Self-balancing forward and backward continuous cycle operation device

A circulating operation and self-balancing technology, which is applied to wellbore/well valve devices, wellbore/well parts, earthwork drilling and production, etc., can solve problems such as increasing the risk of pipe sticking, reducing construction efficiency, and poor circulation channels , to achieve the effect of improving site applicability and flexibility, improving construction reliability and ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings:

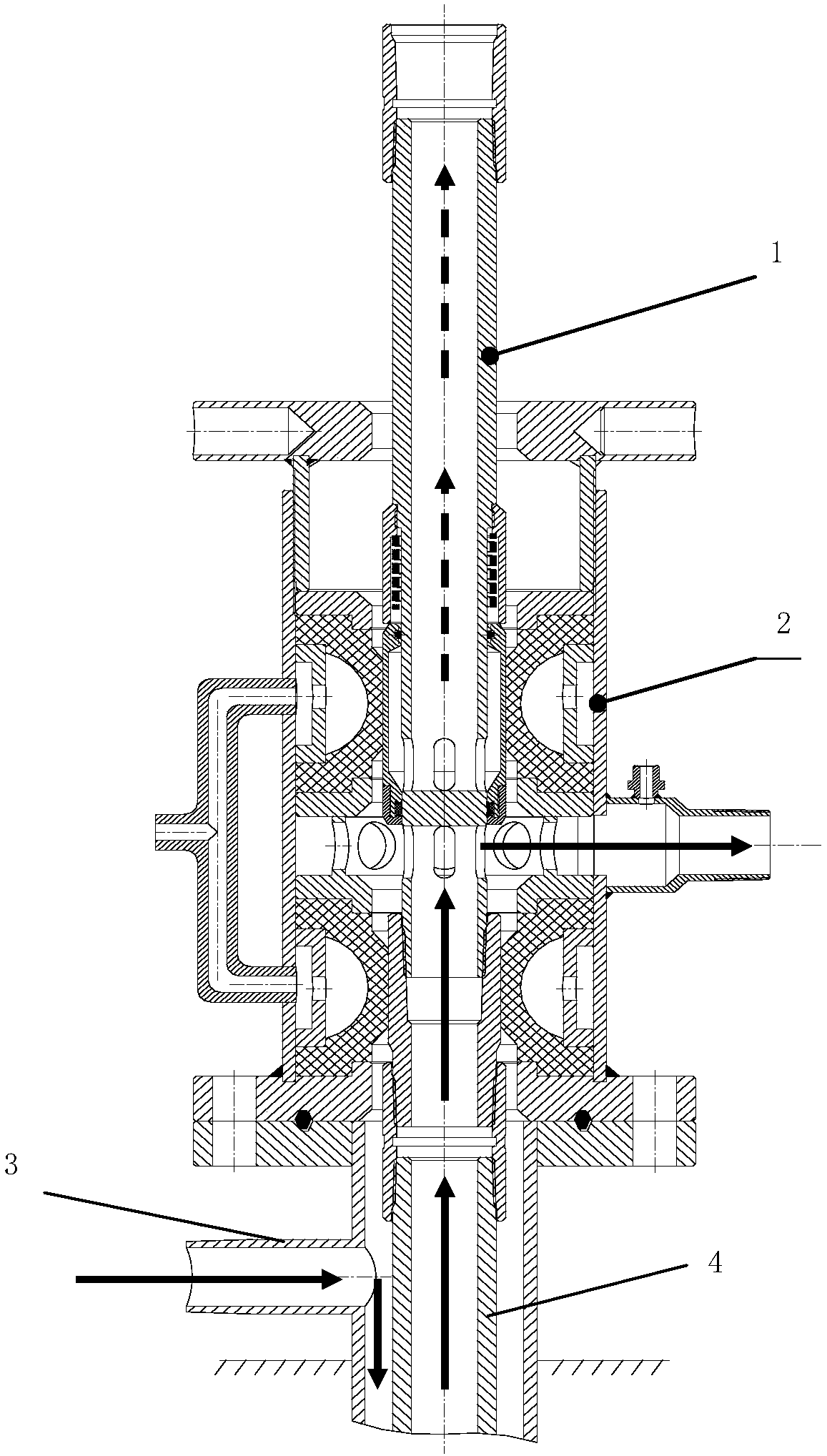

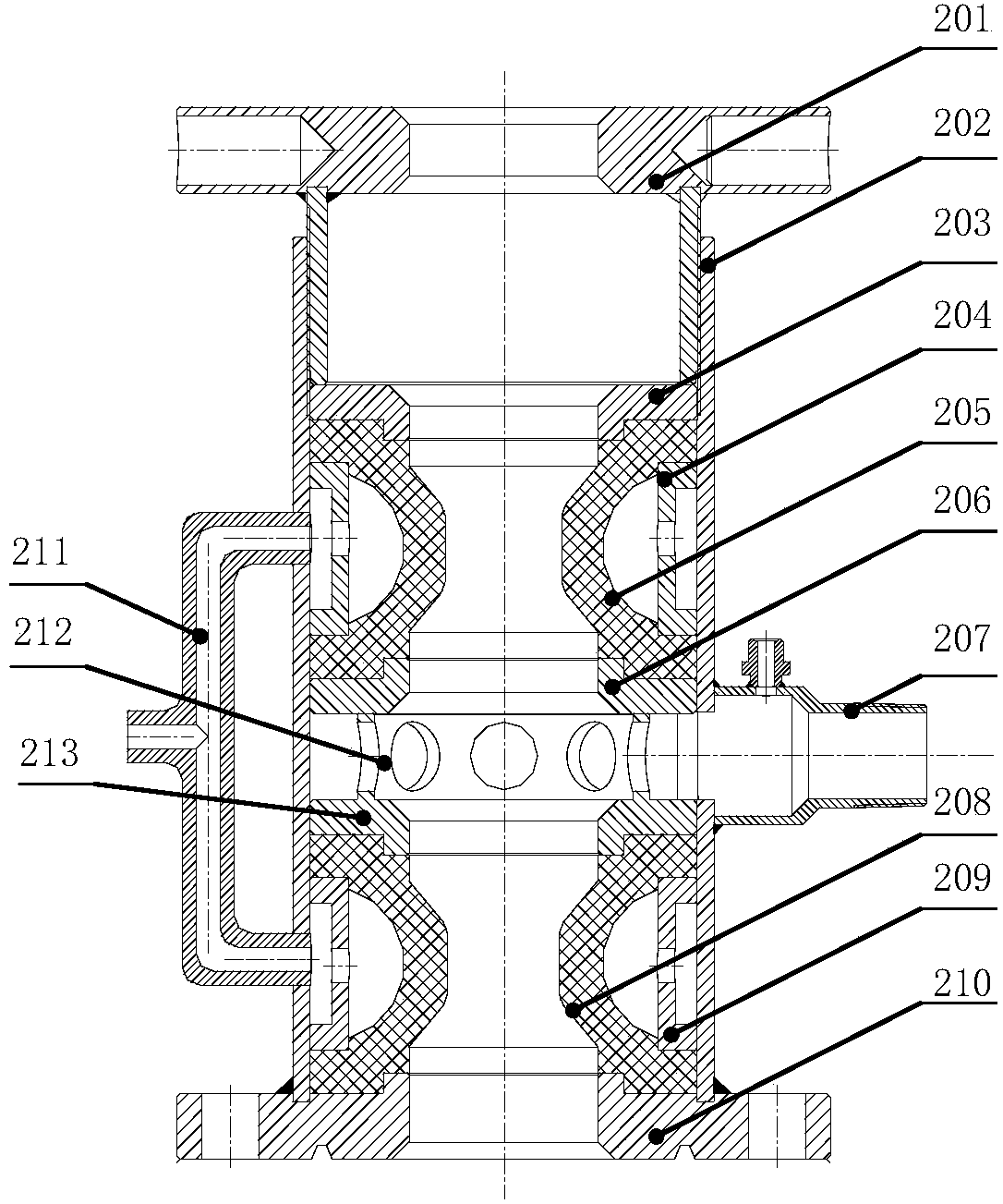

[0028] See Figure 1 to Figure 3 , A self-balancing positive and negative bidirectional continuous cycle operation device, which mainly includes two parts: reversing sub 1 and reversing wellhead 2:

