A simple and efficient preparation method of zinc sulfide semiconductor thin film

A technology of zinc sulfide and semiconductor, which is applied in the direction of zinc sulfide, liquid-coating devices on the surface, coatings, etc., can solve the problems of strict experimental conditions, expensive, long reaction time, etc., and achieve high crystal quality, low cost, and high composition easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The aqueous solution of sodium xanthate and zinc nitrate is reacted in a single step to generate zinc xanthate precipitate, and then filtered, washed, and dried to obtain zinc xanthate precursor powder. Weigh 0.019 g of zinc ethyl xanthate powder, dissolve and disperse in 2 ml of pyridine to form a uniform transparent solution, drop the transparent solution onto a glass slide, anneal for 120 minutes at a temperature of 110°C in an air atmosphere, and cool Take out the glass sheet at room temperature, and you can find that a uniform film is formed on the glass sheet.

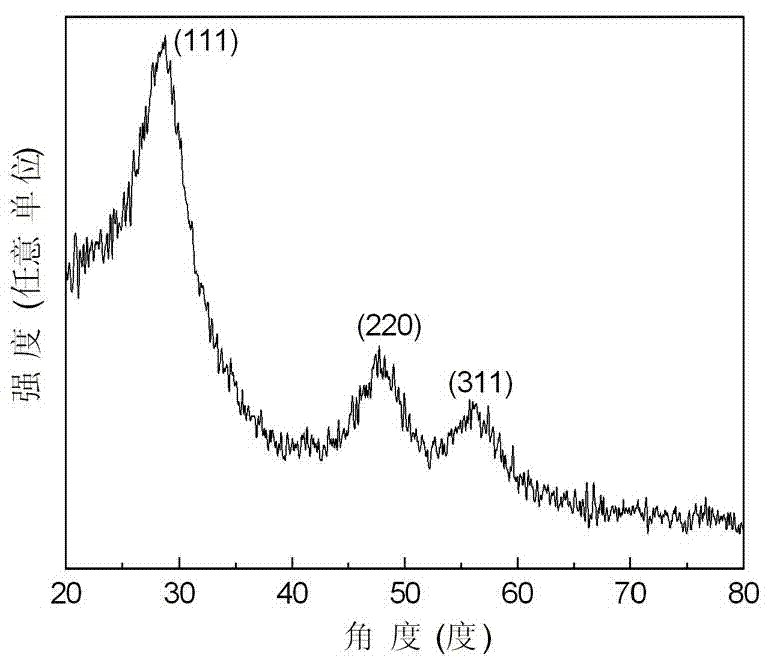

[0025] attached figure 1 It is the X-ray diffraction spectrum of the zinc sulfide thin film that embodiment 1 prepares, can confirm that this is the zinc sulfide of cubic structure by figure.

Embodiment 2

[0027] Take 10 mL of ethanol and 0.40 g of sodium hydroxide, mix and stir until the sodium hydroxide is completely dissolved, add 1.4 mL of carbon disulfide and stir for 2 hours. Then 0.136 g of zinc chloride was dissolved in 50 mL of acetone, added to the above solution and stirred for 2 hours, and the filtrate was filtered and volatilized naturally at room temperature to obtain the precursor powder of zinc ethyl xanthate, a coordination polymer. Weigh 0.28g of zinc ethyl xanthate powder, dissolve and disperse in 2ml of 2-picoline to form a uniform and transparent solution, and spin-coat the transparent solution onto a silicon wafer at a temperature of 350°C under a nitrogen atmosphere Anneal for 5 minutes, cool to room temperature and take out the silicon wafer. It can be found that a uniform film is formed on the silicon wafer.

