Apparatus for printing on conical objects

A technology for printing devices and articles, which is applied in the directions of printing devices, printing, and electrical recording technology using charge graphics, and can solve the problems of blurred images, shortened service life, and poor printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

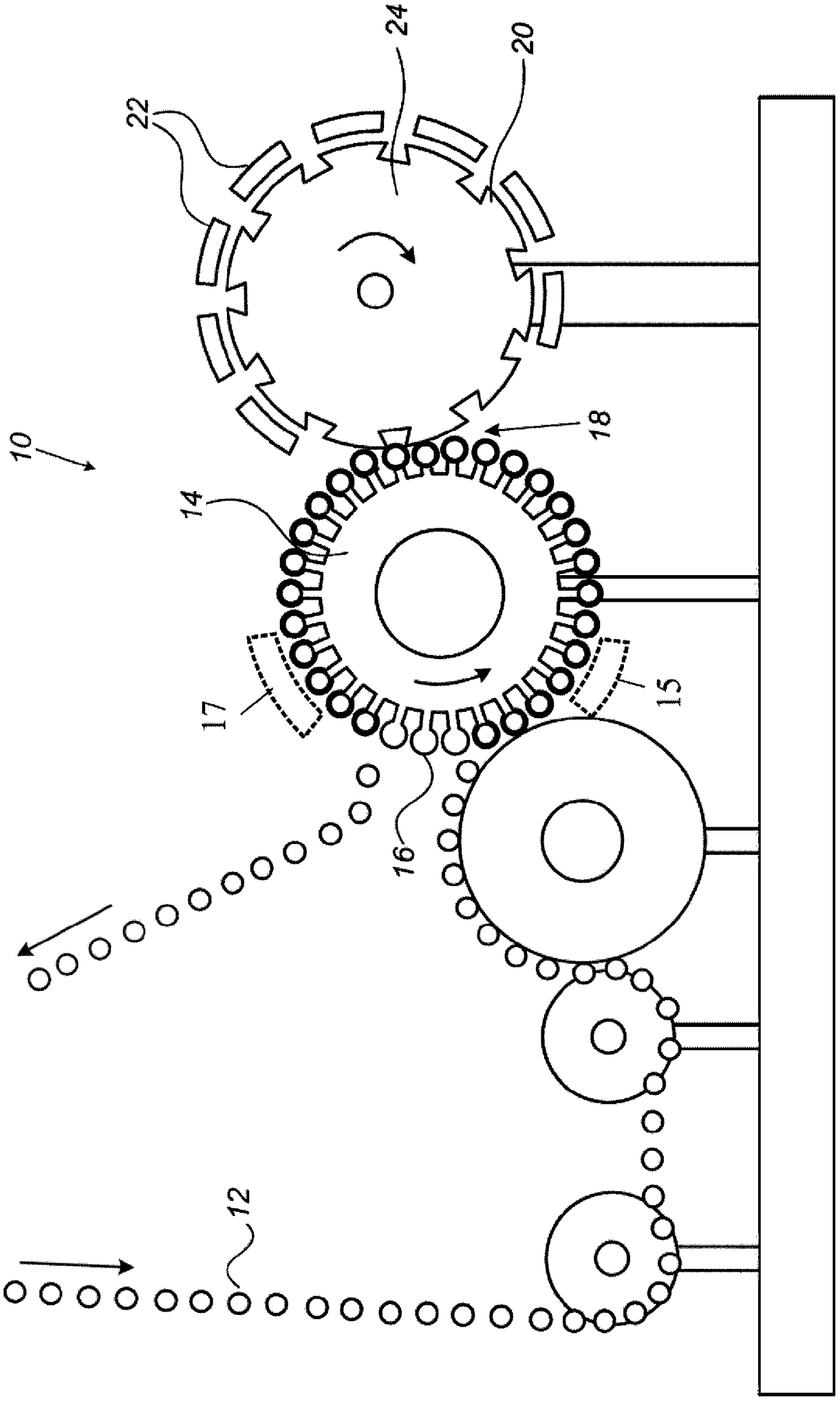

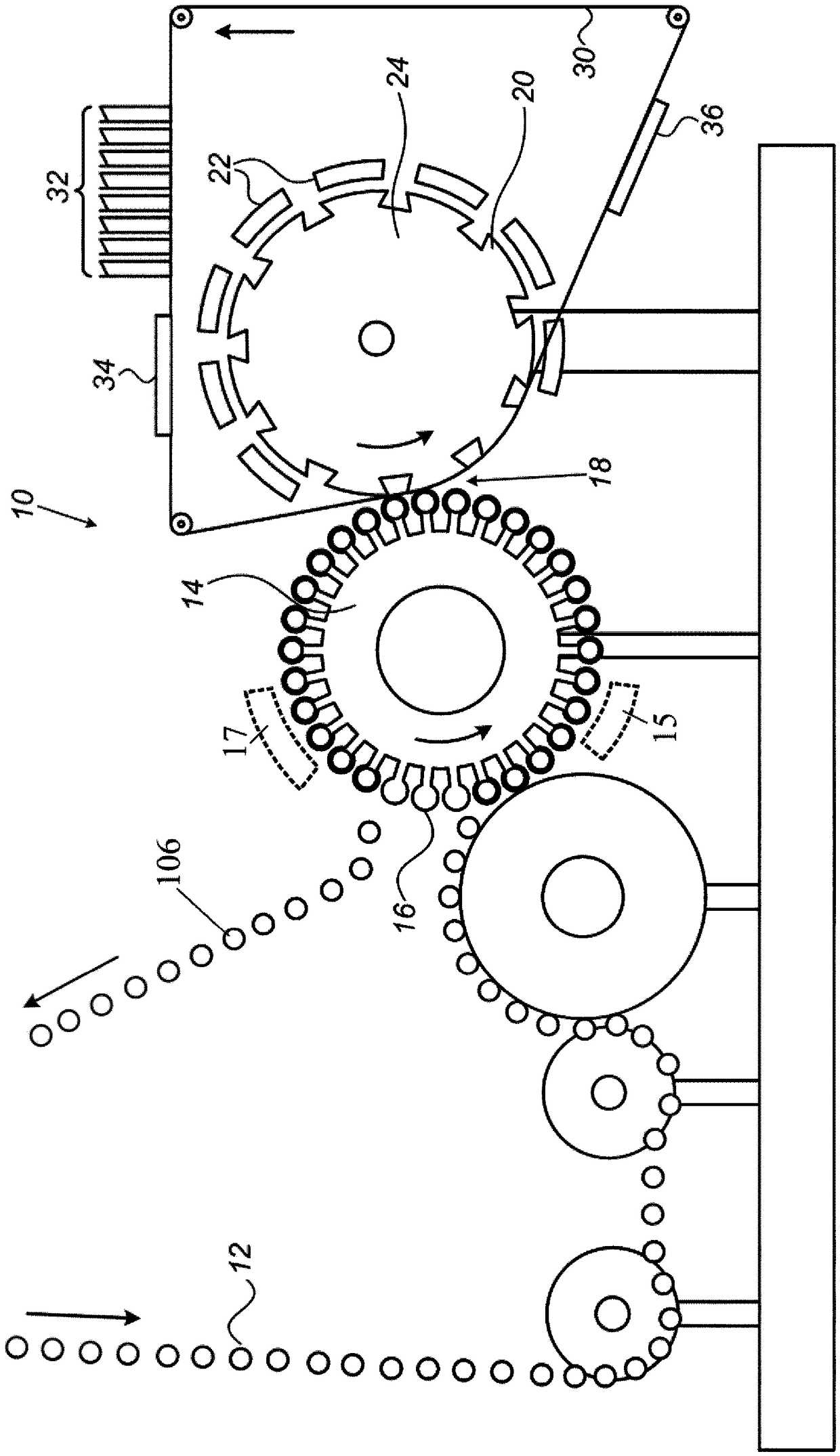

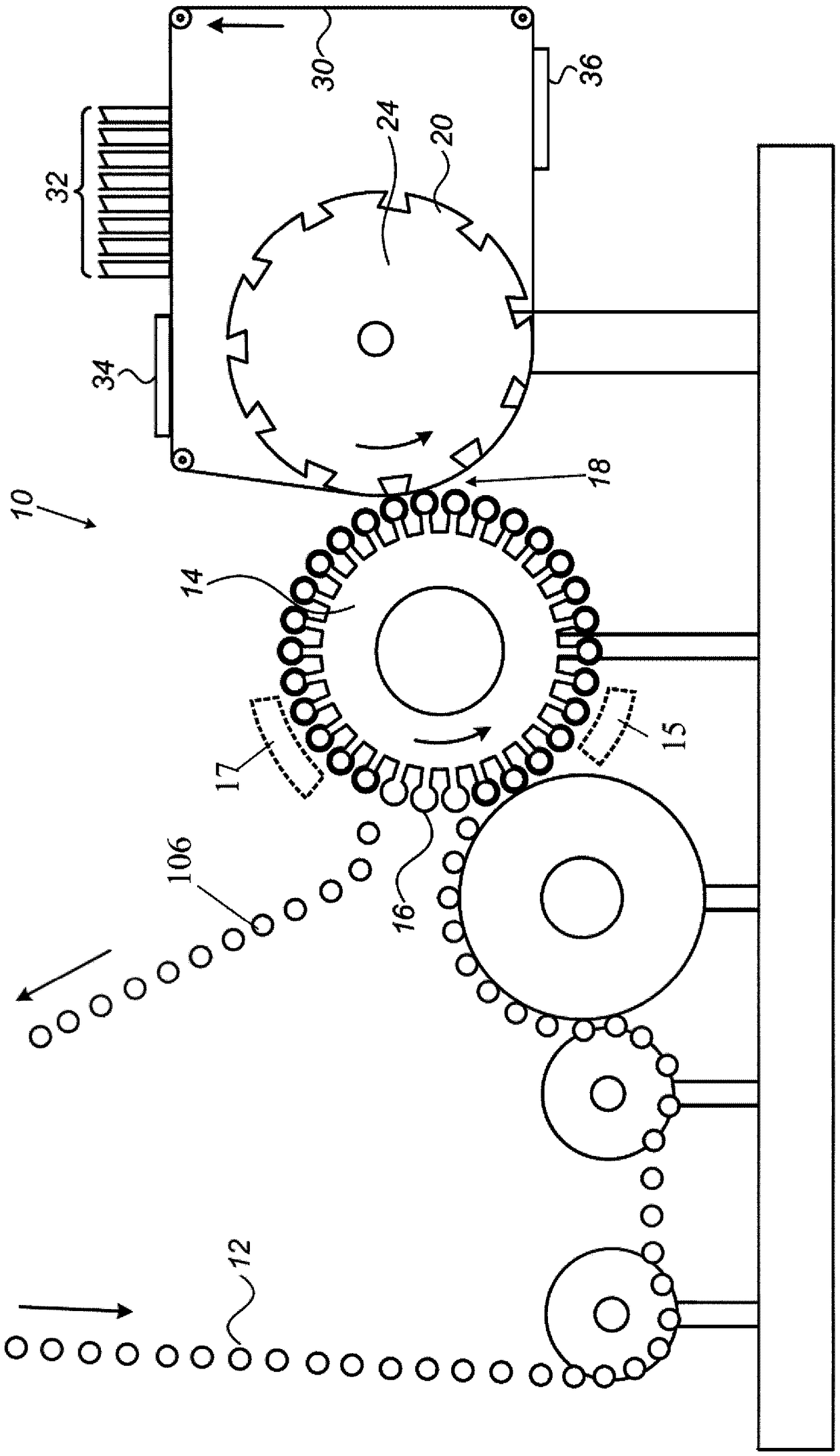

[0058] The ensuing description, together with the accompanying drawings, will clearly enable those skilled in the relevant art to understand how to practice the teachings of the present disclosure by way of non-limiting example. The drawings are for purposes of illustrative discussion and are not intended to show structural details of the embodiments in more detail than is necessary for a fundamental understanding of the present disclosure. For the sake of clarity and simplicity, some objects depicted in the drawings have not been drawn to scale. Although the present invention and the appended claims relate only to systems for printing on conical items, the following disclosure describes both systems for printing on cylindrical and The embossing station of the printing system was modified to enable it to print on conical items. This can be achieved by modifying the path of the ITM so that one of its sides is stretched more than the other during passage through the embossing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com