Electrothermal film external lead device, and electrothermal film with external lead device

An external lead wire, electric heating film technology, applied in electric heating devices, ohmic resistance heating, ohmic resistance heating parts and other directions, can solve the problems of surface pollution of electric heating film, inconvenient operation, inconsistency in overall appearance, etc., to shorten the production process, The effect of reducing production cost and improving production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

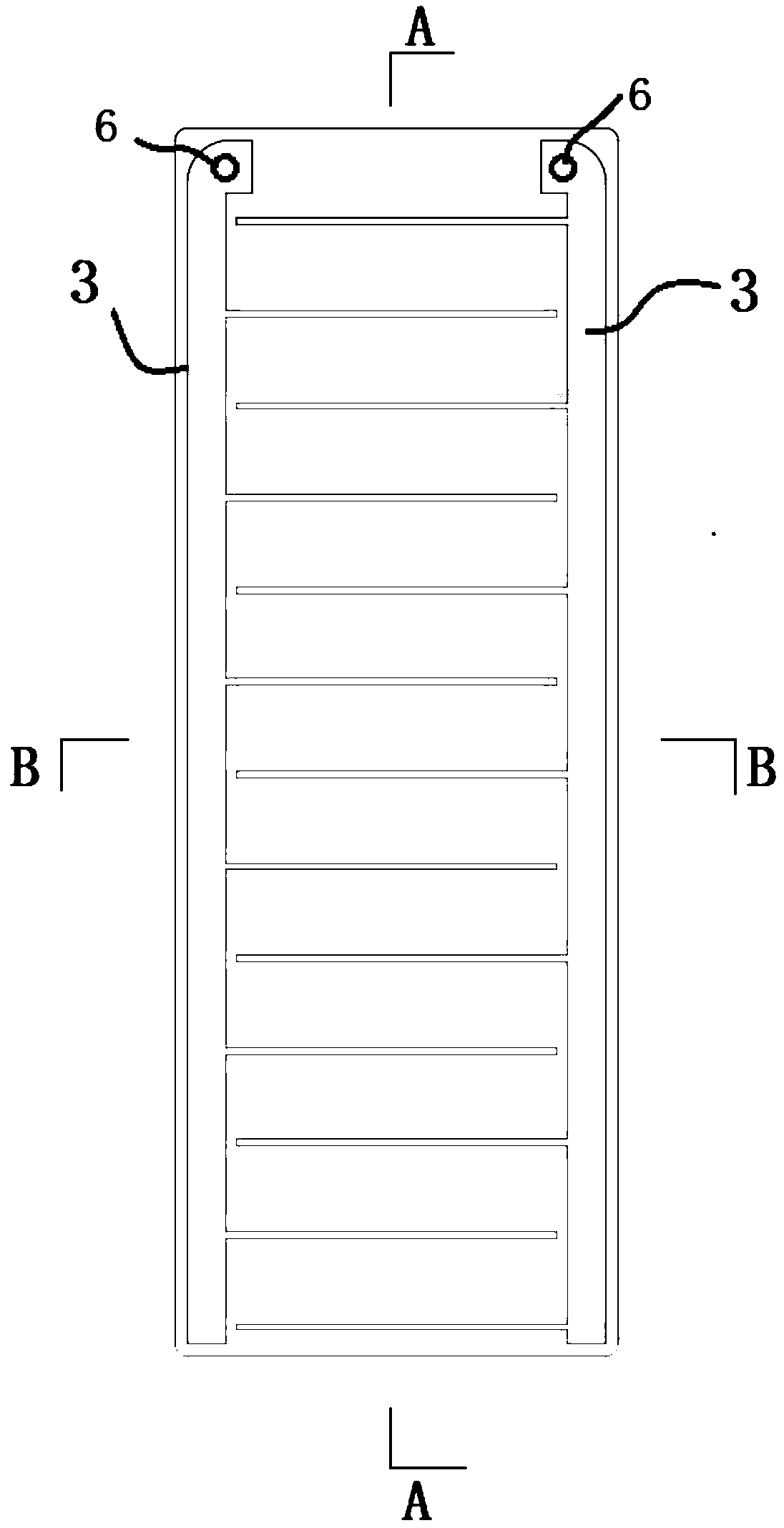

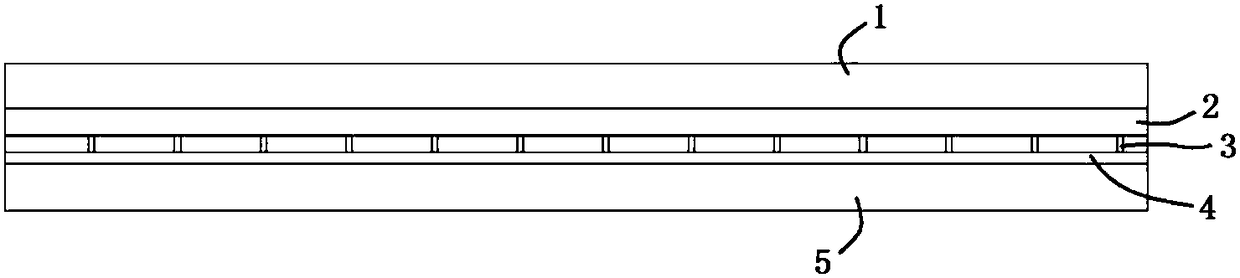

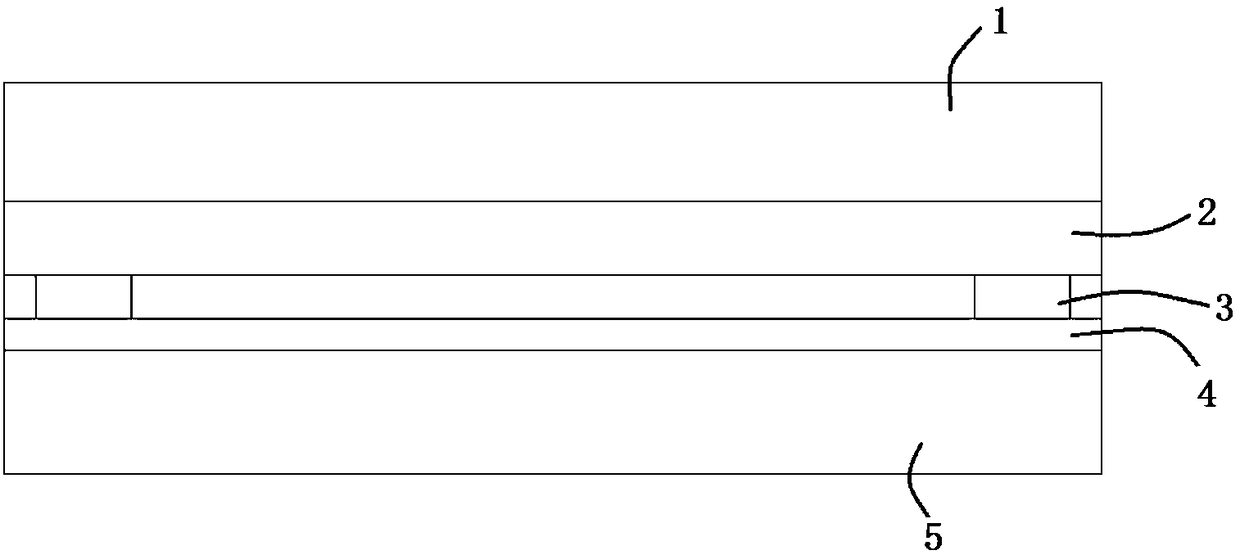

[0072] Such as Figure 6-8 As shown, the first embodiment of the present disclosure provides an electric heating film external lead wire device 100 for connecting the electric heating film to an external power supply or control system.

[0073] Refer below Figure 6-8 The treatment device 100 is described in detail. see Image 6 , combined with Figure 10 , 11 , the external lead device 100 of the present invention includes: a line interface end 101, which is used to couple the electrode 201 of the electrothermal film 200; a line outlet end 102, which is used to connect a power supply; a wire 103, the line interface end 101 and the line outlet end 102 The first insulating layer 104 and the second insulating layer 105 are connected by wires 103 ; the wires 103 are arranged between the first insulating layer 104 and the second insulating layer 105 . Both the first insulating layer 104 and the second insulating layer 105 are made of polyimide or polyester films with a thickn...

Embodiment 2

