Method for preparing circularly-polarized luminescent material with high luminescence dissymmetry factor

An asymmetric and circularly polarized technology, which is applied in the field of preparing circularly polarized luminescent materials with a high luminous asymmetry factor, can solve the problems of lengthy and complicated preparation process and low yield, and achieve simple method, low environmental dependence and high application promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] In the present embodiment, the structural formula of formula a is as shown in the figure below:

[0065]

[0066] The specific steps are:

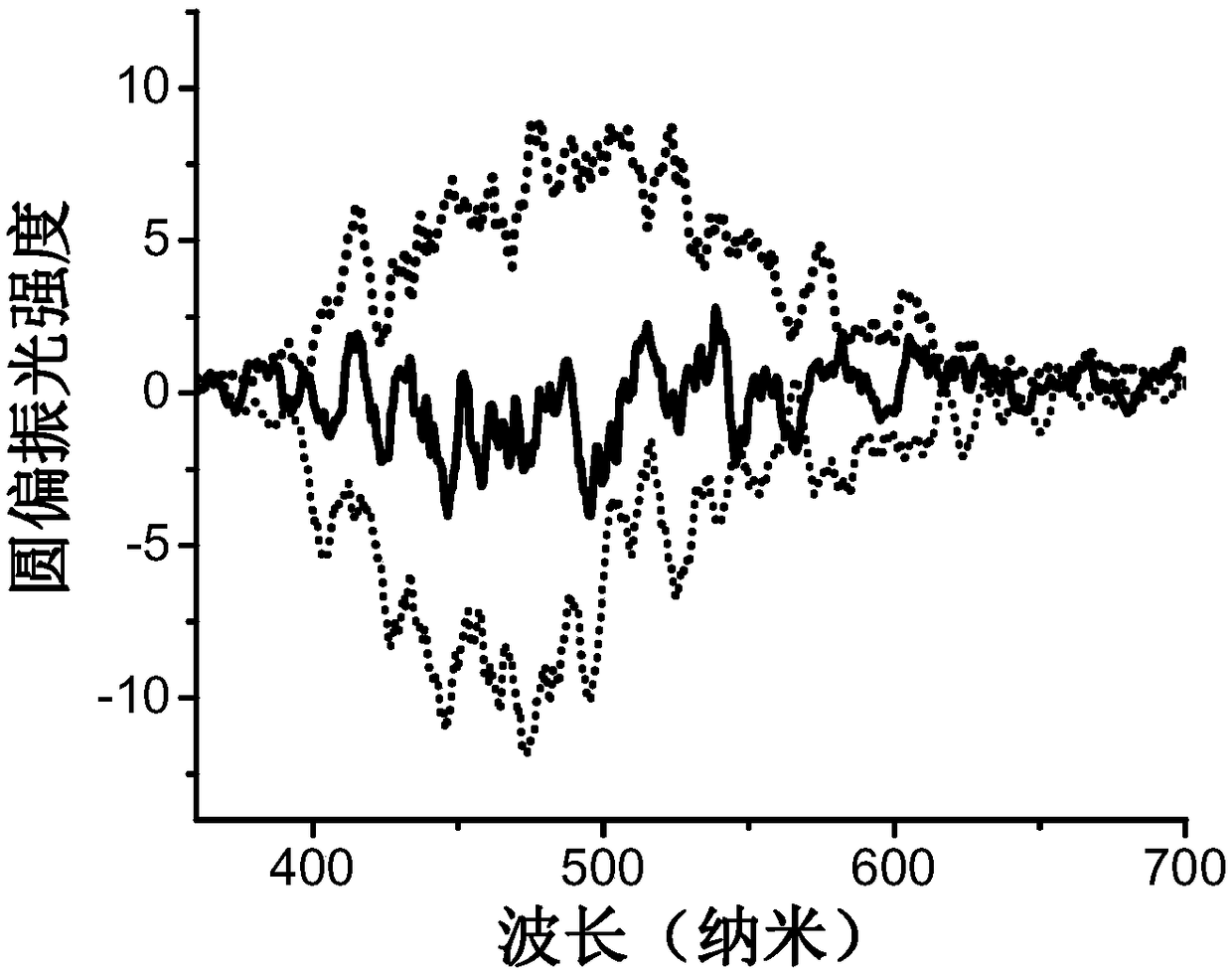

[0067] 1) Take a clean sample bottle, weigh 3 mg of the small organic molecule shown in formula a, pipette 700 μL of good solvent (DMF) to dissolve it completely, add 300 μL of poor solvent ultrapure water to obtain a white gel. Measure its CPL spectrum. CPL spectrum see attached figure 1 . After calculation, its g lum 5.81×10 -4 . It can be seen that the circularly polarized luminescence performance of the organic small molecule represented by formula a is low, and the circularly polarized luminescence is often not detected.

