Laser module

A laser and circuit module technology, applied in the field of electronics, can solve the problems of low circuit efficiency and large size of the laser module, and achieve the effect of satisfying laser noise compliance and avoiding electromagnetic interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

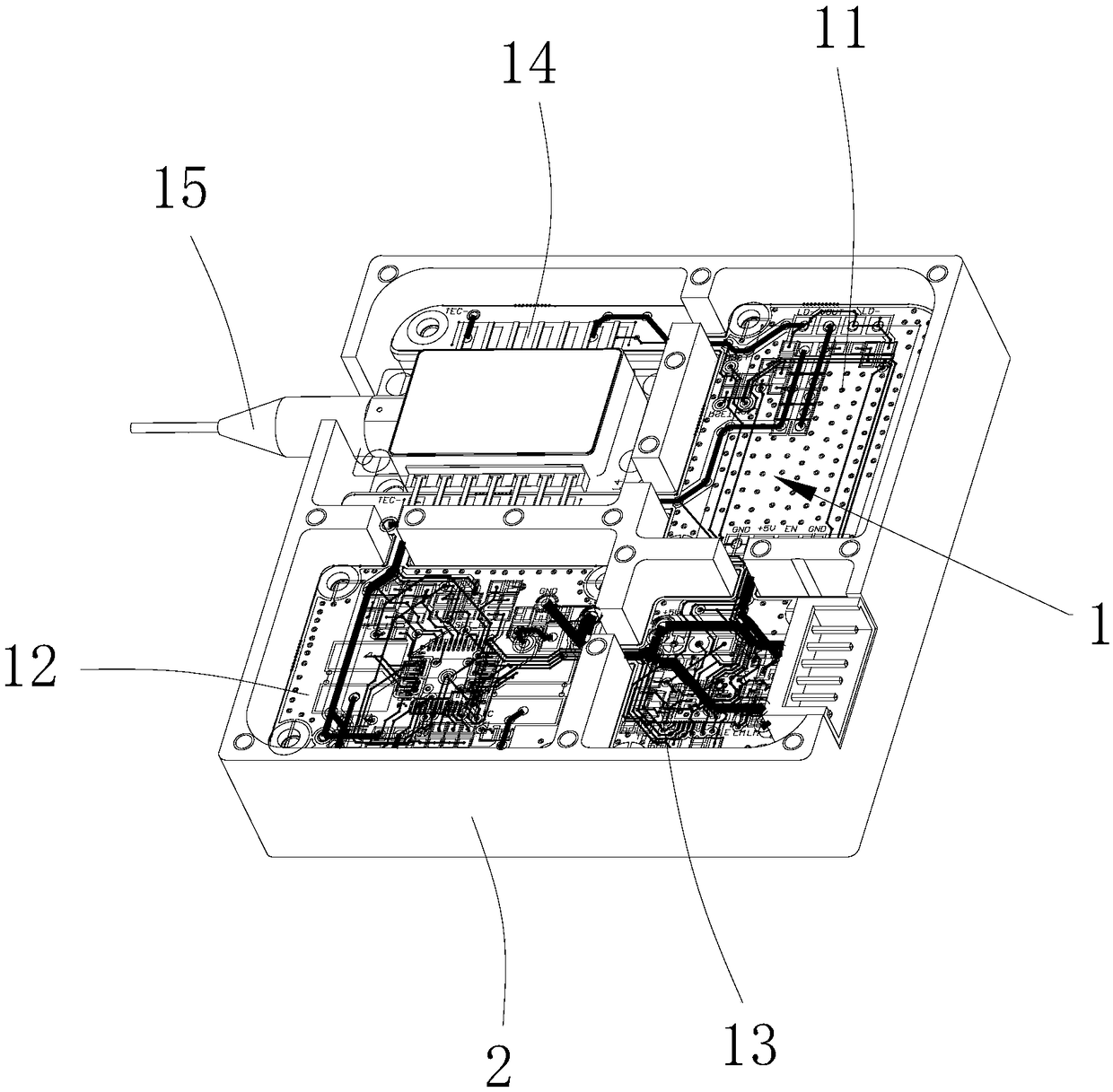

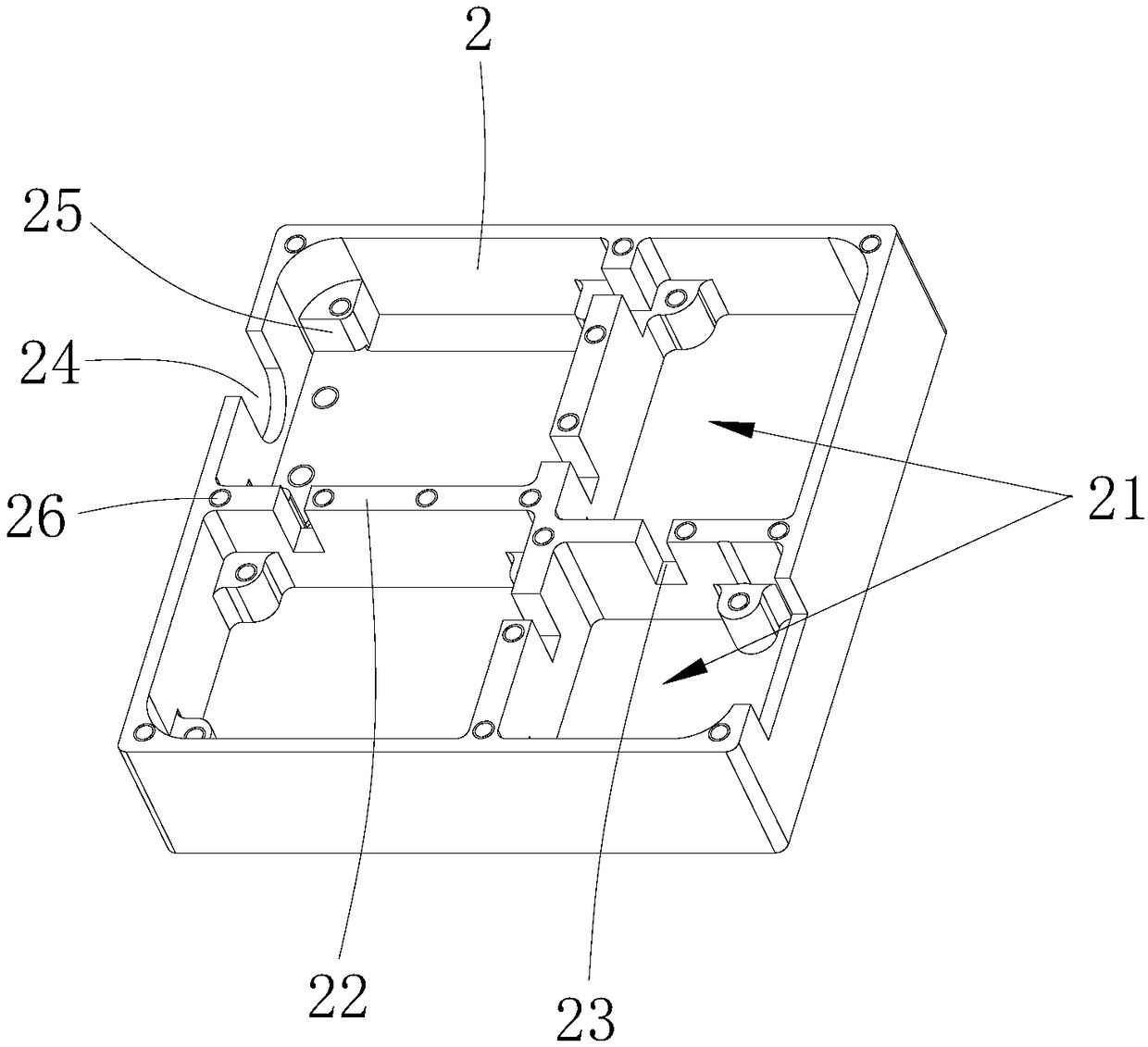

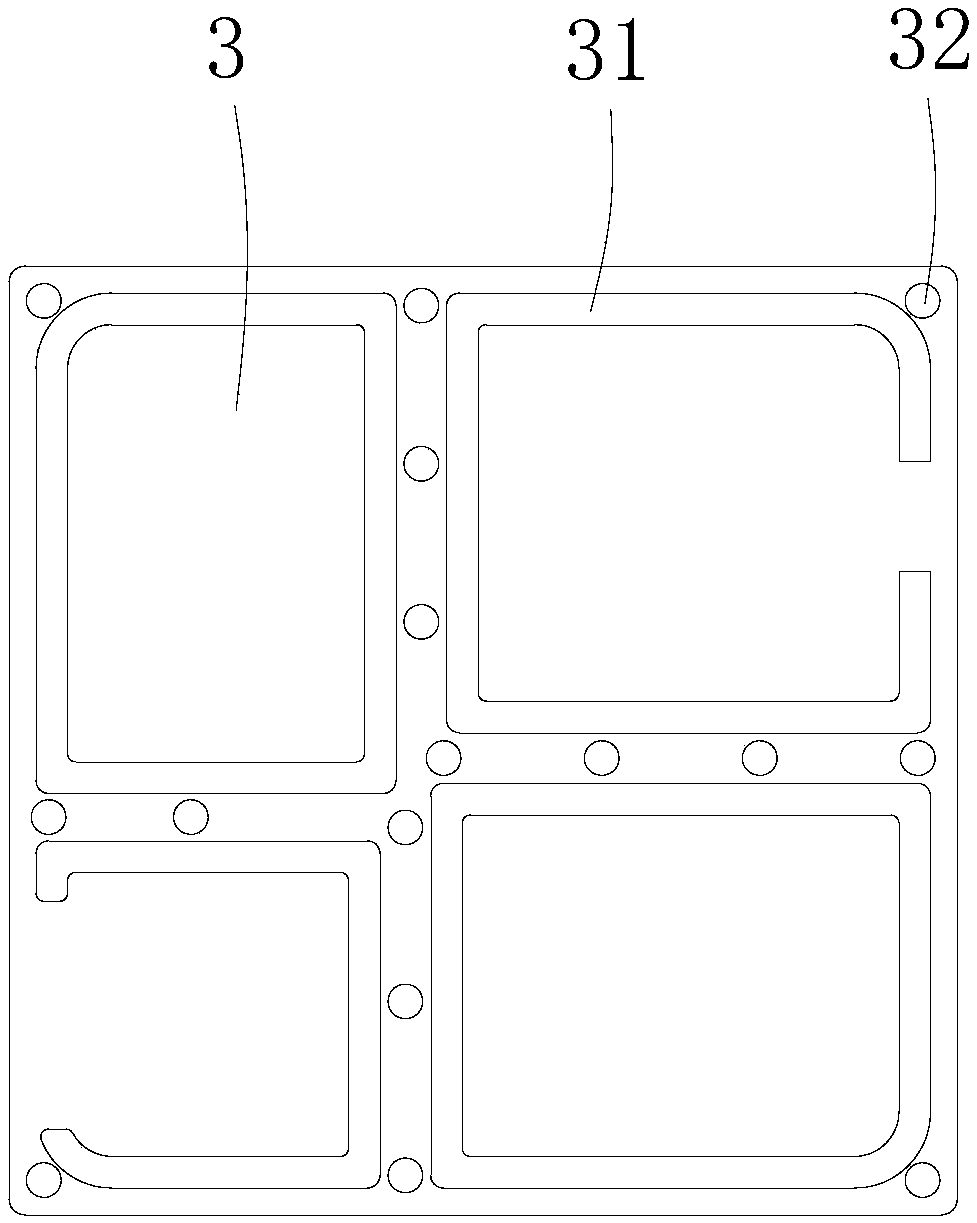

[0026] A laser module, comprising a circuit board 1, a box body 2 for preventing electromagnetic interference and a cover 3 for preventing electromagnetic interference, the cover 3 is set on the box body 2, the circuit board 1 includes a plurality of circuit modules, and the box body 2 is formed with a plurality of installation grooves 21 for placing circuit modules, and each installation groove 21 is set corresponding to each circuit module one by one, and the cover 3 is formed with a protrusion structure 31 for sealing each installation groove 21 .