[0091] The first embodiment of the present disclosure provides an electrothermal film external lead wire device 100, see Figure 9 , 10 , 11, on the basis of the electrothermal film external lead wire device disclosed in embodiment 1, monitoring module interface ports 106, 107 are also provided, and the monitoring module interface ports are exposed conductors for connection with the electrothermal film. Control system connection. For example, the interface port 106 of the monitoring module is used for connecting with the Bluetooth module of the control system, and the interface port 107 of the monitoring module is used for connecting with the thermocouple temperature sensing line of the control system. The exposed conductors of the interface terminals 106 and 107 of the monitoring module are designed according to the interface mode of the control system to be connected to a snap-in structure, a tin welding structure, a through-hole rivet structure or a flexible cable connecto...

Embodiment 3

[0093] Another embodiment of the present disclosure provides an electrothermal film external lead wire device 100, see Figure 12 , the main purpose of the external line leading device provided in this embodiment is to show another line interface terminal 101 . The line outlet end 101 of the external lead wire device 100 provided in Embodiments 1 and 2 uses an obvious metal foil as a bare conductor, which is more suitable for welding and other methods. For the external lead device provided in this embodiment, see Figure 12 As shown, the line outlet port 102 adopts a flexible cable structure. Its connection mode with the electrothermal film is the same as that in Example 1, see for details Figure 13 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com