Main chain azobenzene type organic porous polymer material and preparation method thereof

A technology of porous polymer and azobenzene, which is applied in separation methods, chemical instruments and methods, water pollutants, etc., can solve problems such as the need to improve the preparation efficiency, and achieve the effects of good dispersibility, simple preparation and large pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

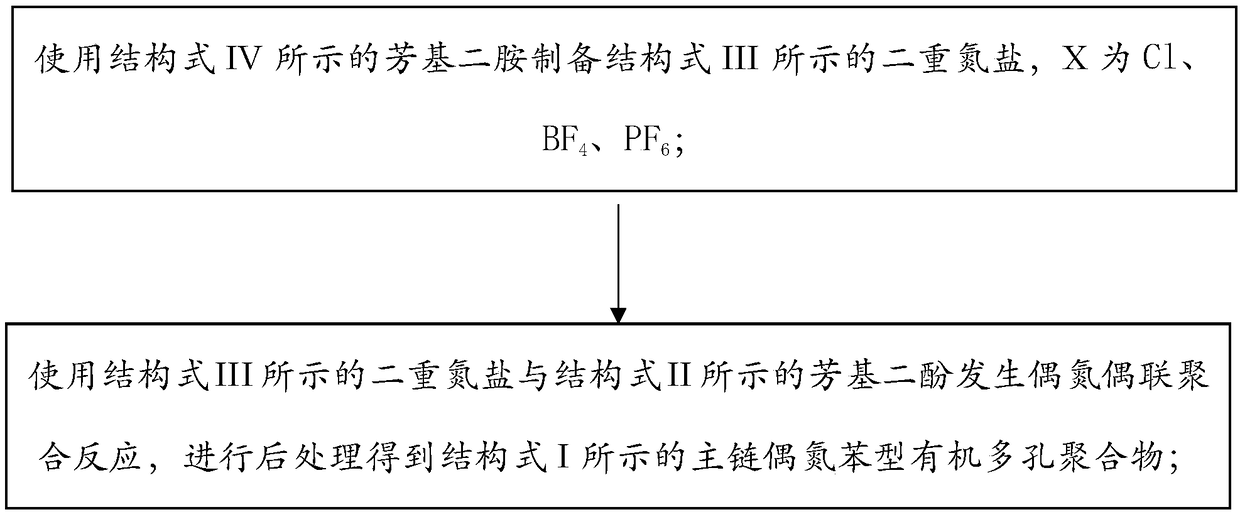

[0058] refer to figure 1 , which shows a flowchart of an embodiment of a method for preparing a main chain azobenzene-type organic porous polymer material of the present invention, which may specifically include:

[0059] Step 101, using the aryldiamine shown in the structural formula IV to prepare the diazonium salt shown in the structural formula III, X is Cl, BF 4 、PF 6 ;

[0060] Step 102, use the diazonium salt shown in the structural formula III to undergo an azo coupling polymerization reaction with the aryl diphenol shown in the structural formula II, and perform post-processing to obtain the main chain azobenzene organic compound shown in the structural formula I porous polymer material.

[0061]

[0062] In the embodiment of the present invention, X in the diazonia salt is Cl, BF 4 、PF 6 , the three-dimensional structure of the aryl diamine shown in the structural formula IV is a rigid twisted configuration.

[0063] In the embodiment of the present inventio...

Embodiment 1

[0089] A main chain azobenzene type organic porous polymer material, the structural formula is as follows:

[0090]

[0091] A kind of preparation method of main chain azobenzene type organic porous polymer material of the present invention, the steps are as follows:

