Condensate hammer suppression device with spoiler raised structure

A suppression device and condensate water technology, which is applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve problems such as inability to effectively suppress condensate water hammer, achieve weakening of water hammer strength, simple processing methods, and deceleration effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

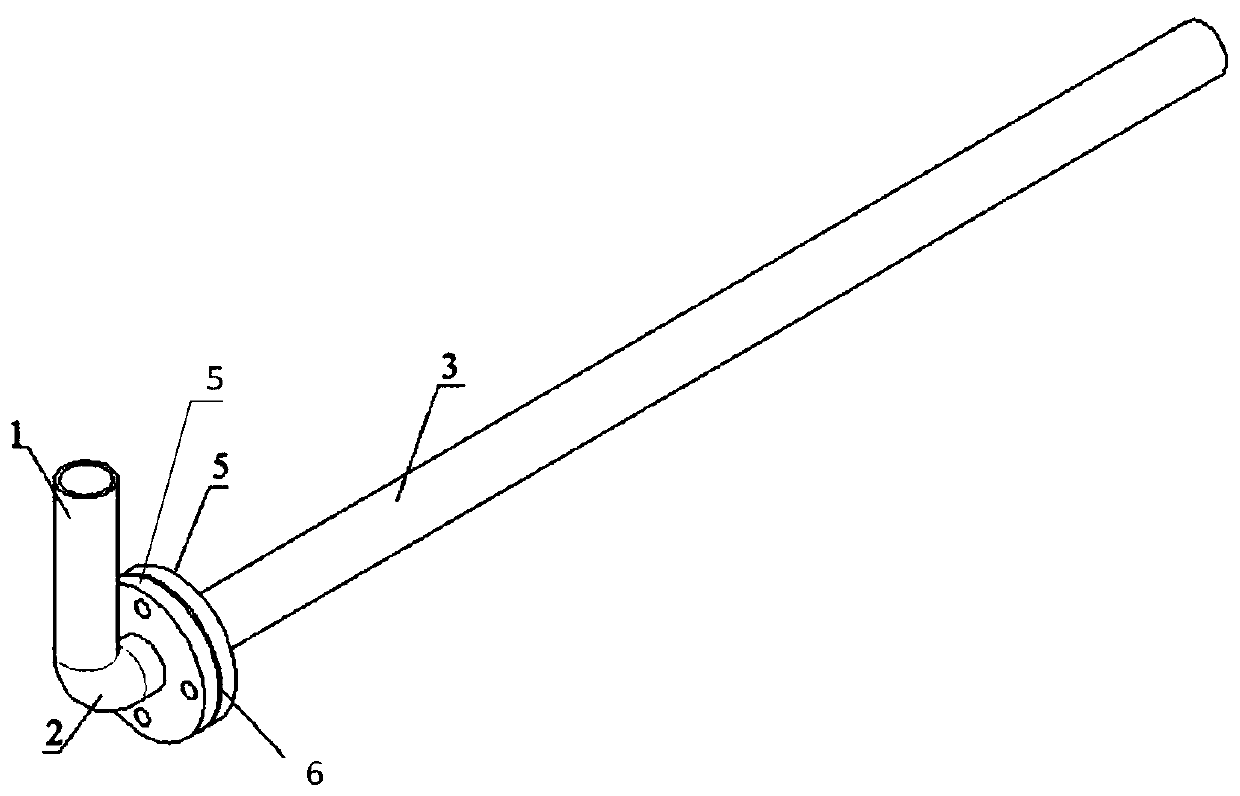

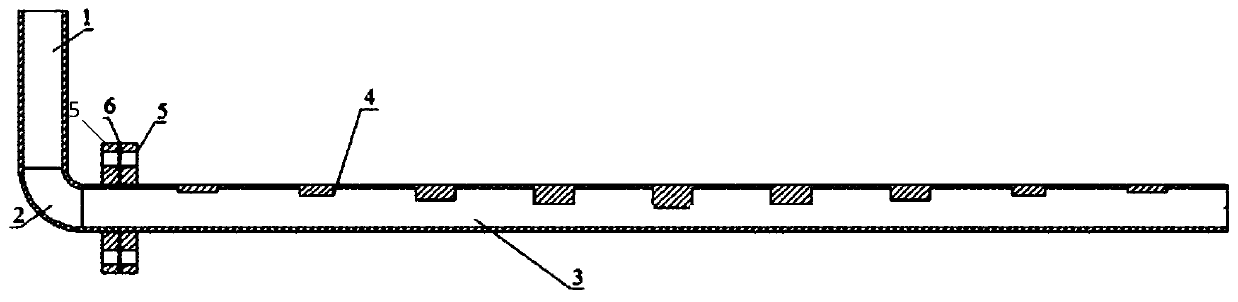

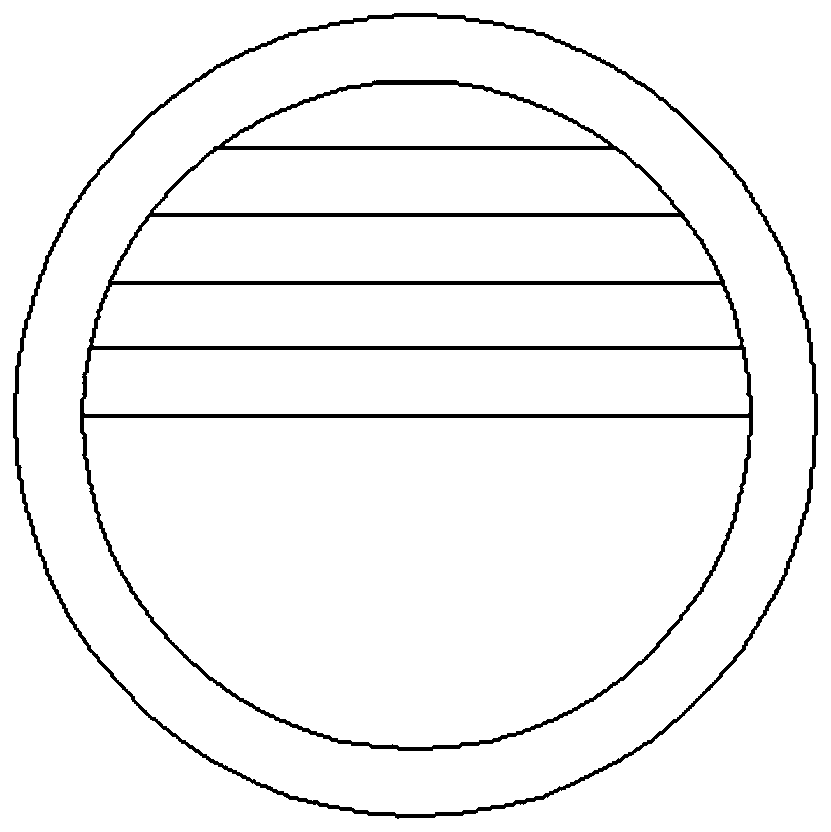

[0019] The embodiment of the present invention provides a condensate hammer suppression device with a turbulence protrusion structure. The condensate hammer suppression device is installed behind the steam inlet pipe, and includes a vertical pipe 1, an elbow 2, a horizontal straight pipe 3, a vertical The pipe 1 and the elbow 2 are connected by welding, and the elbow 2 and the horizontal straight pipe 3 are connected by a flange, and the inner wall of the horizontal straight pipe 3 is provided with no less than 5 spoilers at intervals along the length direction of the horizontal straight pipe 3 Among the protrusions 4, the height of the most middle spoiler protrusion 4 is the highest, and the height of each spoiler protrusion 4 decreases successivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com