Revolving speed observation method for induction machine

An induction motor and rotational speed technology, applied in the field of induction motor rotational speed observation, can solve problems such as low identification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

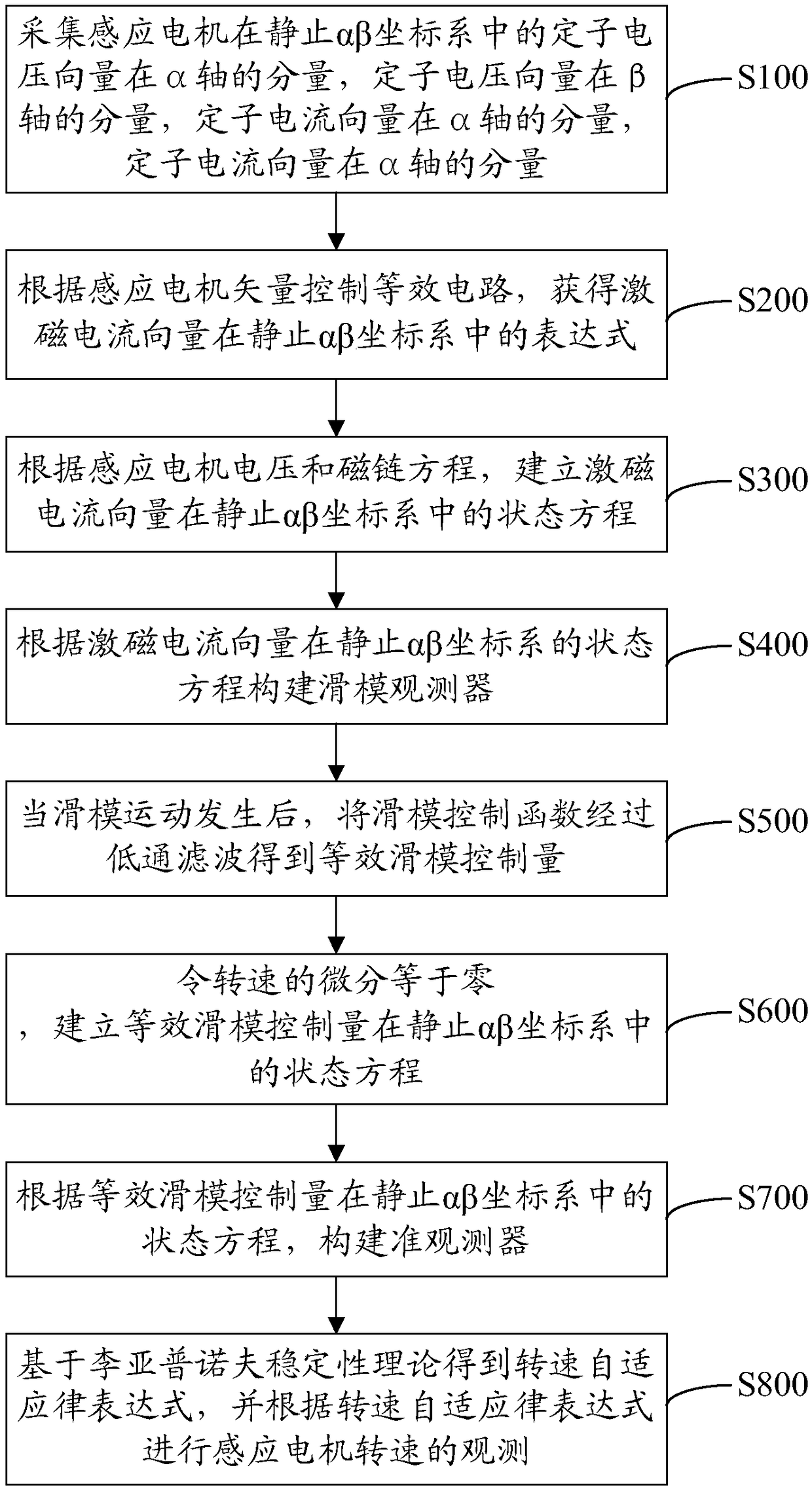

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

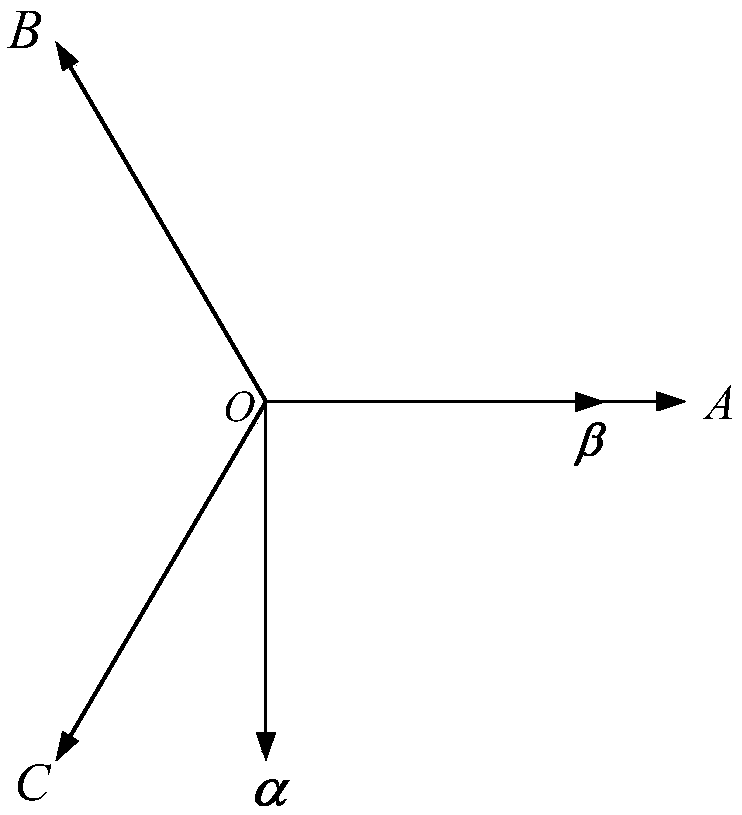

[0102] Further, in step S100, the stator current vector i of the induction motor in the stationary αβ coordinate system s Component i on the α axis sα , the stator current vector i s Component i on the β axis sβ The collection of can be realized through the following implementation methods:

