Prefabricated assembly type composite slab suspension supporting structure and composite slab construction method thereof

A support structure, prefabricated assembly technology, applied in the direction of formwork/formwork/work frame, floor slab, building components, etc., can solve the problems of little improvement of the process and low construction efficiency, so as to reduce the difficulty of safety management, improve the construction efficiency, Improve the effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

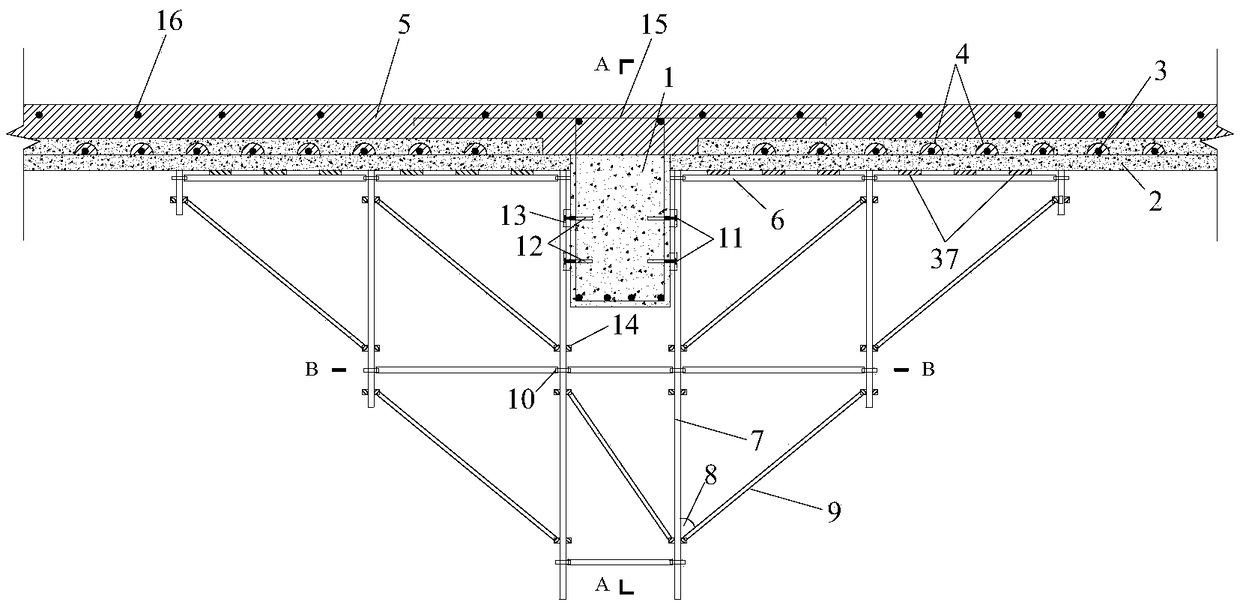

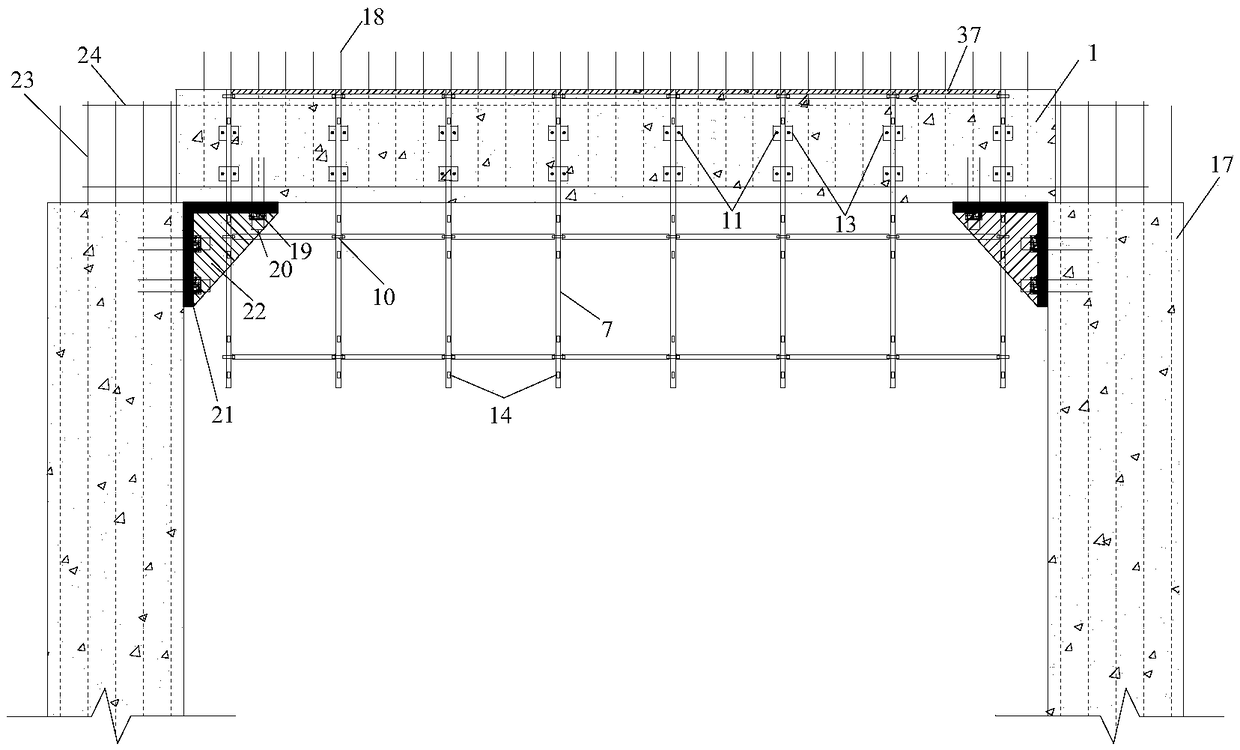

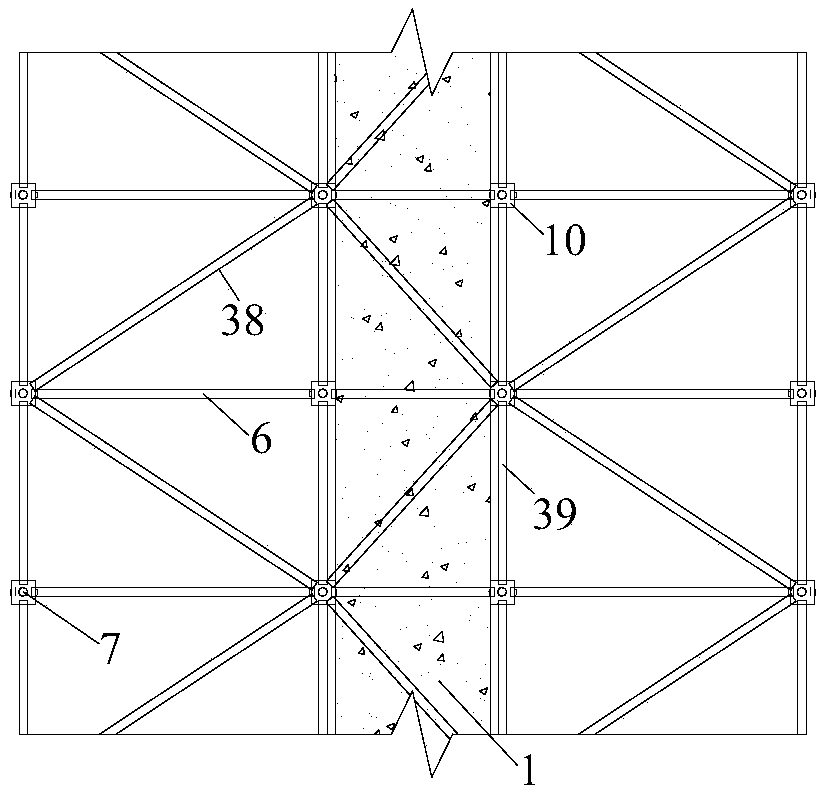

[0050] In order to deepen the understanding of the present invention, reference will be made to Figure 1 to Figure 10 , the embodiments of the present invention are described in detail, the following embodiments are implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

[0051] combined with Figure 1~3 As shown, a prefabricated assembled laminated slab suspension support structure related to the present invention includes a prefabricated beam 1 and a support system, and the two ends of the prefabricated beam 1 are fixed between two prefabricated concrete columns 17 through corner brackets 21 of. The support system is composed of a support vertical bar 7, a support cross bar 6, a support slant bar 9, a horizontal slant bar 38 and a horizontal connecting rod 39 connected to each other through a square buckle 10 and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com