A method and a device for calculating fracture conductivity value of a horizontal well to be fractured

A conductivity and horizontal well technology, applied in the field of horizontal well fracturing, can solve problems such as large error in fracture conductivity value and inappropriate fracturing point design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

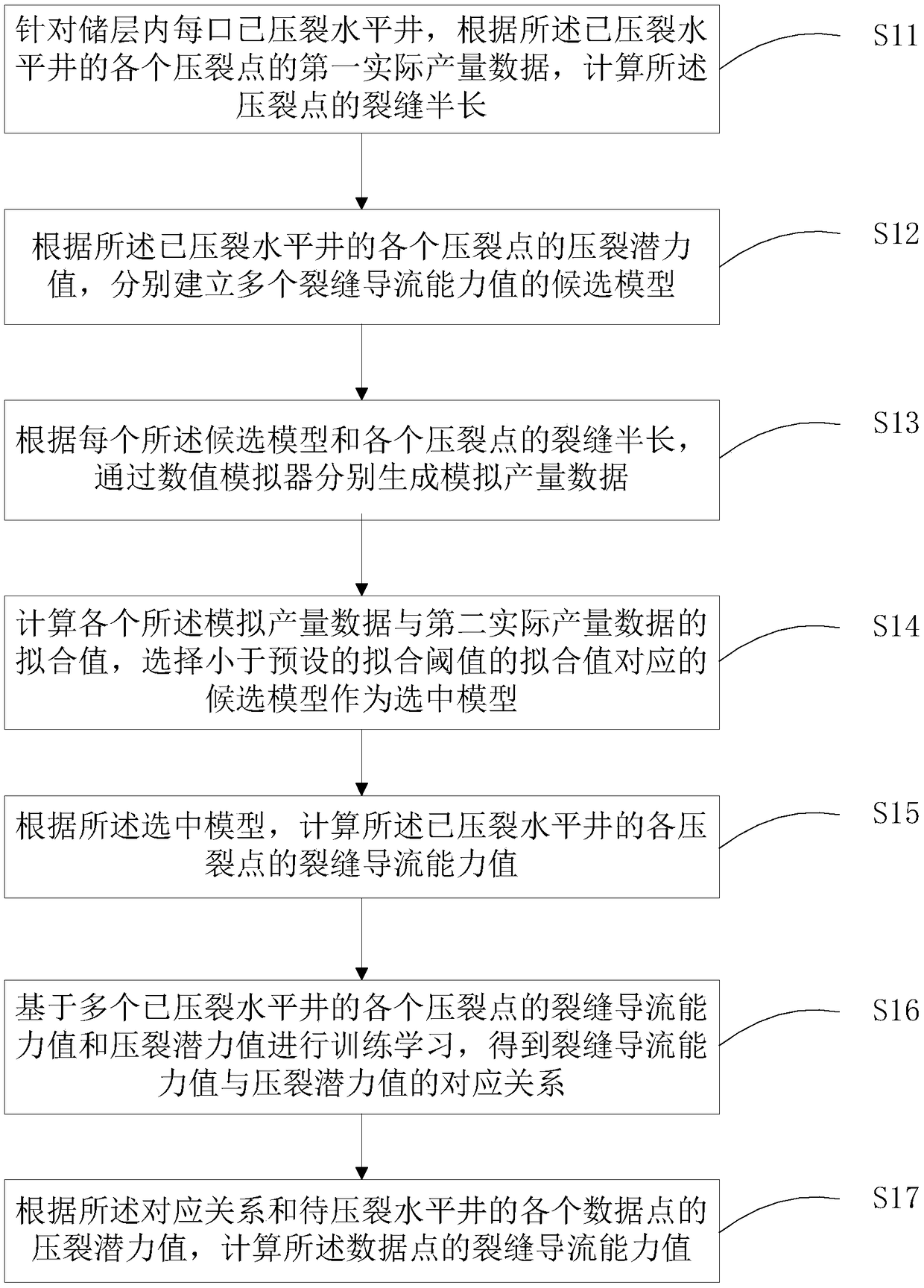

[0108] Embodiment 1 of the present invention provides a method for calculating the fracture conductivity value of a horizontal well to be fractured, the process of which is as follows figure 1 shown, including the following steps:

[0109] Step S11: For each fractured horizontal well in the reservoir, according to the first actual production data of each fracture point of the fractured horizontal well, calculate the half-length of the fracture at the fracture point.

[0110] Wherein, the fractured horizontal well refers to a horizontal well that has been fractured and put into production.

[0111] Wherein, the first actual production data includes the oil production at each time step of the fracturing point.

