Surface treatment method of single crystal silicon carbide substrate and single crystal silicon carbide substrate

A surface treatment and single crystal technology, applied in chemical instruments and methods, after treatment, single crystal growth, etc., can solve problems such as crystallization defects of single crystal SiC substrates

Active Publication Date: 2017-12-05

TOYOTA TSUSHO

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the surface of a single crystal SiC substrate may initially have crystalline defects, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

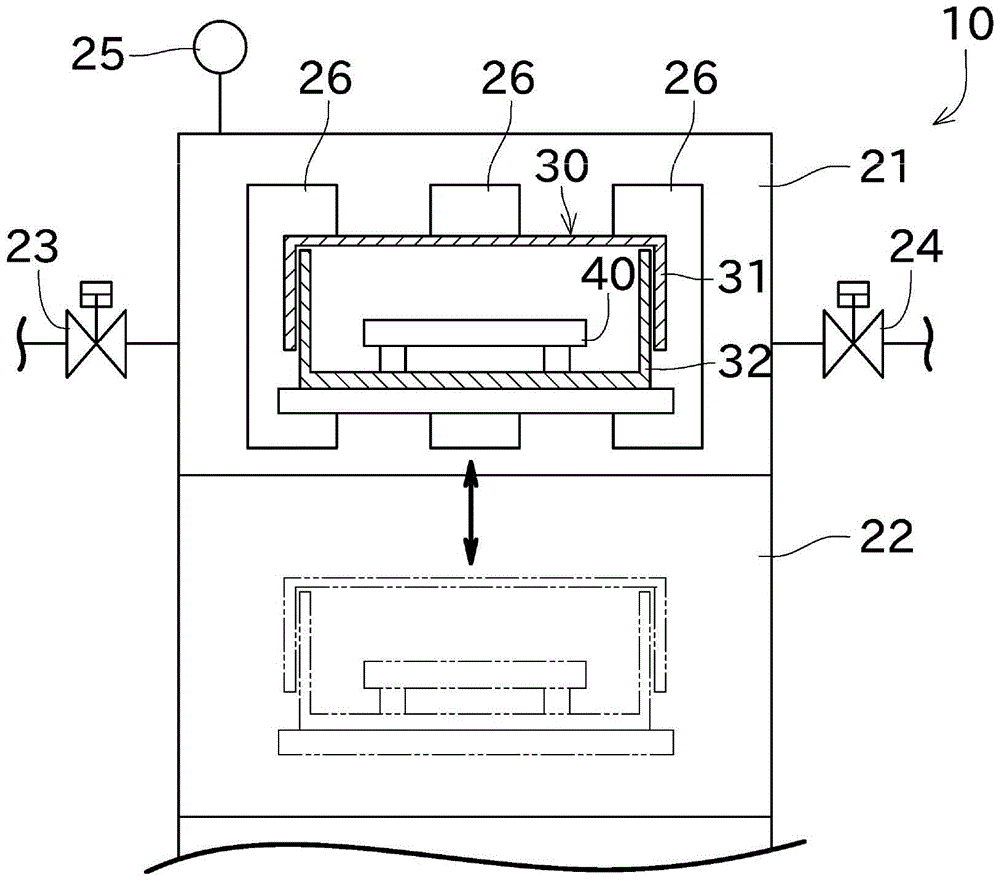

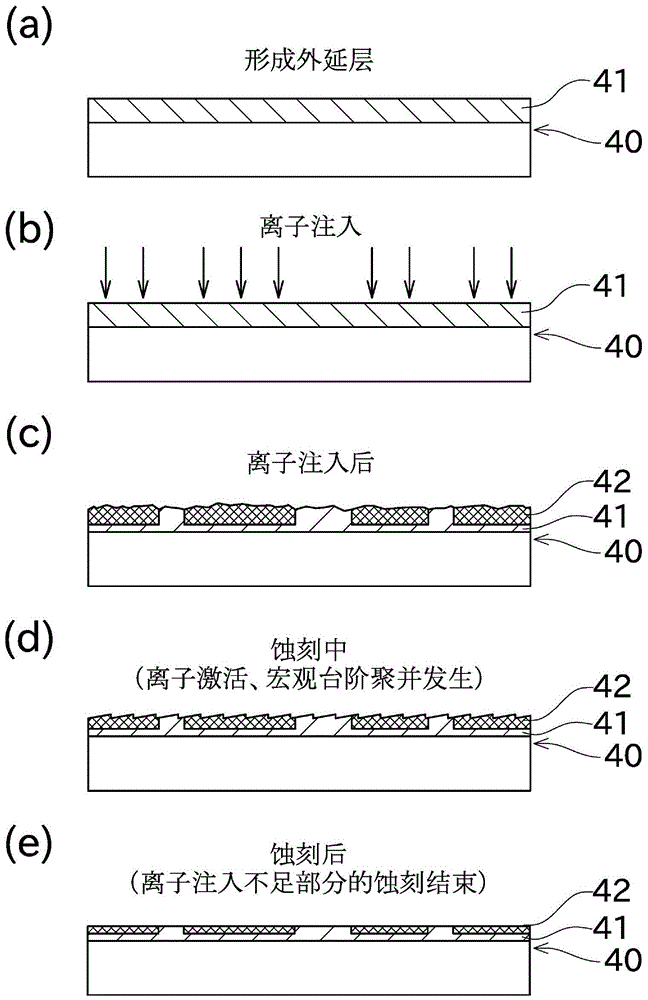

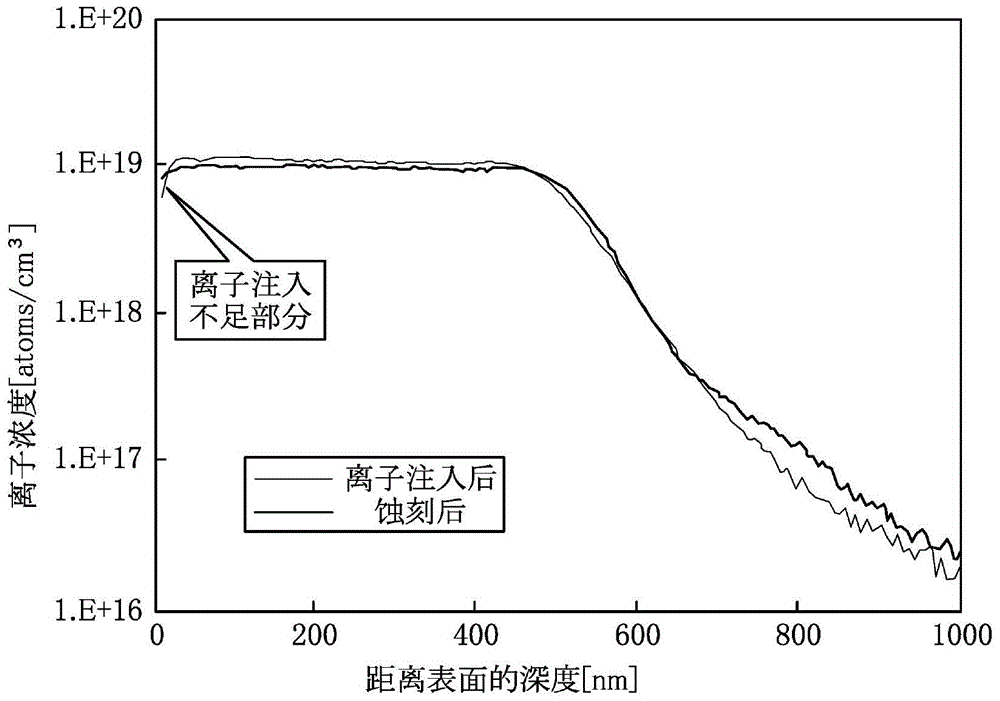

[0095] At high temperature (500°C), 1×10 19 atoms / cm 3 , Under the condition of 500nm away from the substrate surface, for 4H-SiC, 4°-off (0001), (□10mm / 4”), epitaxial layer n-typel×10 16 / cm 3 Al + Multilevel implantation of ions. The ion-implanted single crystal SiC substrate was placed in the above-mentioned covered crucible with a diameter of 20 mm, and was etched for 5 minutes at 1600° C. in an Ar 1.3 kPa gas atmosphere.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Login to View More

Abstract

The present invention provides a surface treatment method capable of controlling the etching rate of a single crystal SiC substrate with high precision and accurately grasping the amount of etching. In this surface treatment method, a single crystal SiC substrate is etched by heat