Rotation disc device of derusting machine

A rust removal machine and turntable technology, which is applied to the parts of grinding machine tools, grinders, metal processing equipment, etc. processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

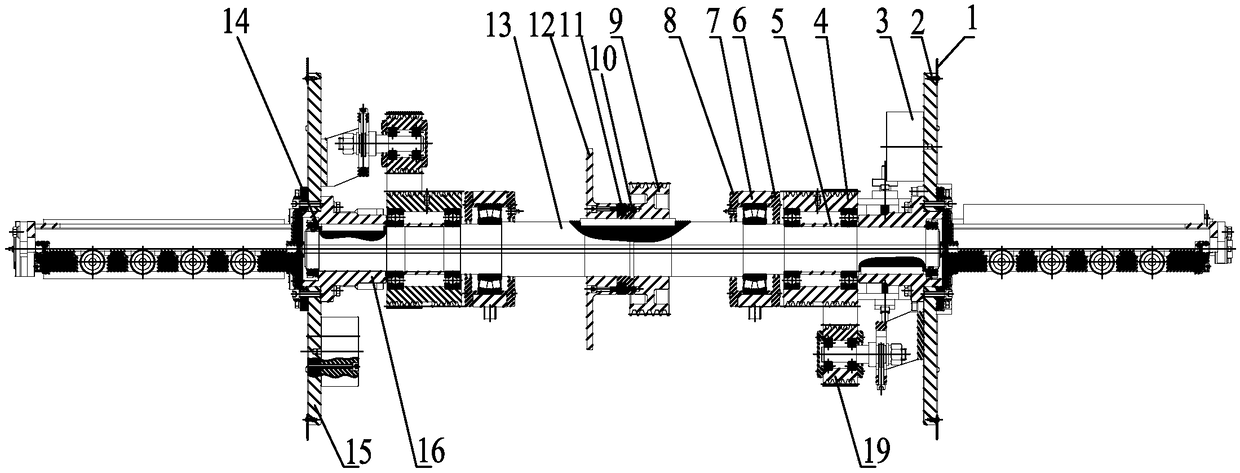

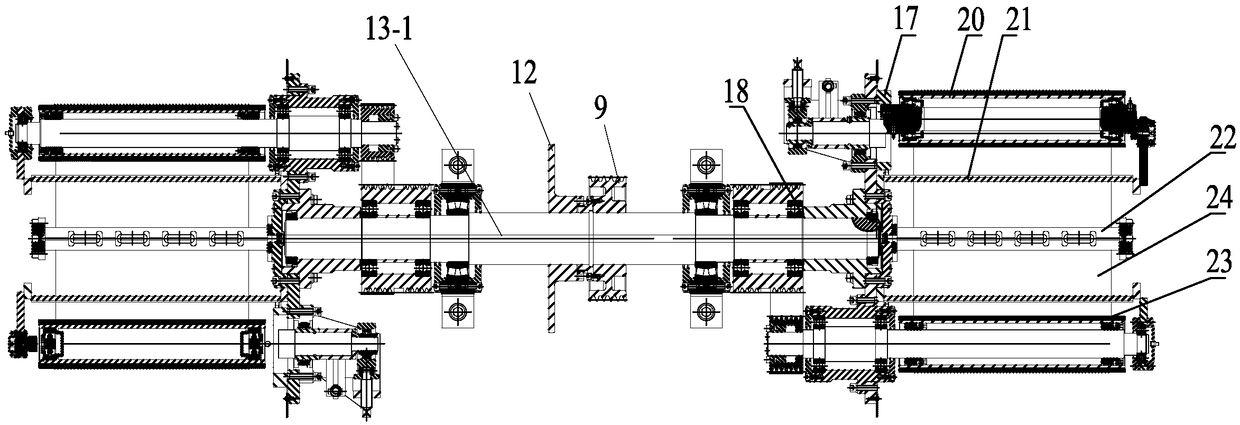

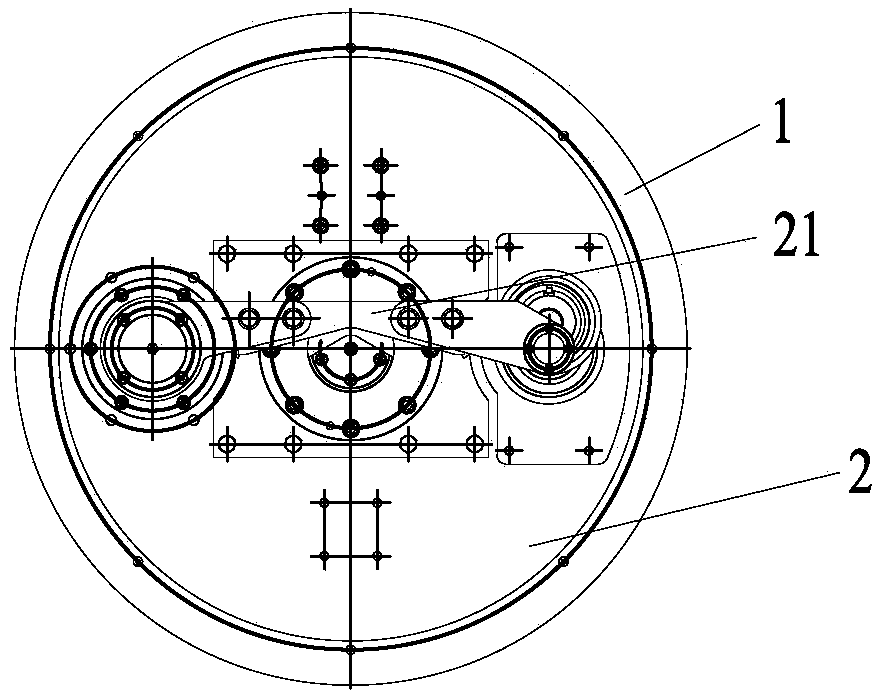

[0026] Figure 1~4 , including dustproof ring 1, disk 2, counterweight 3, double pulley 4, spacer 5, outer end cover 6, bearing housing 7, inner end cover 8, main pulley 9, first adjustment ring 10. Second adjusting ring 11, brake disc 12, main shaft 13, wire hole 13-1, first washer 14, connecting sleeve 16, counterweight plate 17, second washer 18, tensioner assembly 19, passive eccentric shaft Component 20, bracket 21, half shaft assembly 22, drive shaft component 23, abrasive belt 24, etc.

[0027] Such as Figure 1~4 As shown, the present invention is a turntable device of a derusting machine, comprising: a main shaft 13 having an axially penetrating wire hole 13-1 and being rotatably supported by a bearing seat 7;

[0028] The rotating assembly has two groups, which are respectively connected to the axial ends of the main shaft 13 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com