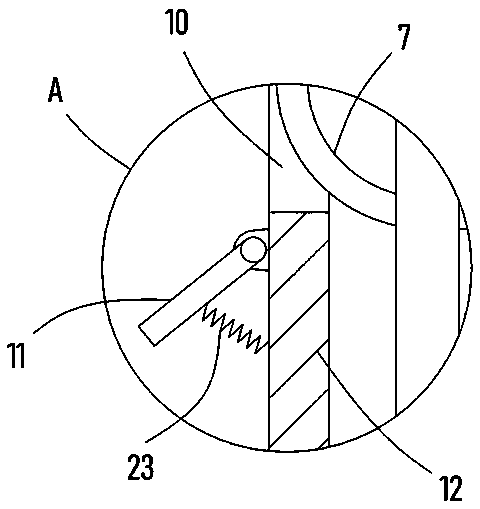

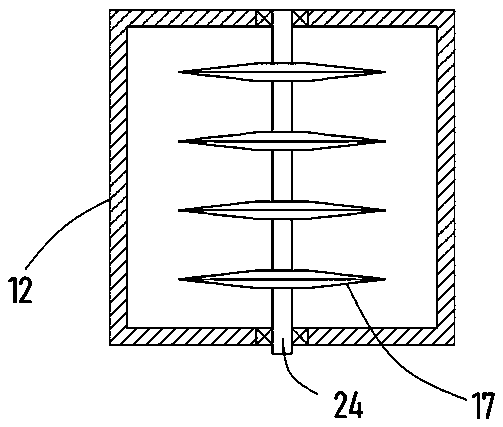

Embodiment 1

[0022] see Figure 1-4 , a kind of timber equidistant automatic cutting device, comprises bottom plate 1, and support frame 3 and fixed frame 15 are fixedly installed on the bottom plate 1, and guide frame 12 is vertically fixed on the described fixed frame 15, and the bottom of guide frame 12 is rotatably provided with Rotating shaft 24, several cutting blades 17 are fixed on the surface of rotating shaft 24 equidistantly, and the driving dial 6 is rotatably arranged on the support frame 3, and the front of the driving dial 6 is eccentrically fixed with a cylindrical pin shaft 5. Conveyor belt 7 is installed, and strip timber 9 is evenly placed on the conveyer belt 7.

[0023] The driving end of the conveyor belt 7 is coaxially fixed with a driven sheave 4, which is evenly provided with several radial grooves 2 adapted to the cylindrical pin shaft 5, and the driving dial 6 is drivingly connected with the driving device. The rotation of the dial 6 drives the cylindrical pin s...

Embodiment 2

[0028] On the basis of Embodiment 1, in addition, the dust filter box 21 and the exhaust fan 22 communicated with it through the pipeline are fixedly installed on the base plate 1, and the gas collection cover communicated with the dust filter box 21 through the dust guide pipe 19 is fixed on the fixed frame 15 18. The gas collecting hood 18 is located above the collection tank 16.

[0029] Further, several filter screens 20 are fixed horizontally at equal intervals in the dust filter box 21 , the connection between the dust guide pipe 19 and the dust filter box 21 is located below the filter screen 20 , and the connection between the fan 22 and the dust filter box 21 is located at the top of the dust filter box 21 .

[0030] In the process that the cutting blade 17 cuts the bar-shaped timber 9, certain dust will be produced, which will directly cause dust pollution to the surrounding air. The air below the frame 12 carries the dust through the air collecting hood 18 and gathe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com