[0103] First, sample the real-time induction motor stator A-phase current i A , Stator B-phase current i B , Stator phase C current i C . Then, use the coordinate transformation of formula (9) to obtain the stator current vector i of the induction motor in the stationary αβ coordinate system s Component i on the α axis sα , the stator current vector i s Component i on the β axis sβ .

[0104]

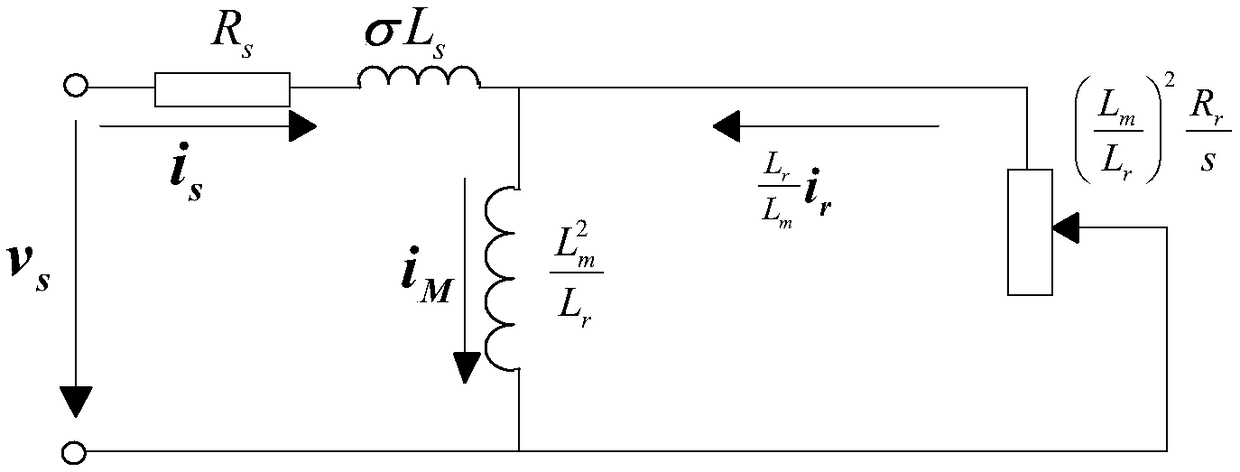

[0105] see figure 1 and image 3 , when step S100 is completed, step S200 can be performed to control the equivalent circuit according to the vector of the induction motor to obtain the excitation current vector i M The expression in the stationary αβ coordinate system:

[0106] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com