A method for preparing cementitious material using Chaerhan salt lake solution, slag and silica fume

A technology of cementitious material and salt solution, applied in cement production and other directions, can solve the problems of easy cracking, limited production and application of cementitious materials, too fast setting time, etc., and achieves good mechanical properties and rheology, remarkable economic and Practicality and the effect of promoting economic circular development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

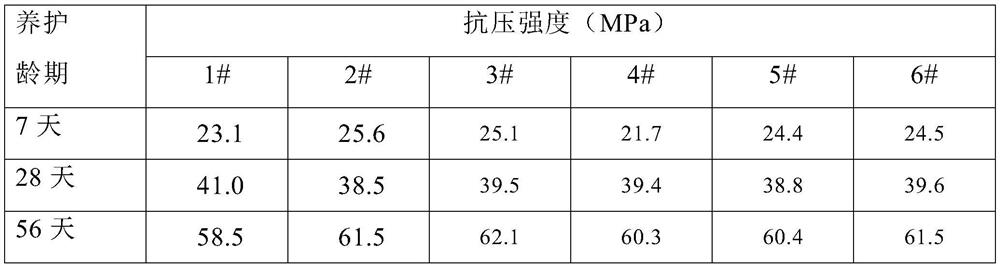

Examples

Embodiment Construction

[0025] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0026] A kind of method using Chaerhan salt lake solution and slag, silica fume to prepare cementitious material, comprises the steps:

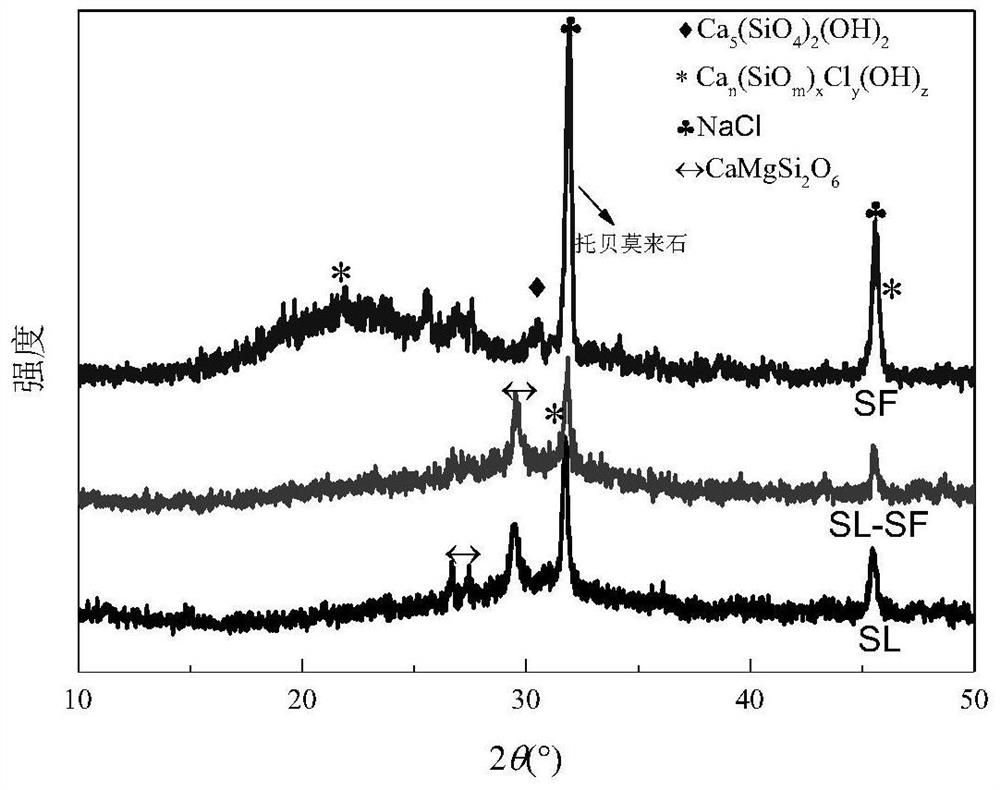

[0027] 1. Take salt lake brine solution: simulate the type and content of ions in Chaerhan Salt Lake and configure the salt solution with the same ion concentration. The concentration of the salt solution is: KCl: 11g / L, NaCl: 90g / L, CaCl 2 : 12g / L, MgCl 2 : 60g / L, MgSO 4 : 30g / L. After the solution is prepared, it is left to stand in a sealed environment for a day and night, and then it is ready for use.

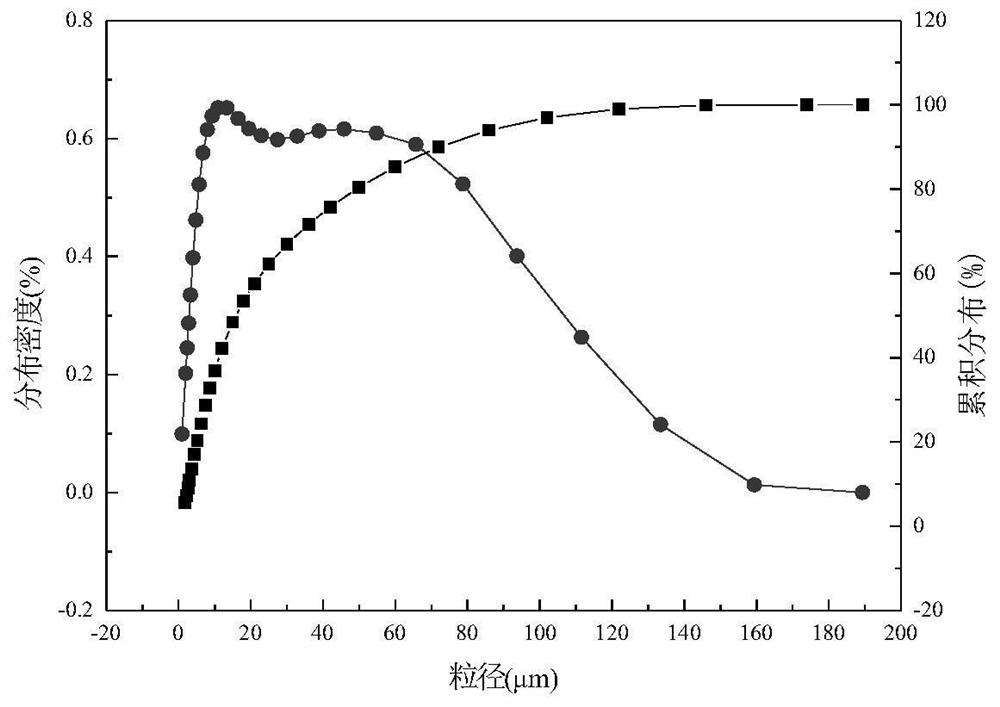

[0028] 2. Crushing and grinding the granulated blast furnace slag until the specific surface area is greater than 350m 2 / kg to obtain granulated blast furnace slag powder, the gelling activity index reaches S95 level, and the silica fume is ground until the specific surface area is greater than 20,000m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com