Portable cutting machine

A cutting machine, portable technology, applied in the direction of welding/cutting auxiliary equipment, metal processing machinery parts, large fixed members, etc., can solve the problems of loss, complex structure, personal hazards, etc., and achieve light weight, small size, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

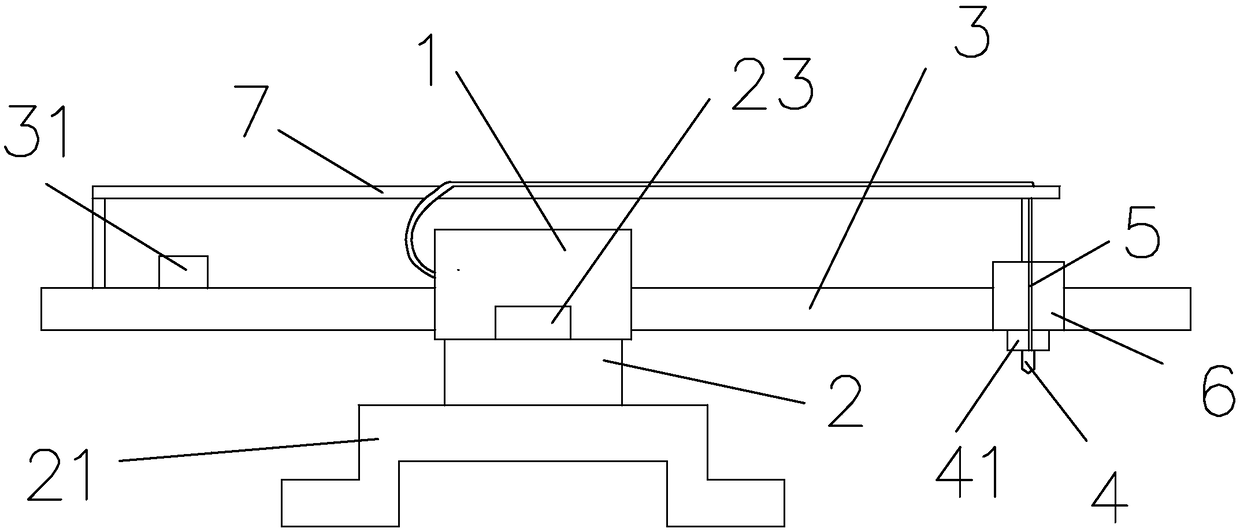

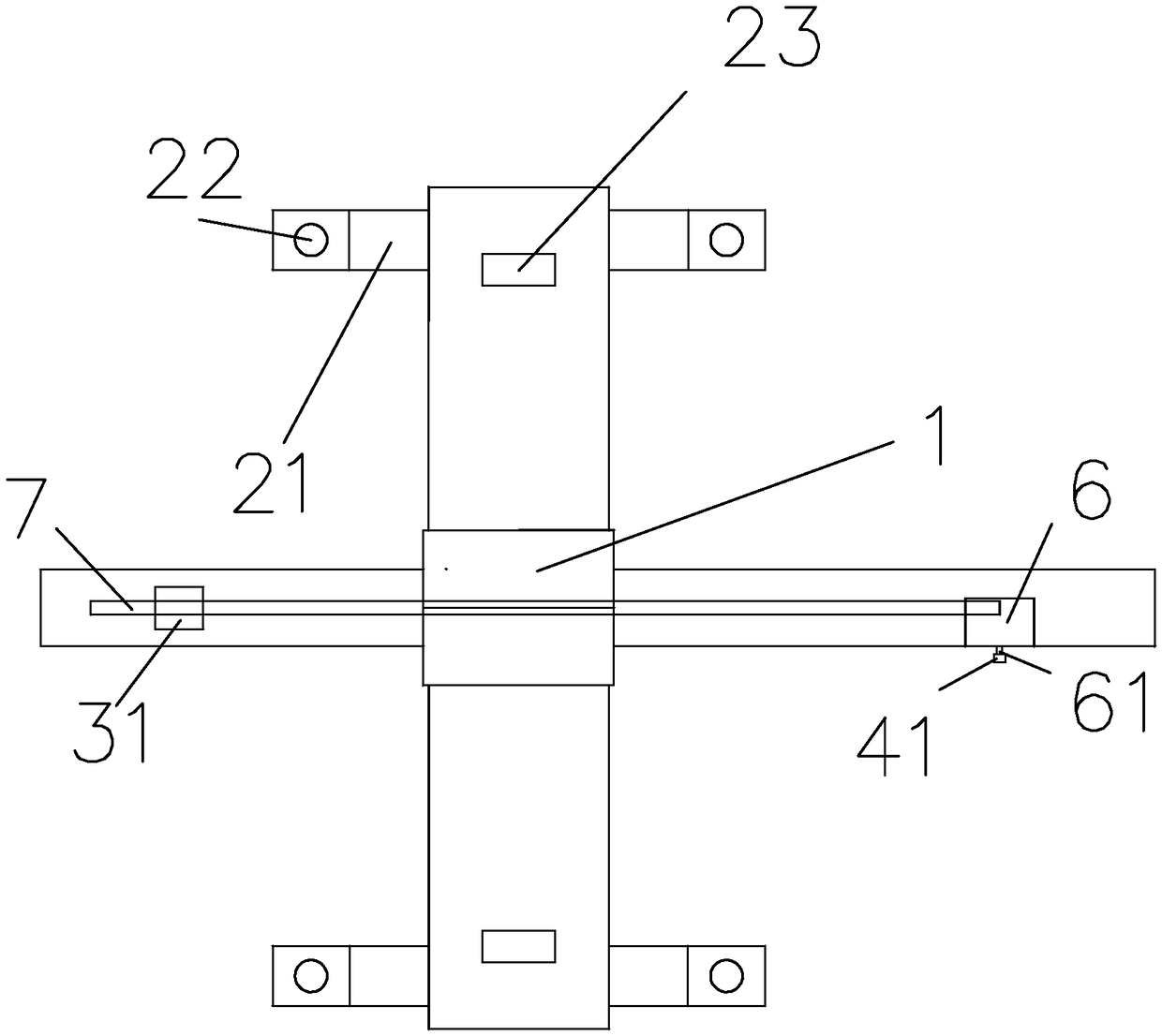

[0017] refer to Figure 1 to Figure 2 Shown, a kind of portable cutting machine in the present embodiment comprises main engine, and main engine comprises electric control system 1, longitudinal track 2, transverse track 3, cutting nozzle 4, gas wire 5, elevating mechanism 6 and beam 7, and transverse track 3 from The electric control system 1 passes through the interior, the longitudinal rail 2 is set under the electric control system 1, the horizontal rail 3 and the longitudinal rail 2 are perpendicular to each other, and a lifting mechanism 6 is arranged on one side of the horizontal rail 3, and the extending end of the lifting mechanism 6 passes through the connecting piece 61 is connected with the cutting nozzle 4, the gas wire 5 is connected to the cutting nozzle 4, the beam 7 is arranged above the transverse rail 3, the gas wire 5 protrudes from the electric control system 1 and is fixed on the beam 7, and the transverse rail 3 is connected to the electric control system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com