[0027] In the embodiment of the present invention, each circuit module is enclosed in each installation groove 21 of the box body 2 to avoid electromagnetic interference to other areas, thereby ensuring that the output laser noise of the product meets the standard while meeting the miniaturization requirements of the equipment.

Embodiment 2

[0029] This embodiment is an improvement based on Embodiment 1. The circuit board 1 includes a laser driver module 11, a temperature adjustment module 12, a single-chip microcomputer control module 13 and a laser adapter module 14 that are electrically connected in sequence. There are four mounting slots 21 . The laser driving module 11 mainly completes the current driving function of the laser light-emitting part, which is an ultra-low noise circuit part, and is easily interfered by other parts; the temperature adjustment module 12 mainly completes the temperature adjustment of the laser light-emitting part, so that the light-emitting part emits laser light of a specific wavelength, This part is the larger part of the power, and the power of this part fluctuates greatly under different ambient temperatures, and this part is also the part that produces the larger radiation energy simultaneously; the single-chip microcomputer control module 13 mainly completes the laser module l...

Embodiment 3

[0031] This embodiment is an improvement based on Embodiment 1. Side walls 22 are formed between every two adjacent installation grooves 21, and a notch 23 is formed on each side wall 22, and the notch 23 communicates with each adjacent two installation grooves. Slot 21. The gap 23 is used for the wires between two adjacent circuit modules to pass through.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com