[0068] 2) Heat the sample bottle until the white gel is completely dissolved and becomes a transparent solution.

[0069] 3) Apply vortex mixing (intensity of 2500rpm), while controlling the system temperature, programmatically cool down to room temperature (about 25°C) at a rate of 10°C / min to obta...

Embodiment 2

[0071]

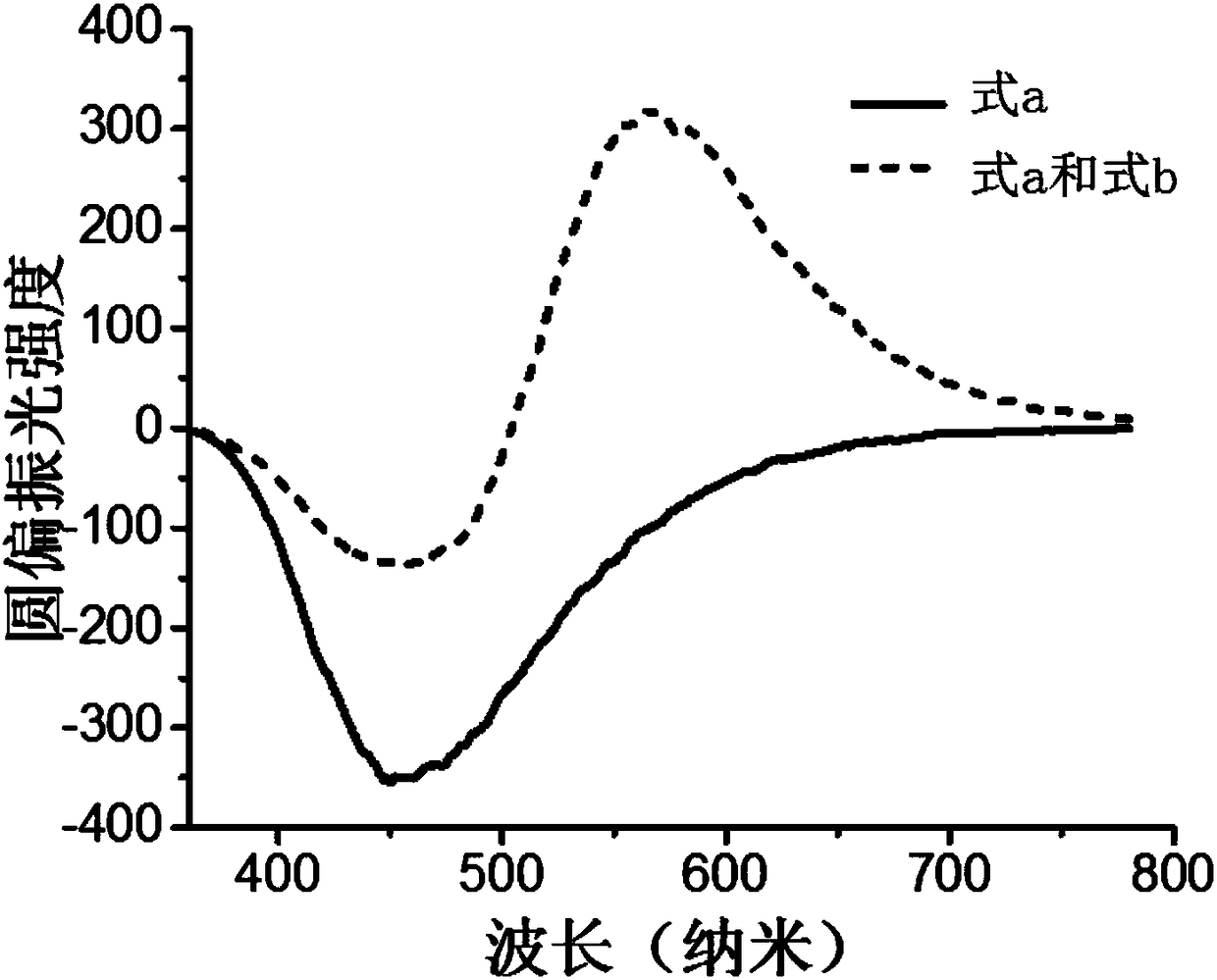

[0072] Take 0.12 mg of the dye molecule compound shown in formula b (the molar ratio of formula b to formula a is 0.05:1) and add it into the white suspension obtained in step 3) of Example 1 during the process of vortex mixing until formula a and Formula b can be mixed evenly. Measure its CPL spectrum. CPL spectrum see figure 2 . After calculation, the g of the composite system of formula a and formula b lum 4.67 x 10 -2 .

