Optical member and liquid crystal display device

A technology of optical components and protective covers, applied in optical elements, optics, nonlinear optics, etc., can solve problems such as uneven rainbow and reduced brightness, and achieve low cost and suppress the reduction of visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] 1. Fabrication of polarizers

[0060] A polyvinyl alcohol film with a thickness of 80 μm was stretched 3 times while being dyed in a 0.3% iodine solution at 30° C. for 1 minute between rolls having different speed ratios. Thereafter, it was stretched to a total draw ratio of 6 times while being immersed in an aqueous solution containing 4% boric acid and 10% potassium iodide at 60° C. for 0.5 minutes. Next, after washing|cleaning by immersing in the aqueous solution containing the potassium iodide of 1.5% density|concentration at 30 degreeC for 10 second, it dried at 50 degreeC for 4 minutes, and obtained the polarizer. A saponified triacetyl cellulose film having a thickness of 80 μm was bonded to both surfaces of the polarizer with a polyvinyl alcohol-based adhesive to prepare a polarizing plate (polarizing film).

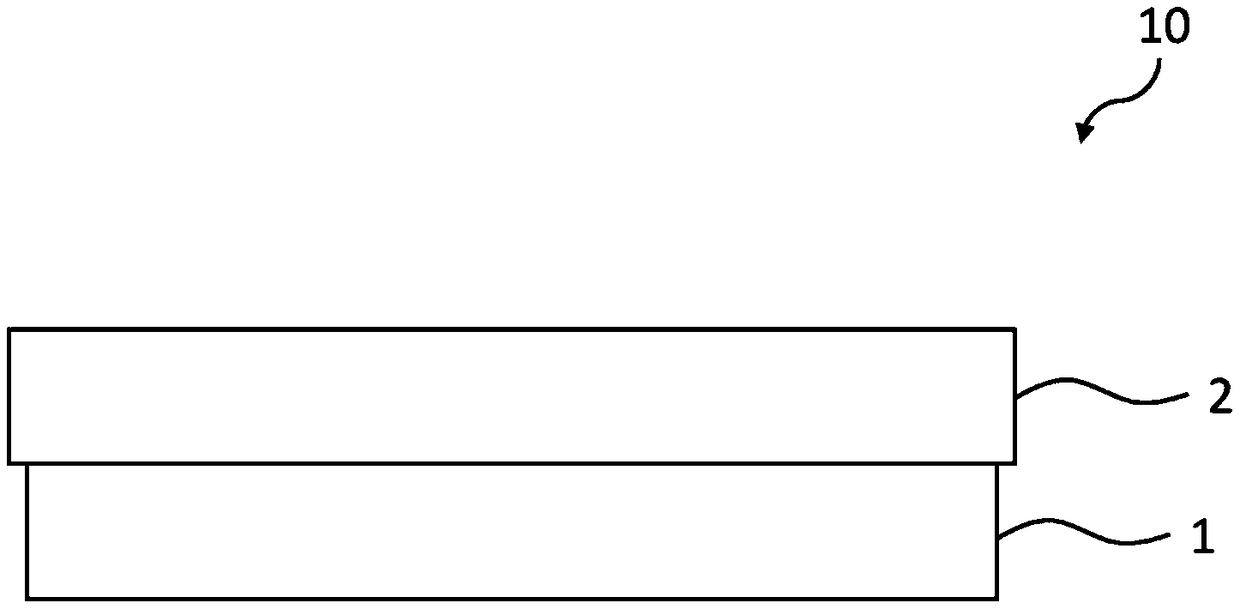

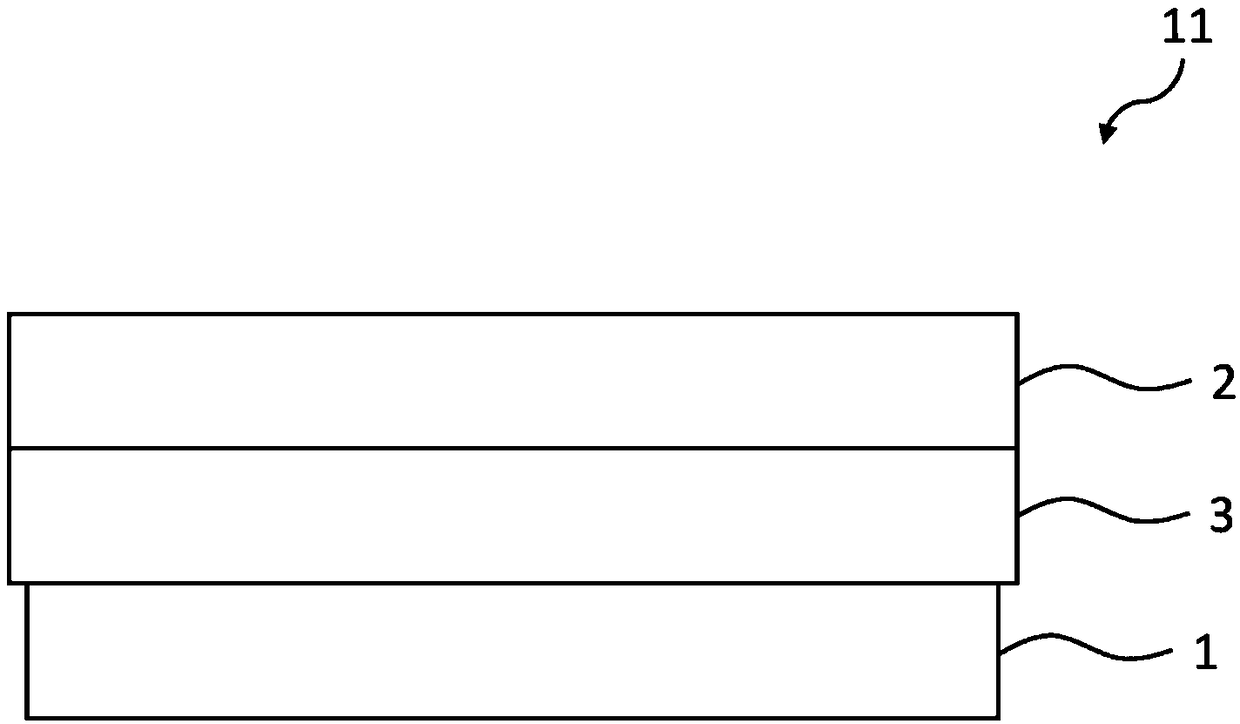

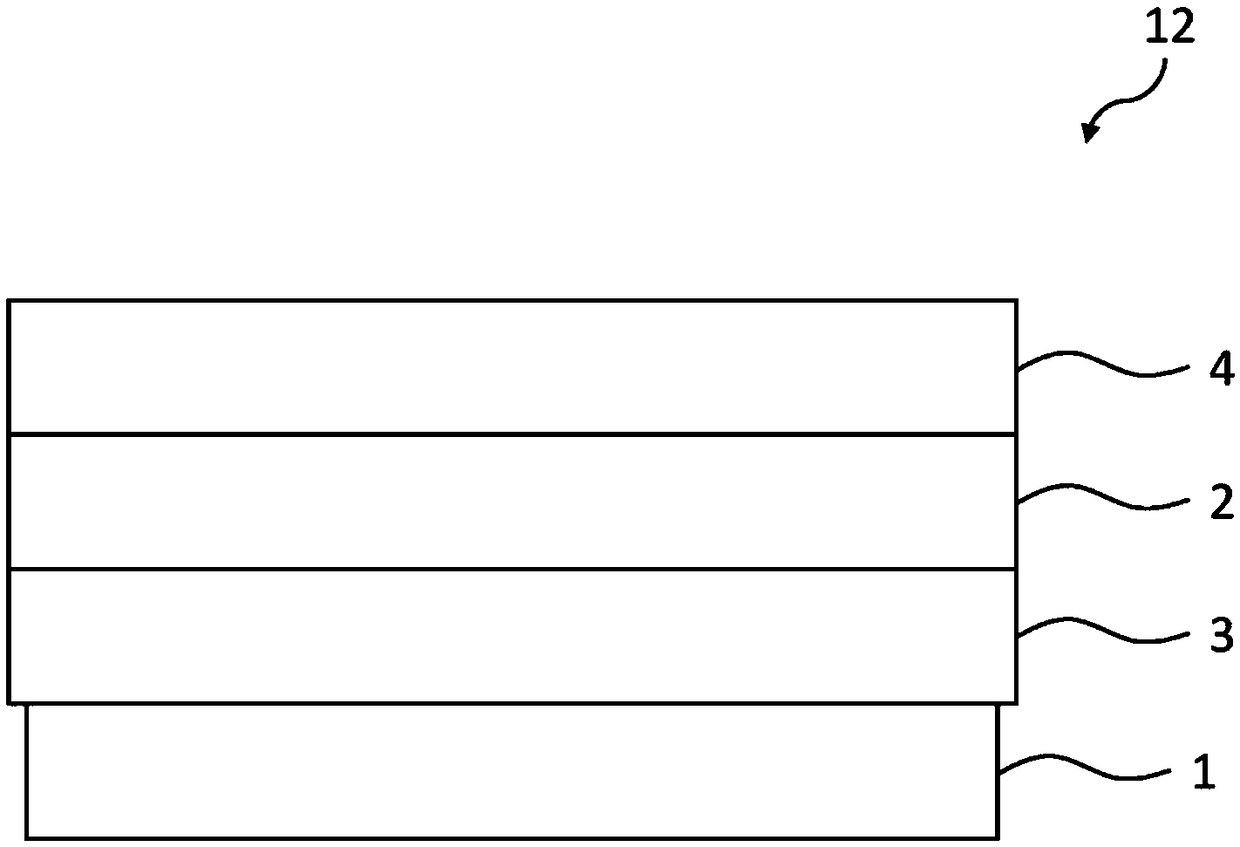

[0061] 2. Fabrication of optical components

[0062] As the protective cover, a plastic cover (manufactured by Mitsubishi Gas Chemical Co., Ltd., produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com