Chainless double fly linkage lever direct drive bicycle

A chainless, direct-drive technology that is applied to vehicle components, rider drive, transportation, and packaging. It can solve problems such as complex device structure, low drive efficiency, and impact on riding effects, and achieve labor-saving and energy-saving riding. Manufacturing cost, effect of improving cycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

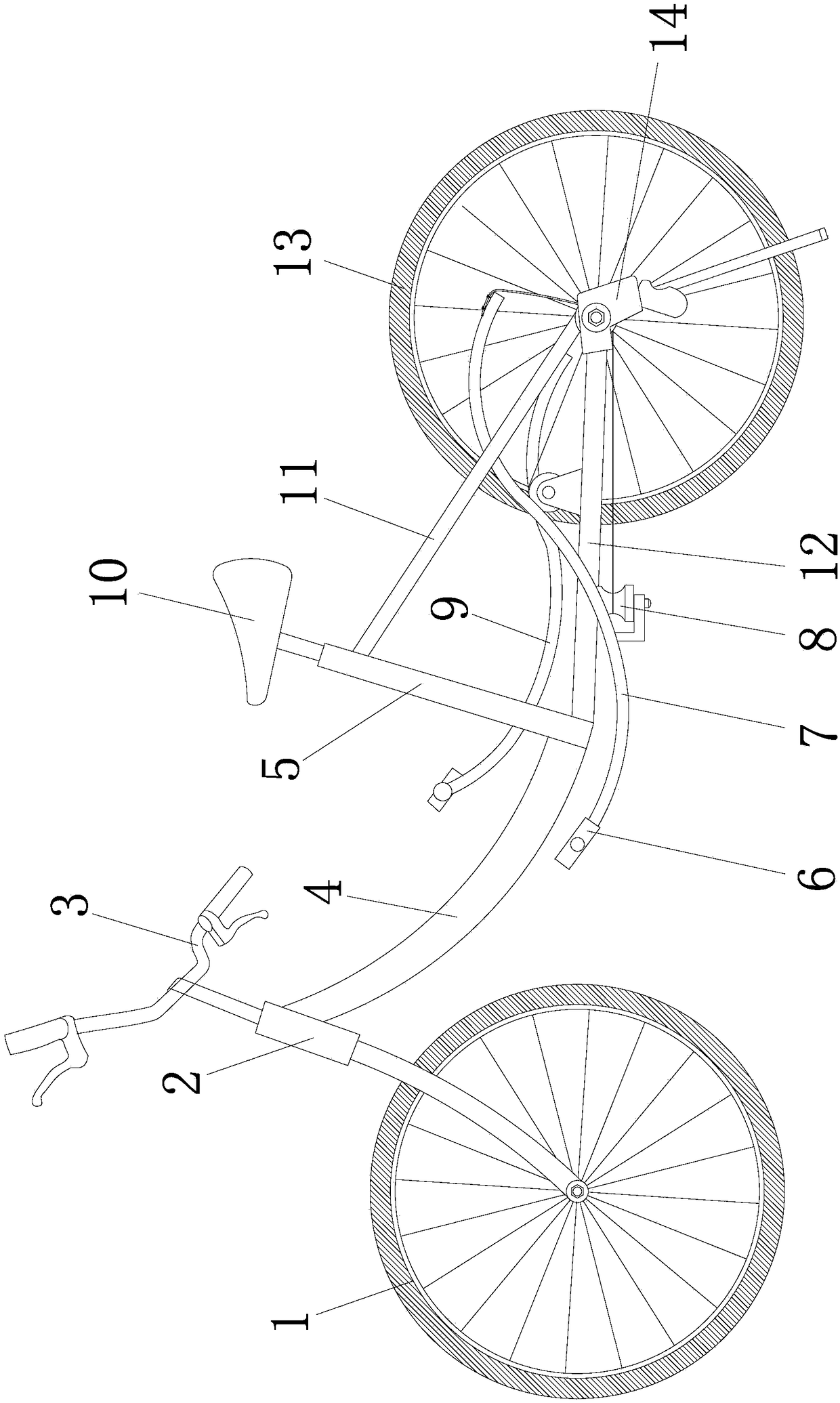

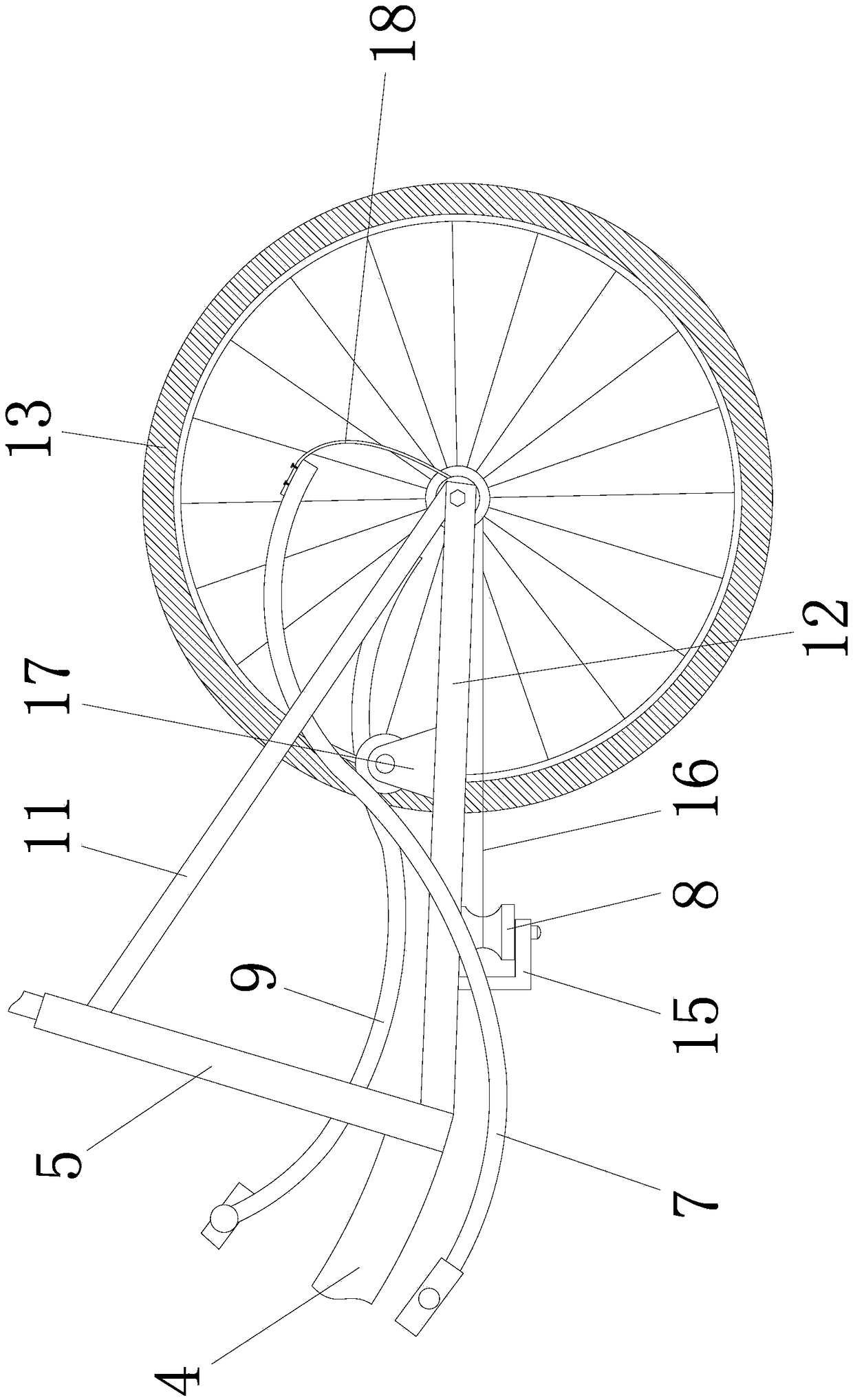

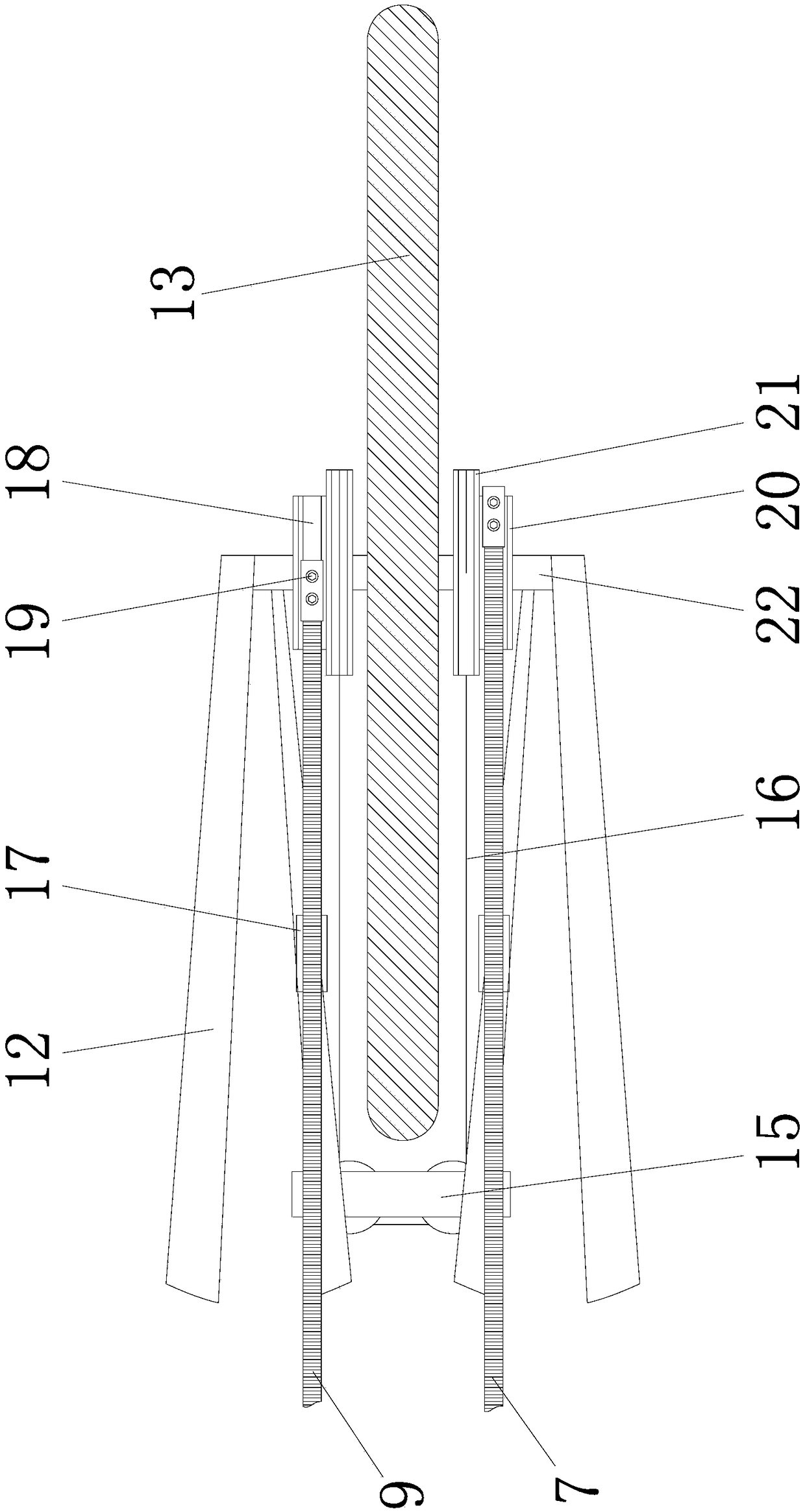

[0023] Such as Figure 1-4 Shown, a kind of chainless double-fly linkage lever direct-drive type bicycle comprises front wheel 1, front vehicle frame 2, rear wheel 13, handle 3, seat 10, seat support 5, connecting rod frame 4, support foot 14, and setting Back vehicle frame 11 and underframe 12 