treatment under Si vapor pressure. And, when performing this etching, the etching rate is controlled by adjusting the pressure of the inert gas in the gas atmosphere around the single crystal SiC substrate. Thereby, the amount of etching can be grasped accurately.

Description

technical field [0001] The invention mainly relates to a method for controlling the etching rate on the surface of a single crystal SiC substrate with high precision. Background technique [0002] Since SiC (silicon carbide) has excellent heat resistance and mechanical strength compared with Si (silicon) and the like, it has attracted attention as a new semiconductor material. However, the surface of the single crystal SiC substrate may initially have crystal defects and the like. [0003] Patent Document 1 discloses a surface flattening method for flattening (repairing) the surface of this single crystal SiC substrate. In this surface flattening method, a carbide layer and a sacrificial growth layer are formed on a single crystal SiC substrate, and the sacrificial growth layer is etched to flatten the surface. Thereby, a high-quality seed crystal substrate for epitaxial growth can be produced. Furthermore, Patent Document 1 discloses etching under high vacuum. [0004] ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C30B29/36C30B33/12

CPCC30B29/36C30B33/12C30B31/22H01L21/3065H01L29/1608C30B33/02C30B33/08H01L21/0445

Inventor 鸟见聪矢吹纪人野上晓

Owner TOYOTA TSUSHO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com