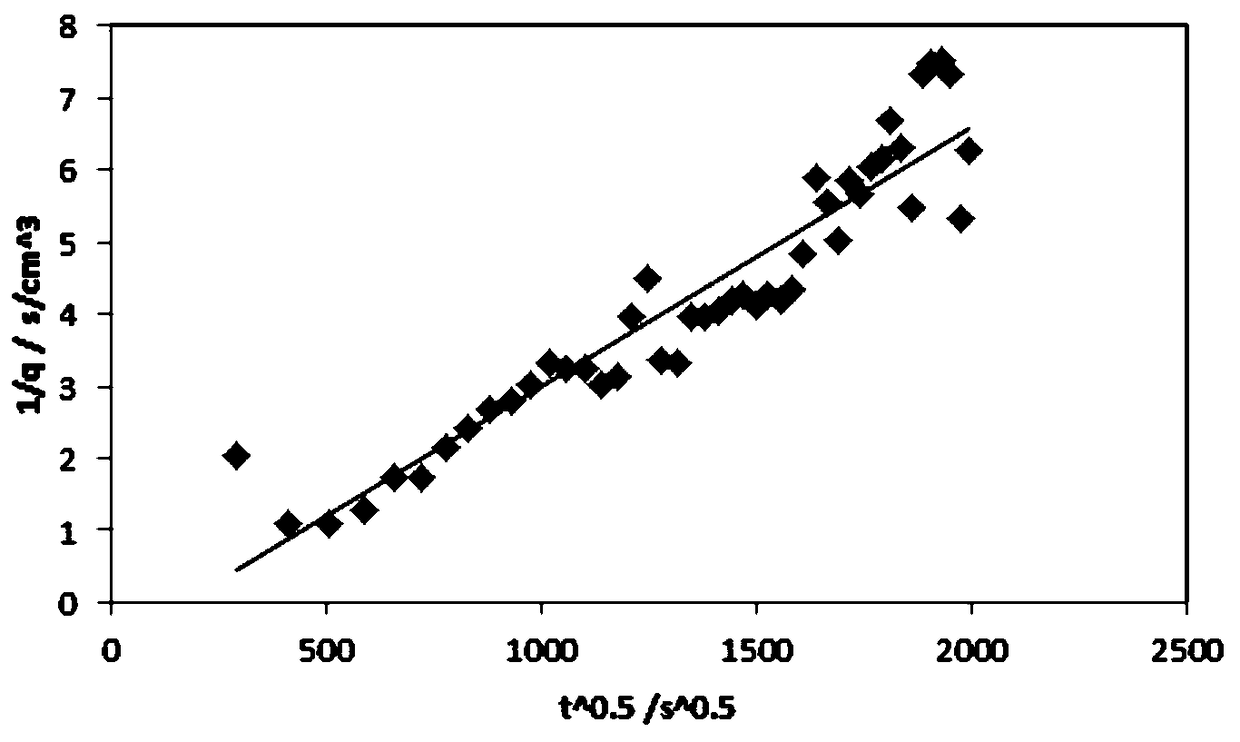

[0112] Calculating the half-length of the fracture at each fracturing point, specifically, it may be to fit the root of the time corresponding to each time step in the first actual production data as the abscissa and the time step corresponding to the first actual produ...

Embodiment 2

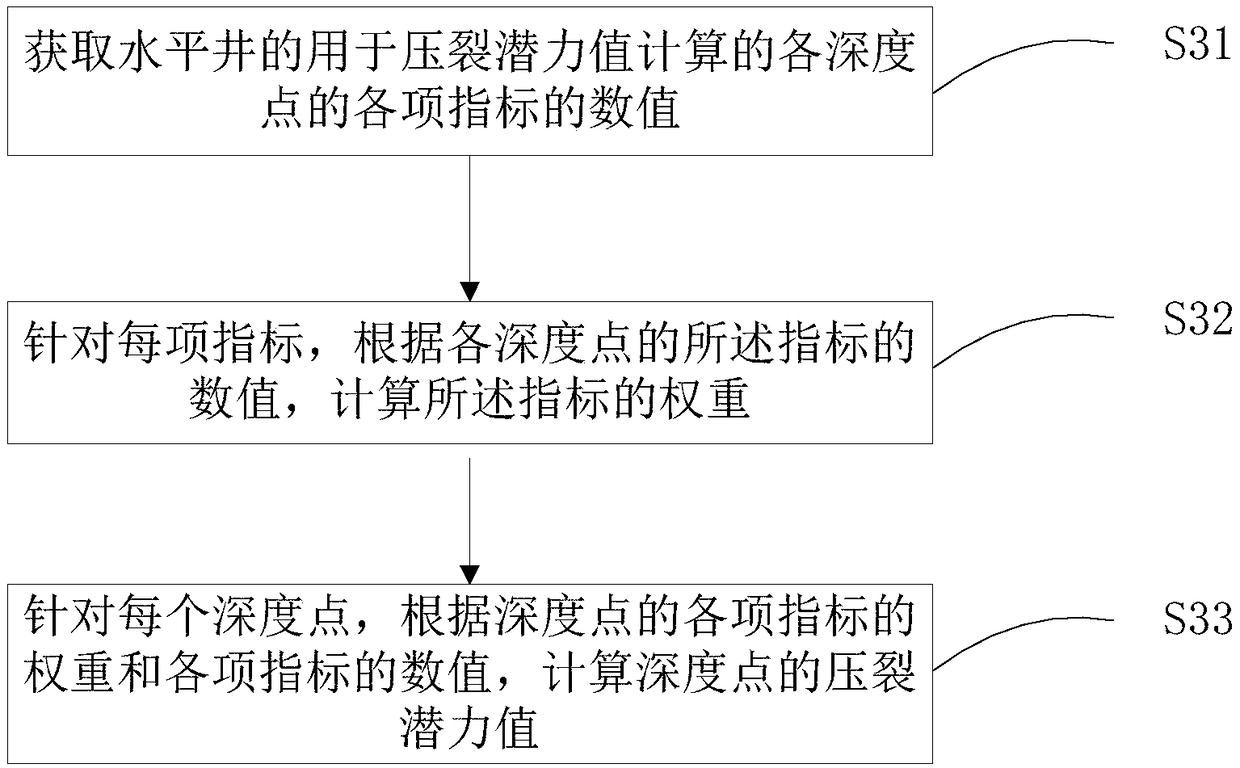

[0155] The calculation of the fracturing potential value of each fracturing point of the fractured horizontal well in step S12 of the above-mentioned embodiment 1, or the calculation of the fracturing potential value of each data point of the horizontal well to be fractured in step S17, can be specifically according to the embodiment of the present invention II provides a method for calculating the fracturing potential value of horizontal wells, and the process is as follows image 3 shown, including the following steps:

[0156] Step S31: Acquiring the values of various indicators at each depth point of the horizontal well used for the calculation of the fracturing potential value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com