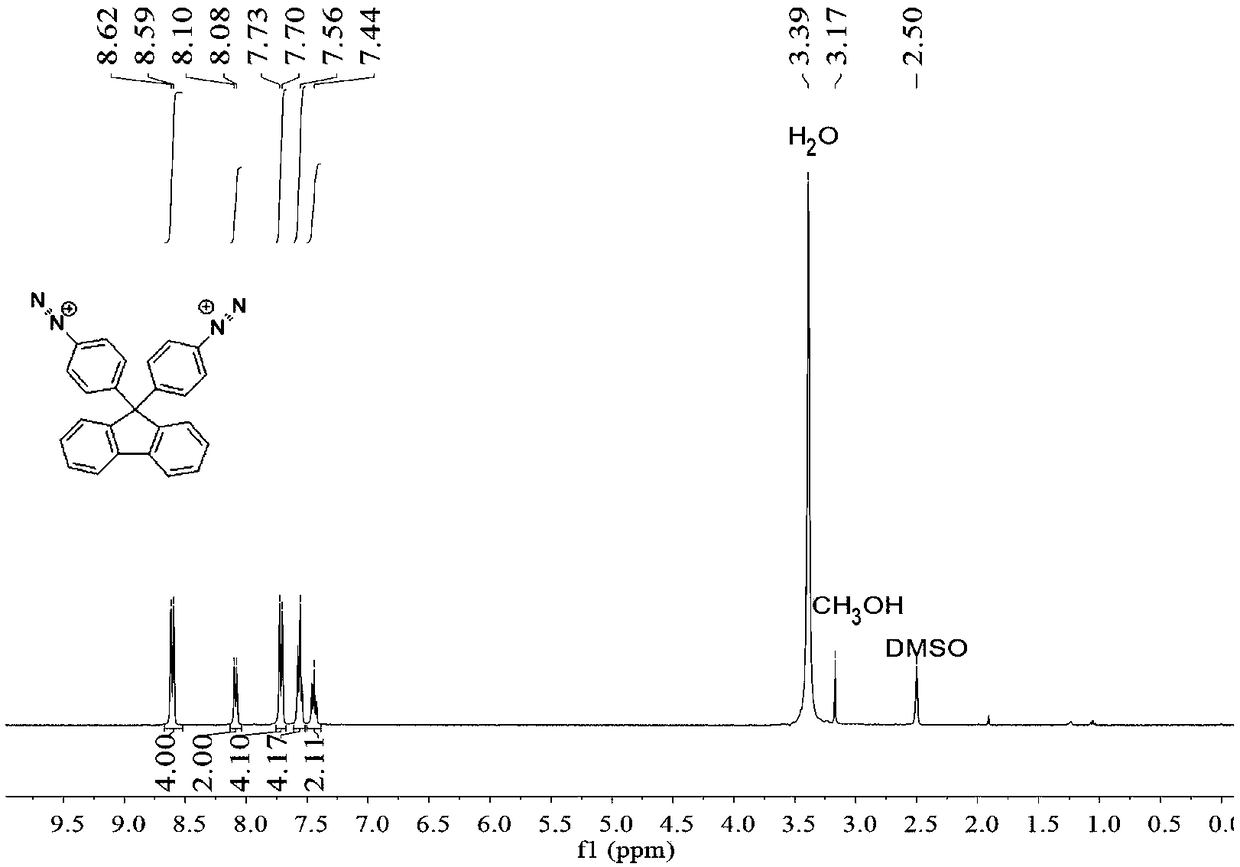

[0092] Step 1: Preparation of 9,9'-bis(4-phenyldiazotetrafluoroborate)fluorene.

[0093] In an ice-water bath, disperse 9,9'-bis(4-aminophenyl)fluorene (3.48g, 10mmol, 1eq) in 250mL of deionized water, and add HBF to it after the dispersion is uniform 4 (15.35mL, 100mmol, 10eq), stirred for 5min to completely dissolve 9,9'-bis(4-aminophenyl)fluorene. Then pre-cooled 10mL sodium nitrite aqueous solution (1.415g, 20.5mmol, 2.05eq) in ice water was added dropwise to the reaction system at a speed of 3 seconds / drop, and after reacting for 20min, the solid product was obtained by suction filtration. The solid was washed with deionized water and freeze-dried to obtain 4.02 g of solid (90% yield).

[0094] The em...

Embodiment 2

[0119] A main chain azobenzene type organic porous polymer material, the structural formula is as follows:

[0120]

[0121] A preparation method of a main chain azobenzene type organic porous polymer material, the specific steps are as follows:

[0122] Step 1: Preparation of 9,9'-bis(4-phenyldiazonium hydrochloride)fluorene.

[0123] In an ice-water bath, disperse 9,9'-bis(4-aminophenyl)fluorene (0.348g, 1mmol, 1eq) in 100mL of deionized water, and add HCl (0.667mL, 8mmol, 8eq ), and stirred for 5 minutes to completely dissolve 9,9'-bis(4-aminophenyl)fluorene. Then 10mL of potassium nitrite aqueous solution (0.172g, 2.05mmol, 0.205eq) pre-cooled in ice water was added dropwise to the reaction system at a rate of 3 seconds / drop, and after 25min of reaction, 9,9'-bis(4- phenyldiazonium hydrochloride) fluorene solution.

