Hinge type stator and circle forming method thereof

A hinged, stator technology, applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, electrical components, etc., can solve the problems of increasing labor costs, affecting the insulation performance of the motor, and poor comprehensive performance of the motor, etc. The circle method is simple, the material utilization rate is improved, and the winding layout is reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the embodiments and the accompanying drawings.

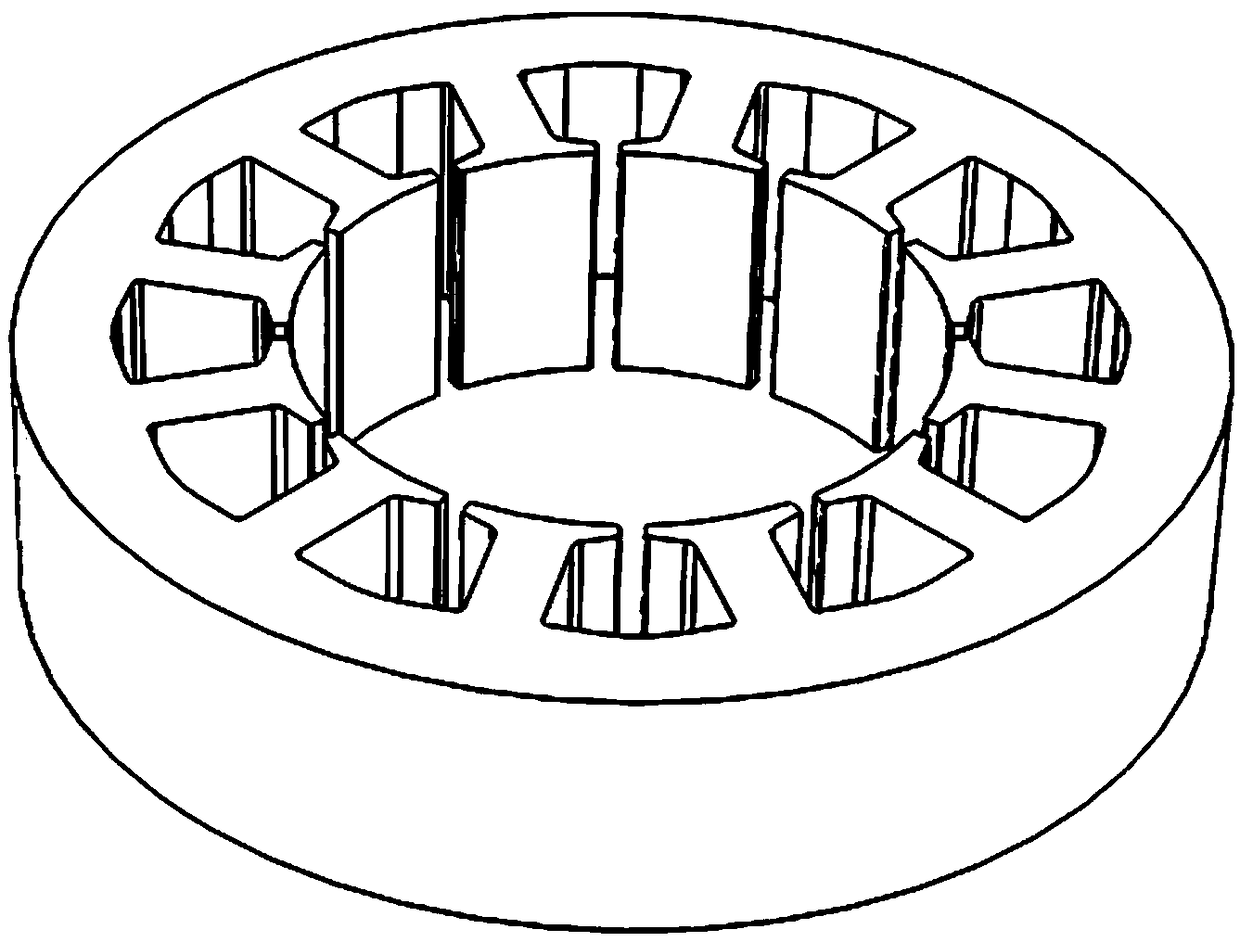

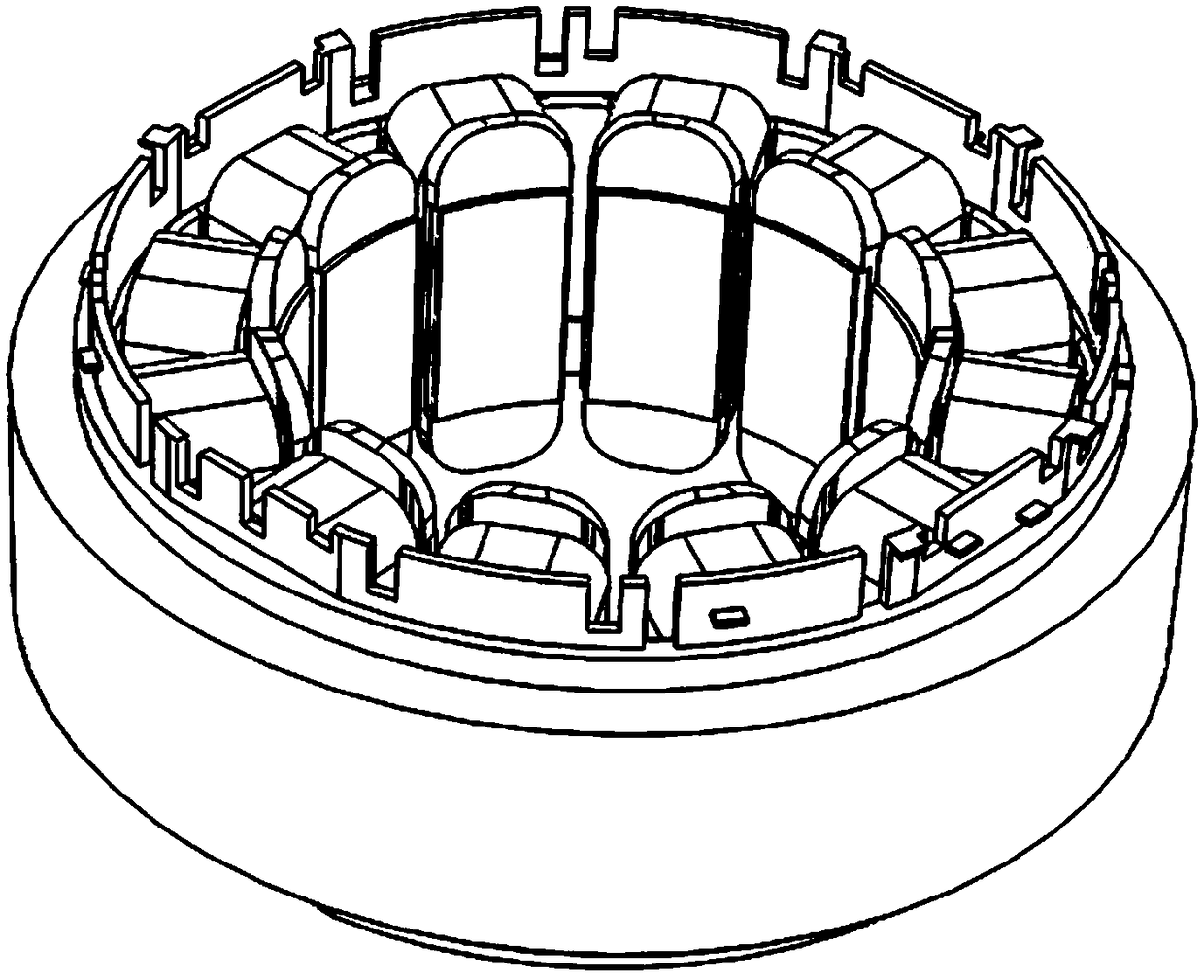

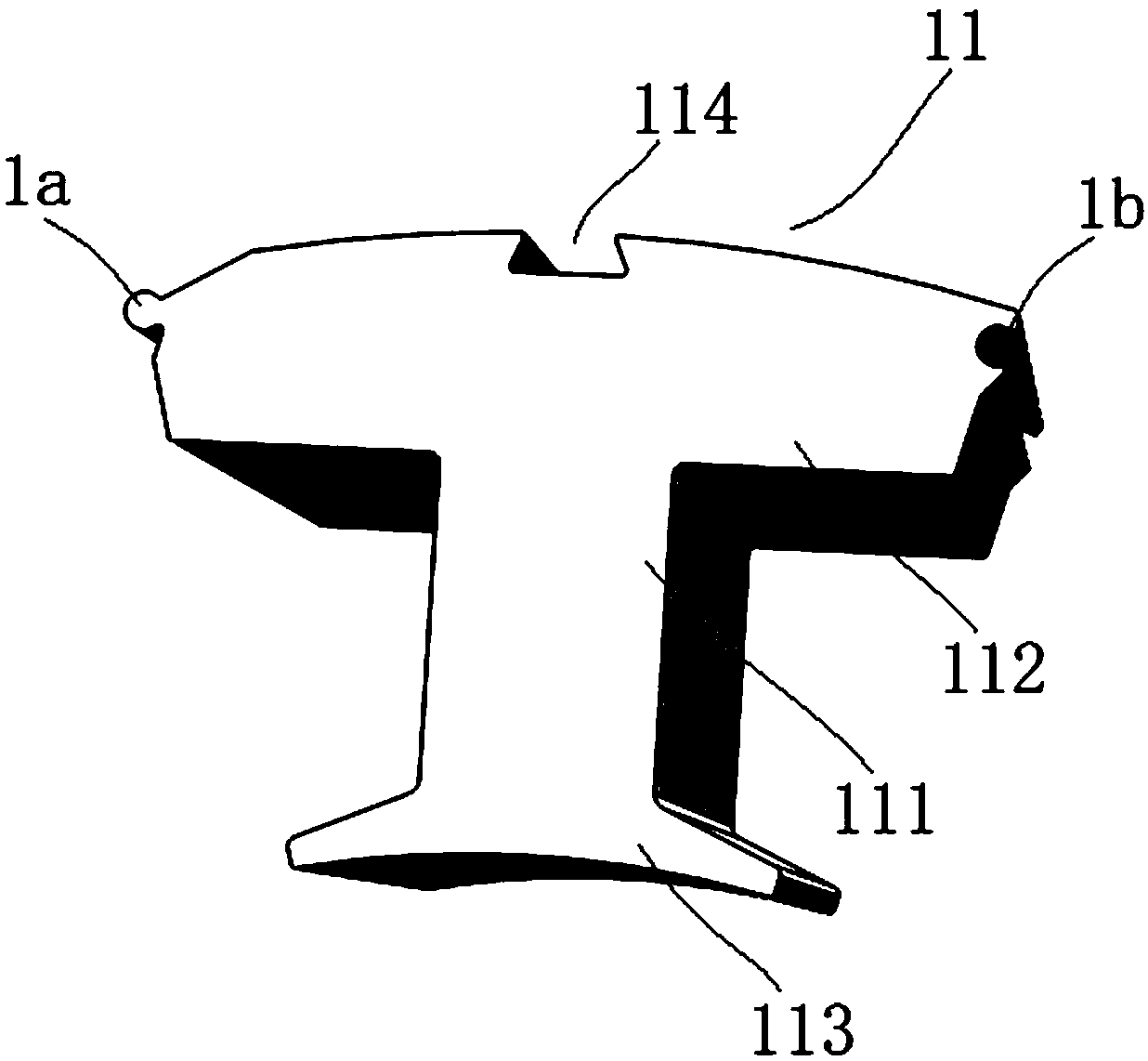

[0032] A hinged stator structure 100, such as Figure 7 As shown, it includes a stator core 10 and a stator coil 20, characterized in that the stator core 10 is composed of a plurality of stator core blocks 11 with grooves and flanges at both ends passing through the grooves and the The flanges are inserted and assembled, each of the stator core segments 11 is composed of stator teeth 111, stator yokes 112 and pole shoes 113, and the space between two adjacent stator core segments 11 The gap constitutes the stator slot 115, the stator coil 20 is wound on the stator tooth 111 through the stator slot 115, and the first and last stator core blocks 11 wound around the stator coil 20 are inserted into the flange through the groove. Combined, the hinged stator 100 is formed. The stator core segment 11 is divided into two types according to the shape of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com