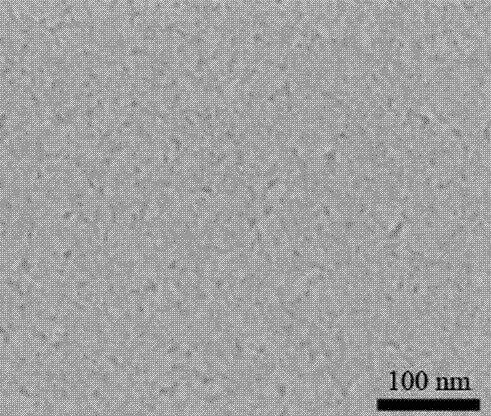

[0028] attached figure 2 The scanning electron micrograph of the zinc sulfide film prepared in Example 2 shows that the zinc sulfide film is eve...

Embodiment 3

[0030] The aqueous solution of potassium xanthate and zinc chloride is reacted in a single step to form a zinc xanthate precipitate, and then filtered, washed, and dried to obtain a zinc xanthate precursor powder. Weigh 0.45g of zinc ethyl xanthate powder, dissolve and disperse in 1 ml of pyridine to form a uniform transparent solution, drop the transparent solution onto a plastic sheet, anneal at 160°C for 25 minutes under vacuum, and cool to Take out the plastic sheet at room temperature, and you can find that a uniform film is formed on the plastic sheet.

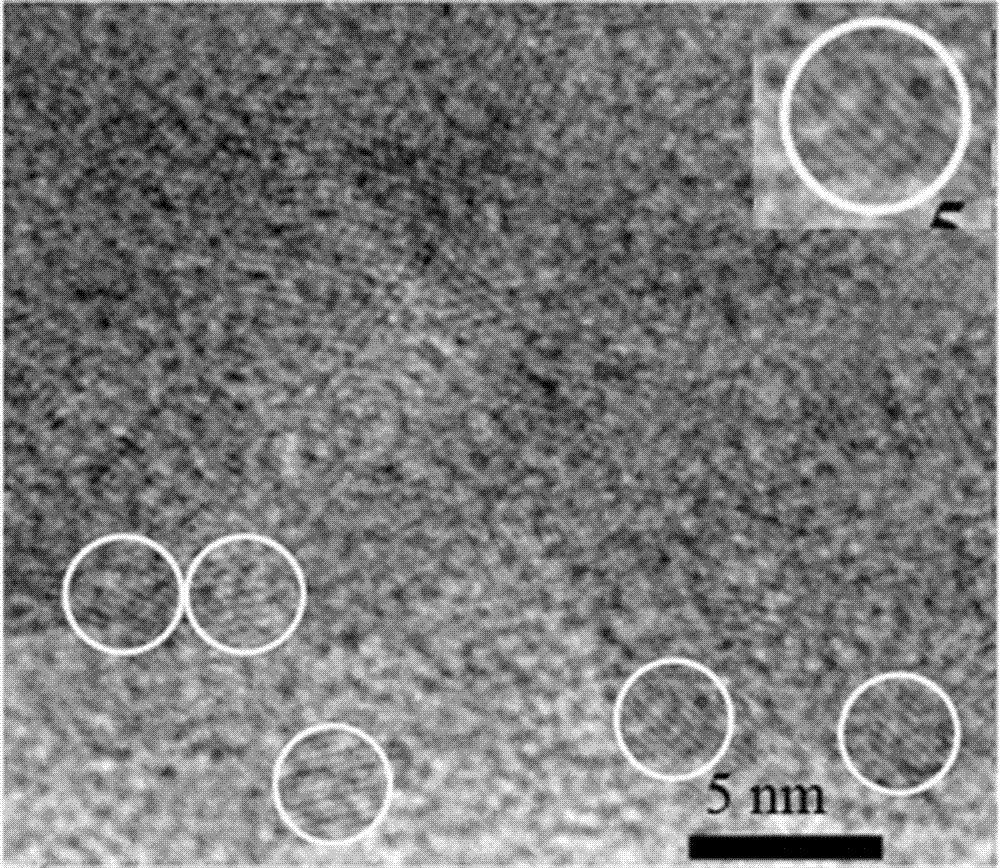

[0031] attached image 3 The transmission electron micrograph of the zinc sulfide thin film prepared for Example 3 shows that the zinc sulfide nanoparticles are mostly spherical, and the diameter of the zinc sulfide nanoparticles is about 2-3 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com