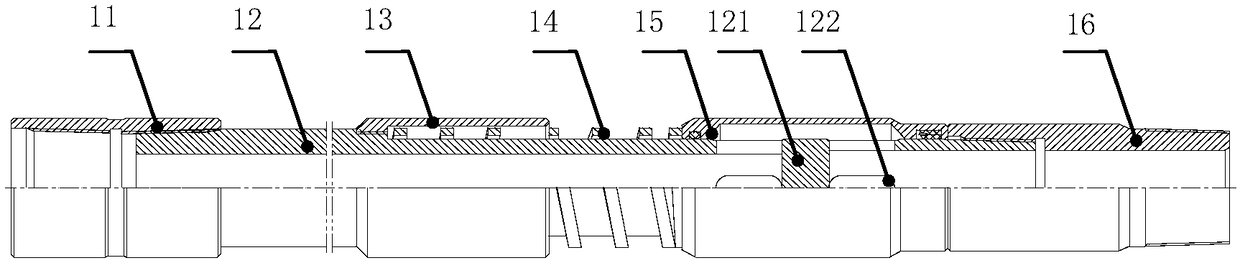

[0029] A. The reversing sub 1 is composed of an upper joint 11, a central tube 12, a spring seat 13, a return spring 14, a sliding sleeve 15, and a lower joint 16. Both ends of the upper joint 11 are processed with taper pipe internal threads (tubing female buckle), one end of which is connected with the taper pipe outer thread (tubing male buckle) of the upper end of the central pipe 12, and the spring seat 13 is sleeved into the central pipe 12 along the axis and fixed by threaded connection. The return spring 14 and the sliding sleeve 15 are similarly sleeved into the central tube 12 along the axis. One end of the return spring 14 is sleeved in the annular space b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com