Embodiment 3

[0074] According to the steps of Example 2, only the dye molecule compound shown in formula b is replaced with the dye molecule compound shown in formula c below:

[0075]

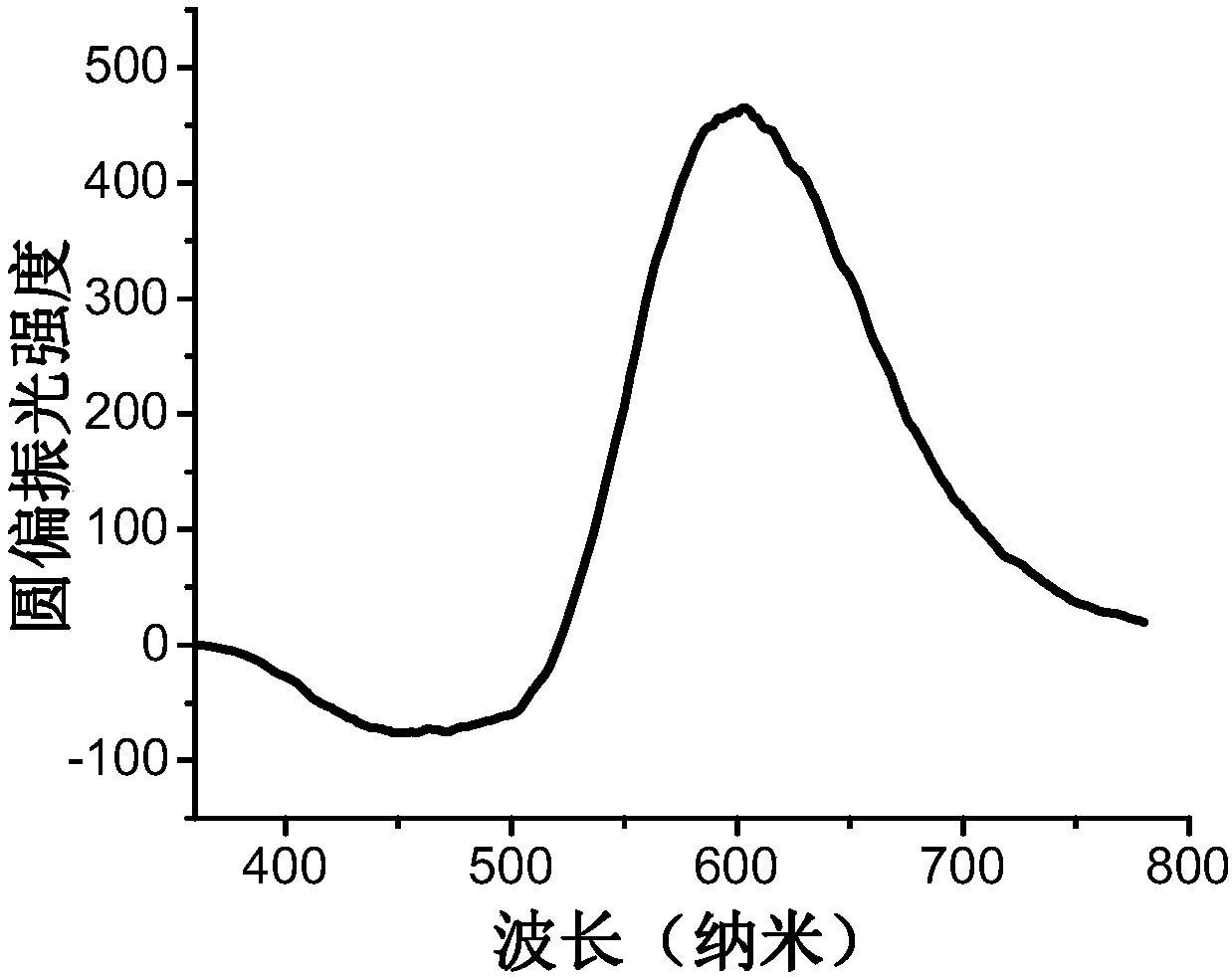

[0076] image 3 is the CPL spectrum of the composite system of formula a and formula c. After calculation, its g lum is 6.47×10 -2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com