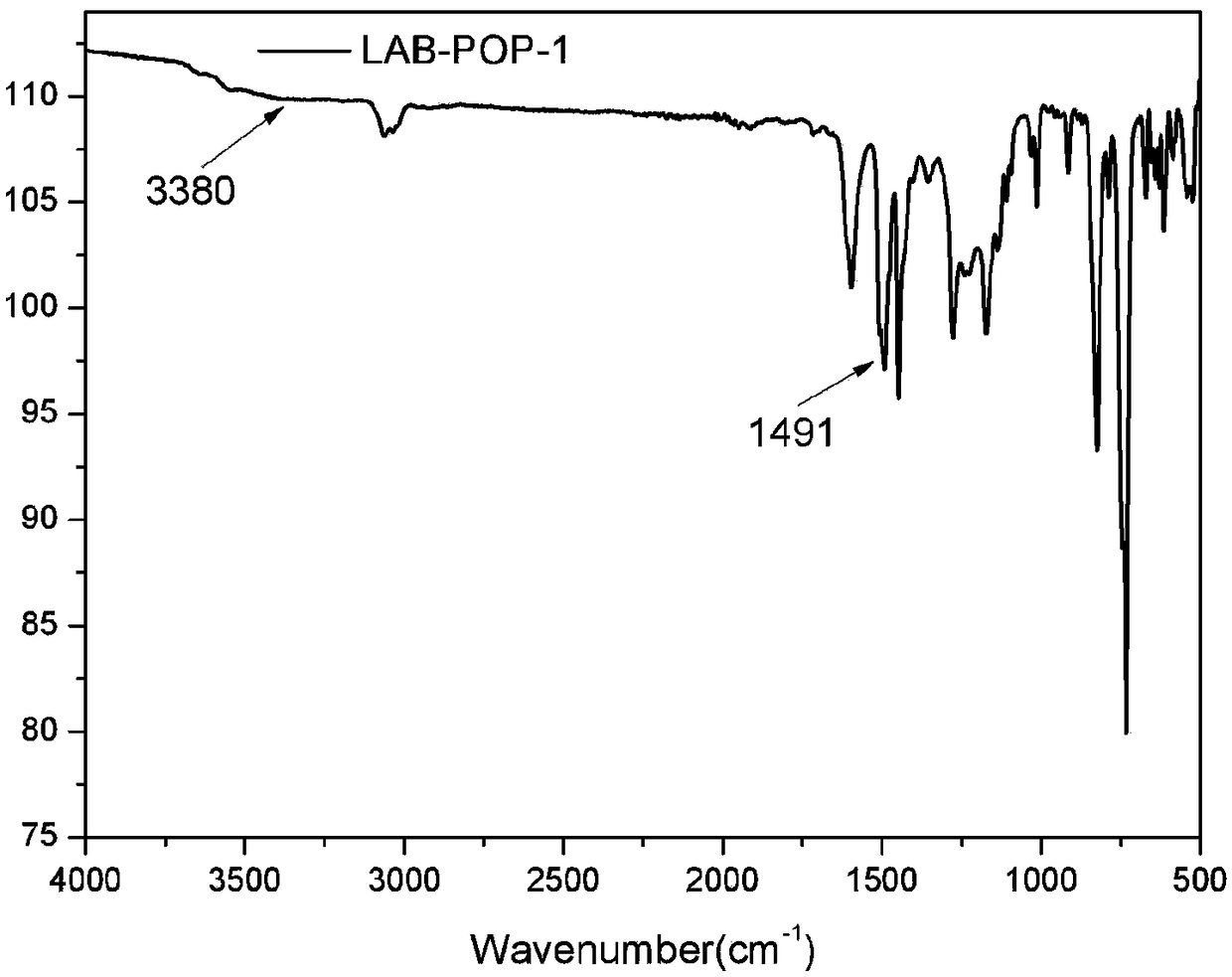

[0124] Step 2: Preparation of main chain azobenzene type organic porous polymer LAB-POP-2.

[0125] Under an ice-water bath, adjust the pH value of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com