on rear wheel 13 both sides; Underframe 12 top is provided with bearing wheel 17, is connected with left crank 7 and right crank 9 on bearing wheel 17, the front end of left crank 7 and right crank 9 Pedal 6 is provided, and the rear end of left crank 7 and right crank 9 is connected with belt 18, and both sides of rear axle 22 on the rear wheel 13 are provided with sheaves, and sheaves are provided with inner groove 21 and outer groove 20 , the inside of the grooved wheel is provided with a flywheel, the center of the flywheel is connected to the center of the rear wheel to form an integral body, the center hole of the flywheel and the rear wheel is connected to the rear axle 22 in rot...

Embodiment 2

[0026] Such as Figure 5 As shown, a chainless double-fly linkage lever direct-drive bicycle, the pulley 8 is canceled in the rebound mode, the steel wire rope 16 is combined with the spring 23 to form a steel wire spring rope, one end of the steel wire spring rope is connected with the support 15, and the other end of the steel wire spring rope One end wraps around the inner groove 21 and is clamped and fixed with the inner groove 21 .

Embodiment 3

[0028] Such as Figure 6 Shown, a kind of chainless double-fly linkage lever direct-drive type bicycle cancels support 15, pulley 8, steel wire rope 16 and inner groove 21 in the rebound mode, and torsion spring 24 is set on the rear axle, and one end of torsion spring 24 and outer groove 20 inner sides are connected, and the other end of the torsion spring 24 is connected and fixed with the underframe 12, and the sheave is rotated and reset by the torsion of the torsion spring 24.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com