Roller unstacking deviceand method

A technology of rollers and rollers, which is used in the destacking of objects, conveyor control devices, transportation and packaging, etc., can solve the problems of limited size of goods, deformation of goods, and low efficiency, and reduce the impact of subsequent operations. , The effect of reducing the deformation of goods and improving the efficiency of depalletizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

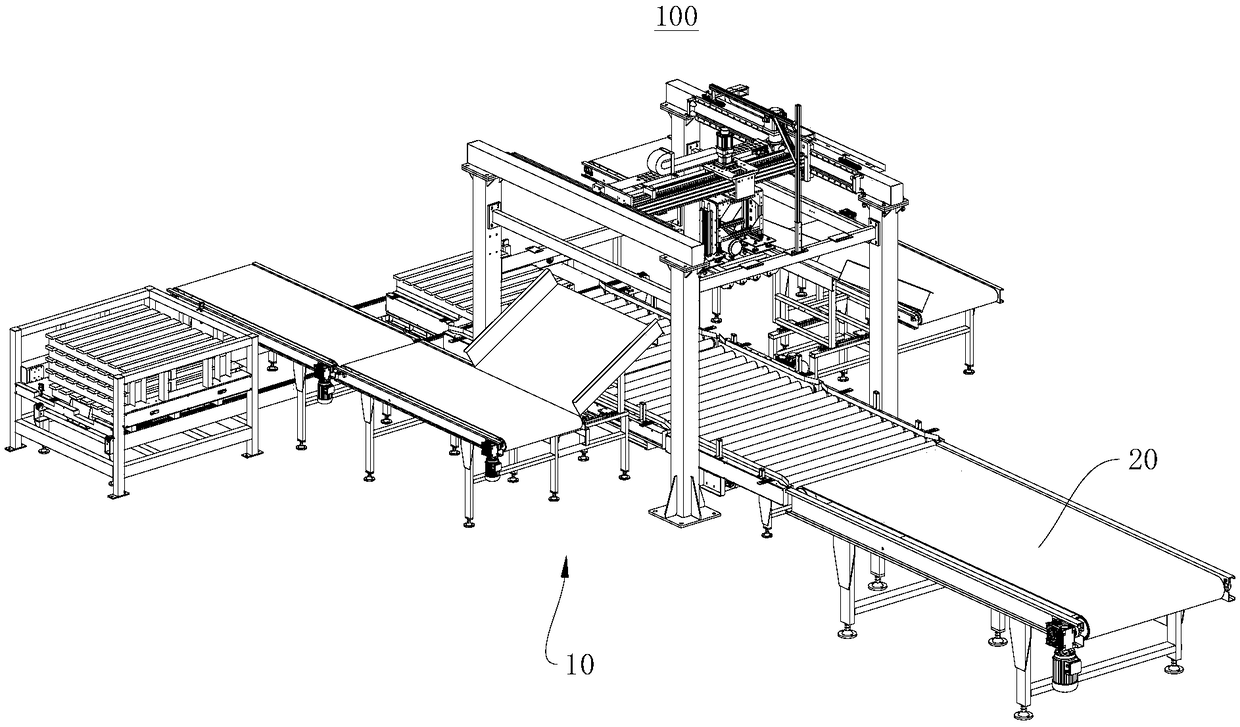

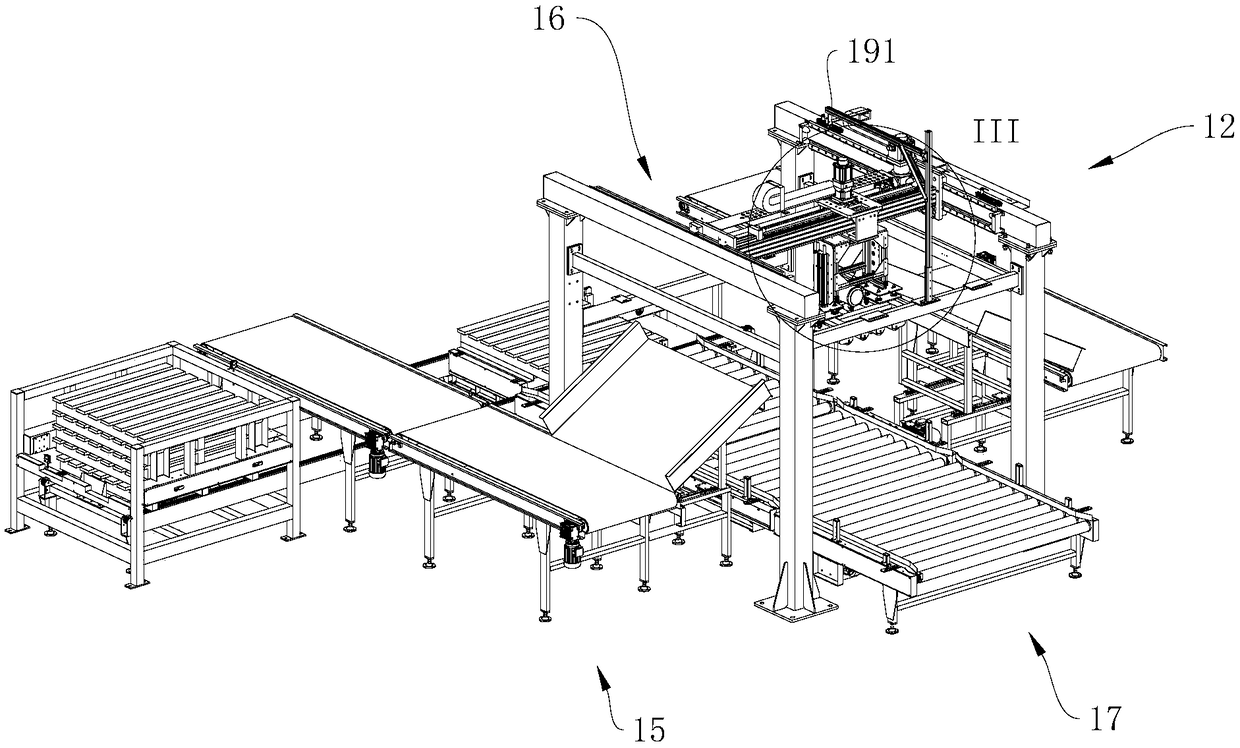

[0043] see figure 1 , figure 1 It is a structural schematic diagram of applying the roller unstacking device 10 to the conveying system 100 according to the first embodiment of the present invention.

[0044] The embodiment of the present invention provides a roller destacking device 10 , which has high destacking efficiency, and is less likely to cause deformation of goods and less prone to stacking of goods during the destacking process. The roller unstacking device 10 can be applied to a conveying system 100 , a production line, an automated warehouse, a logistics system or an automated factory, etc. Of course, the roller unstacking device 10 can also be used independently.

[0045] Taking the application of the roller depalletizing device 10 to the conveying system 100 as an example, the conveying system 100 includes the roller depalletizing device 10, which participates in the depalletizing operation of the stack through the roller depalletizing device 10, and the convey...

no. 2 example

[0091] see Figure 9 , Figure 9 It is a schematic flowchart of the roller unstacking method provided by the second embodiment of the present invention.

[0092] The roller unstacking method is applied to the roller unstacking device 10 provided in the first embodiment, and the roller unstacking method includes:

