Tunnel lining thickness insufficiency fast reinforcement method based on clad steel plate or steel strip highway

A technology of composite steel plates and highway tunnels, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of affecting the force, encroaching on the boundary of the tunnel, destroying the integrity of the lining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

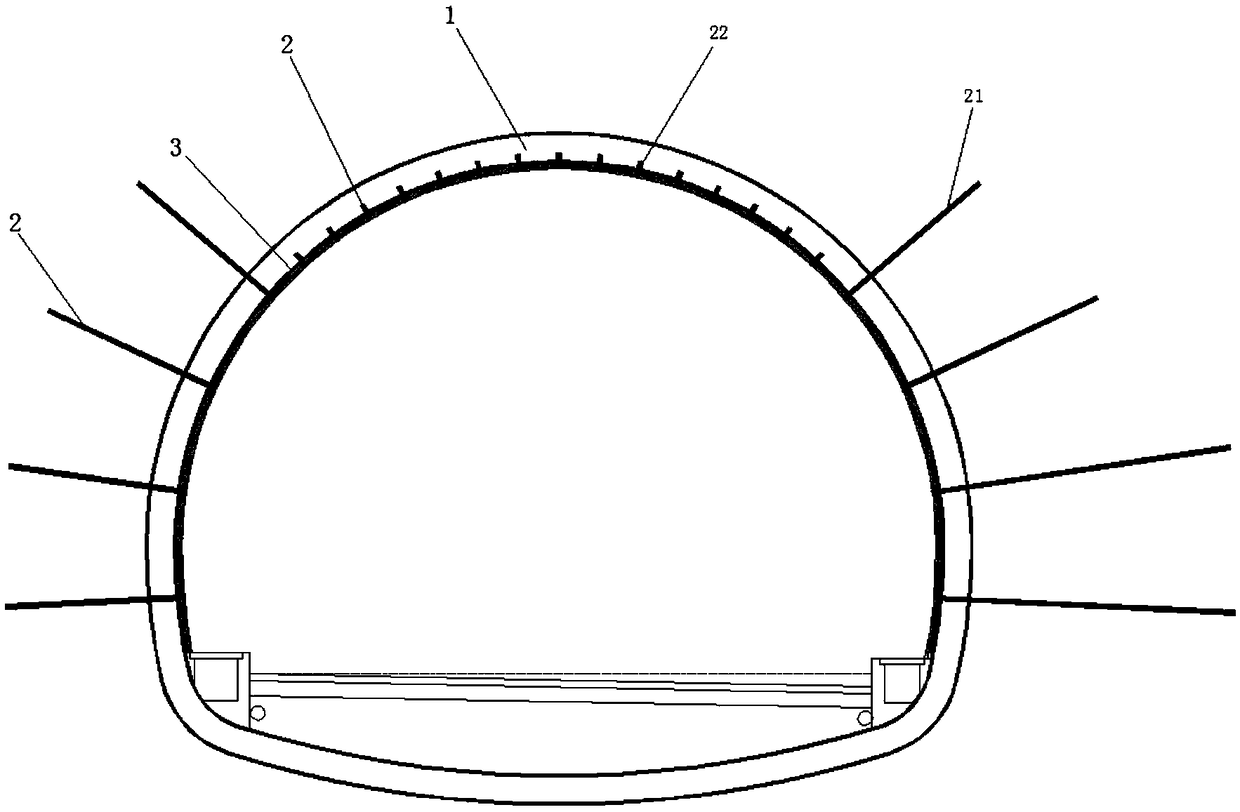

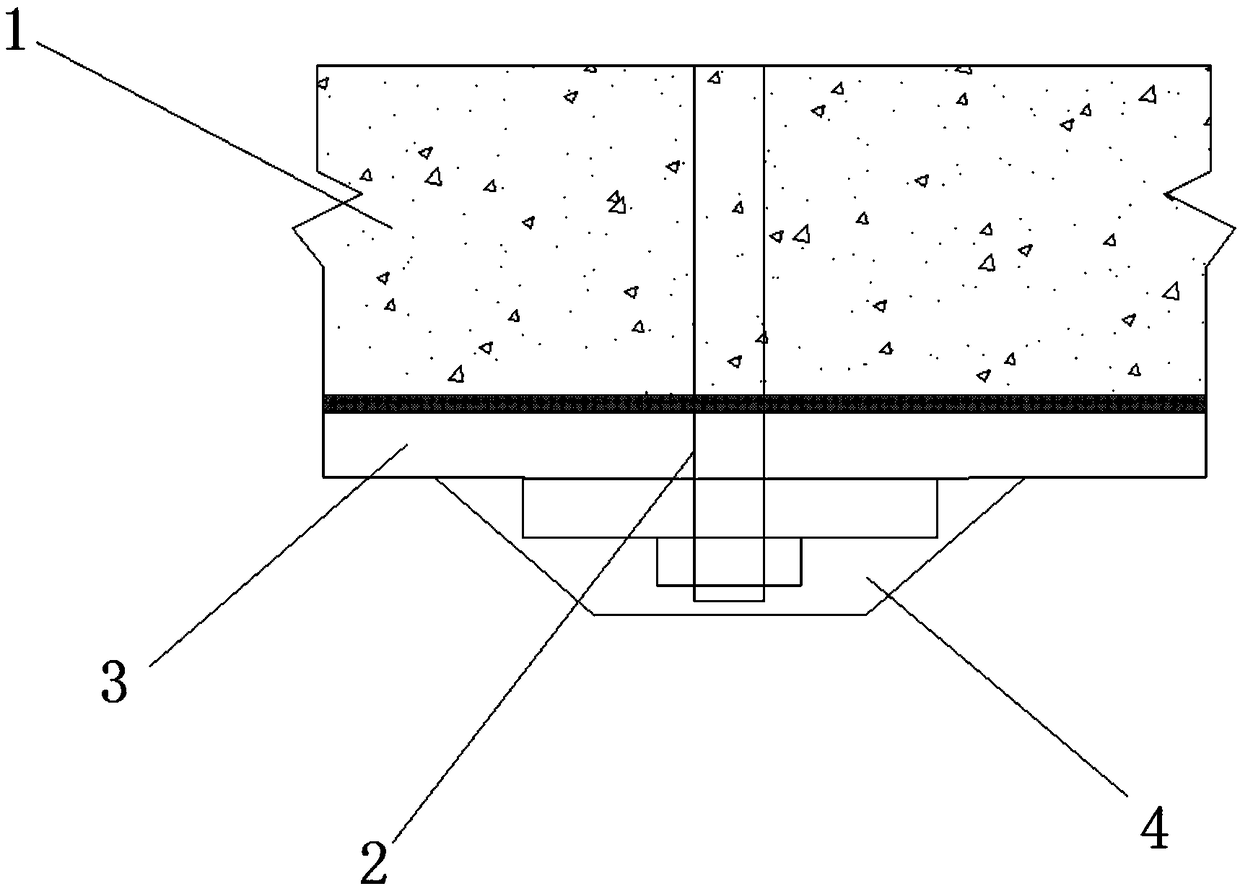

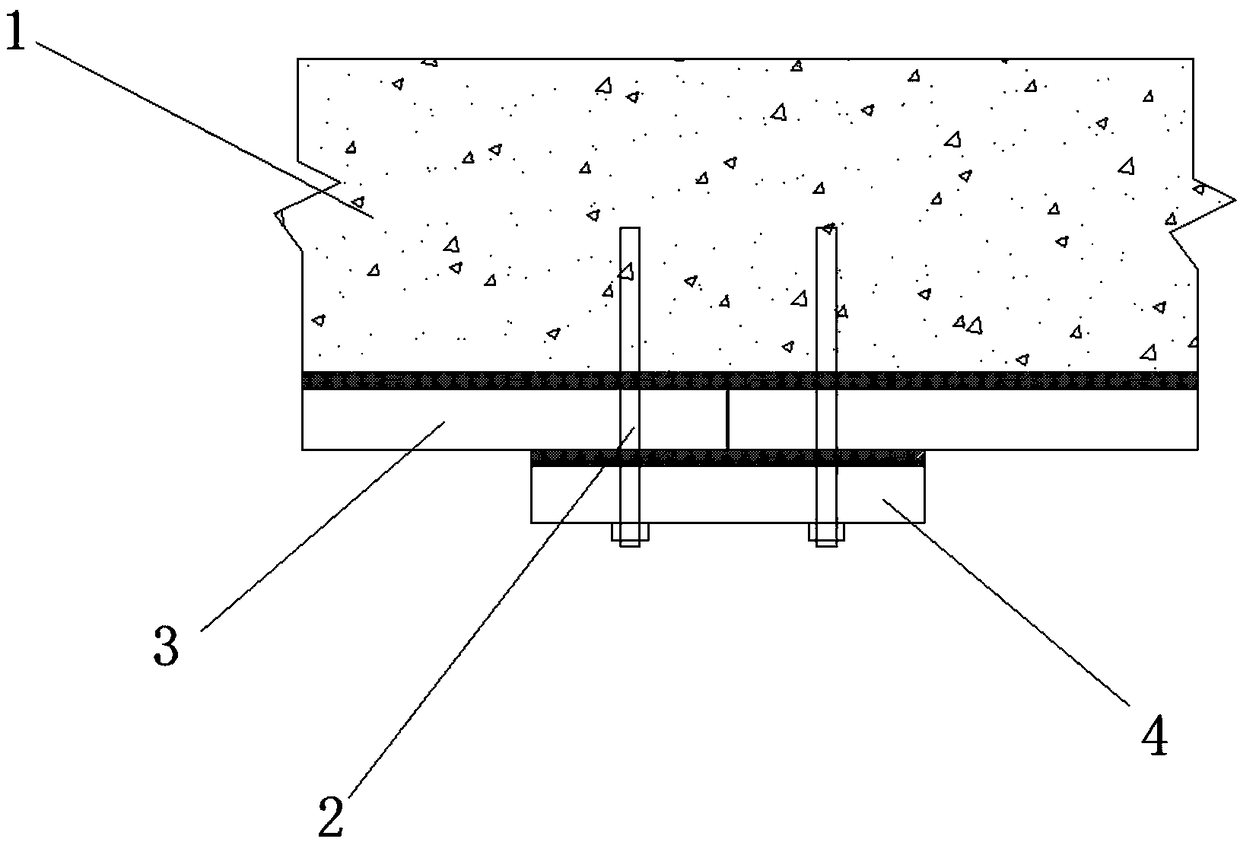

[0026] A rapid reinforcement method based on composite steel plate or steel belt road tunnel lining with insufficient thickness, such as Figure 1-Figure 6 shown, including the following steps:

[0027] a. Use the ground radar with the corresponding antenna. The model of the ground radar is TSP203 or TSP203A; detect the area where the thickness of the second lining 1 is insufficient; process the position and range where the thickness of the second lining 1 is detected to be insufficient, and process the range of the second lining 1 Expand no less than 100-200cm than the actual area to be treated;

[0028] Treatment of lining surface defects within the scope of lining 2 lining 1 should be treated, crack disease adopts crack disease treatment measures, surface defect adopts surface defect treatment measures, and after treatment, it is treated with steel plate bonding;

[0029] b. Grind the lining surface within the scope of the second lining 1 to a depth of 2-3mm. The new surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com