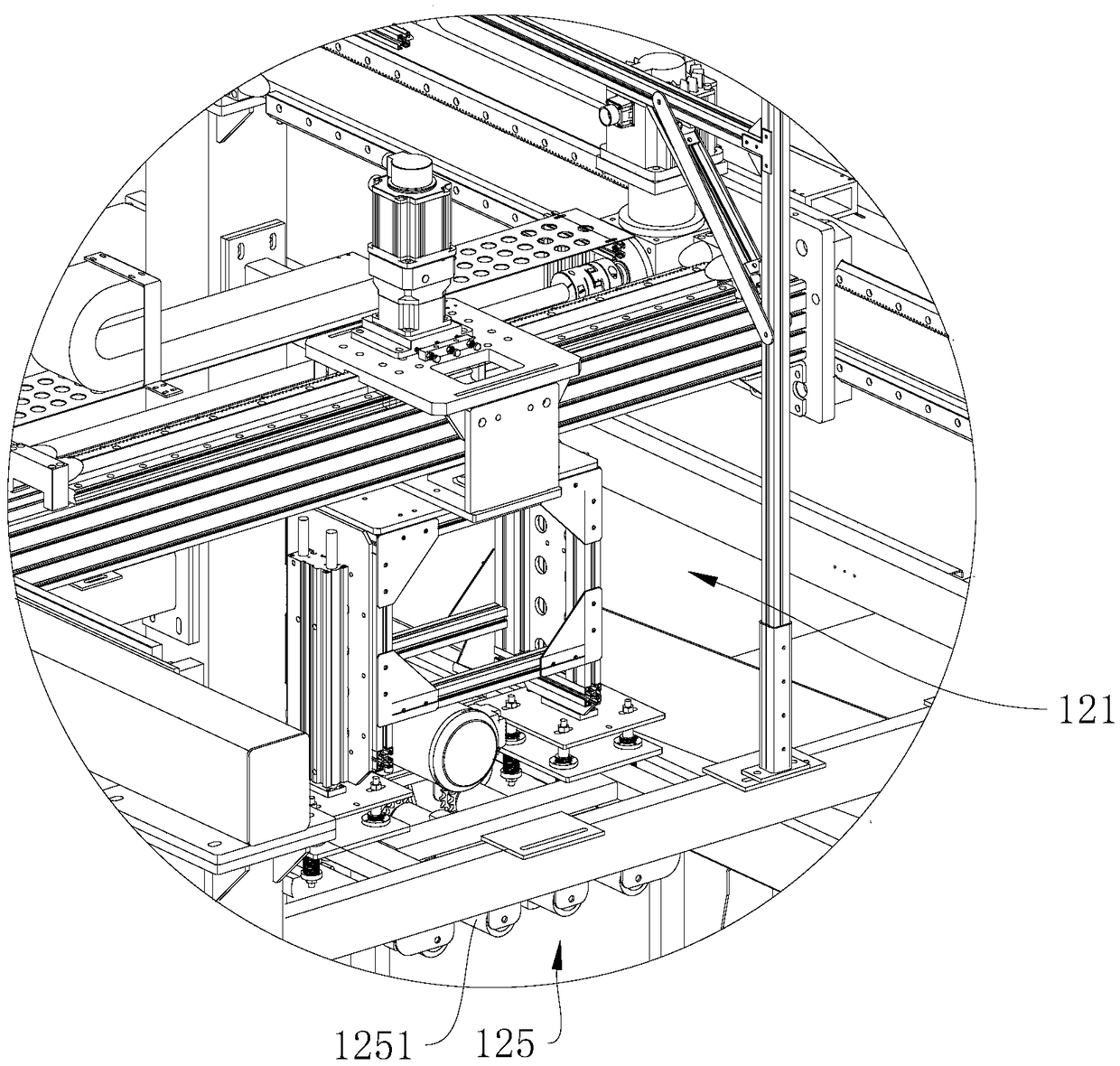

[0093] Step S101: Drive the dismantling roller 1251 to move towards the top layer of goods by the dismantling moving mechanism 121, and make the dismantling roller 1251 press and hold the top layer of goods.

[0094] Step S102: Rotate the split roller 1251 to drive the top layer of goods to move towards the material receiving table 151 located at the bottom edge of the top layer of goods.

[0095] Further, the roller destacking method may also include:

[0096] Step S103 : receiving the goods driven by the dismantling roller 1251 through the tilted material receiving platform 151 , and making the goods slide outward along the material receiving platform 151 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com