Biomass combustor

A burner and biomass technology, applied in the combustion method, combustion equipment, combustion of solid fuel, etc., can solve the problems of small combustion area, small firepower, difficulty in ignition, etc., to increase the combustion area, save manufacturing costs, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

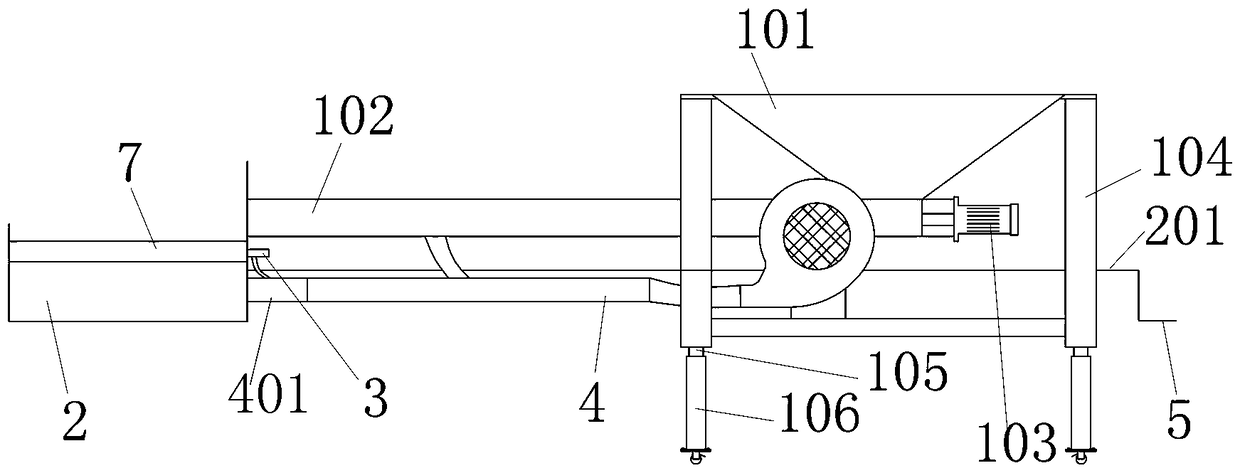

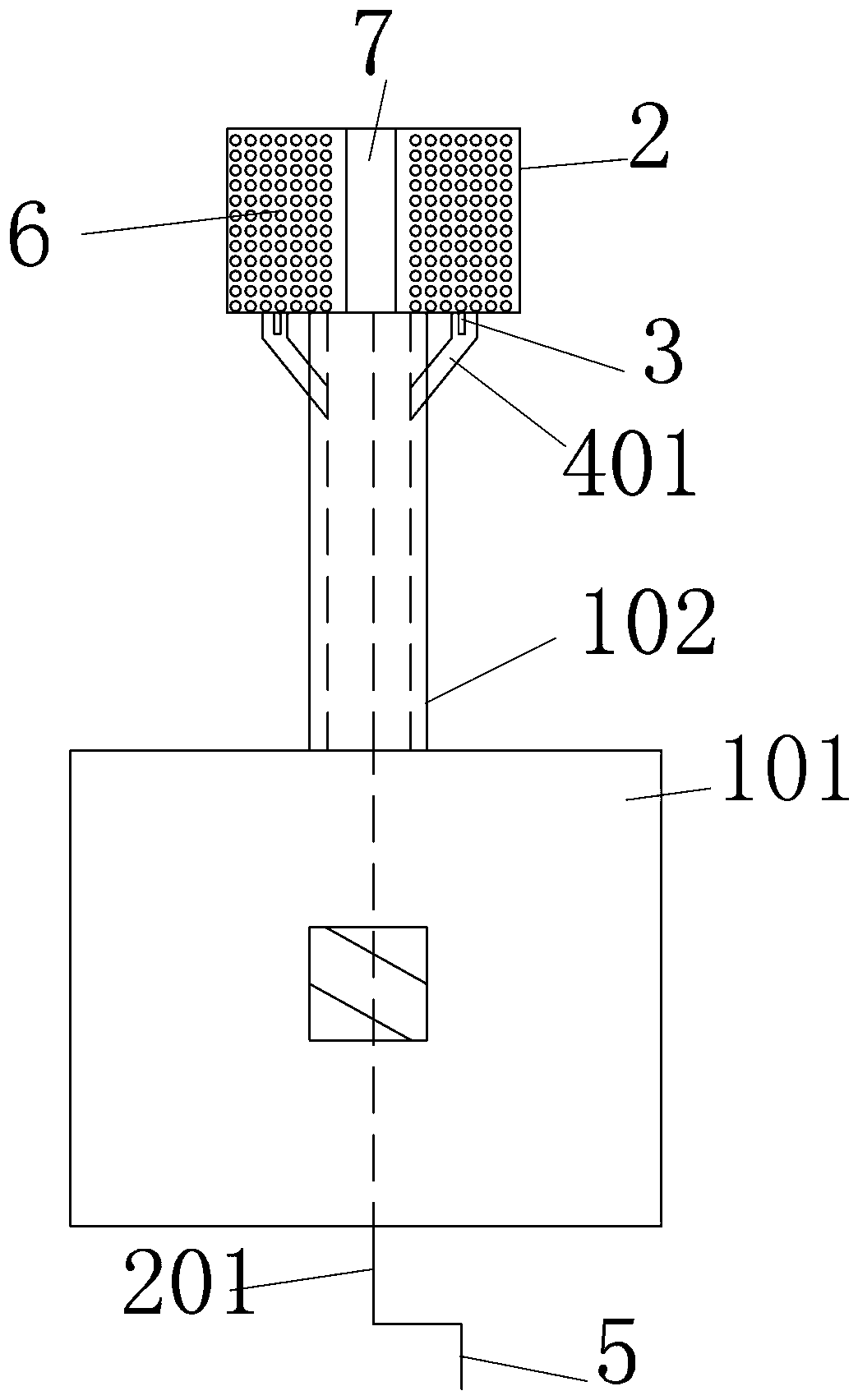

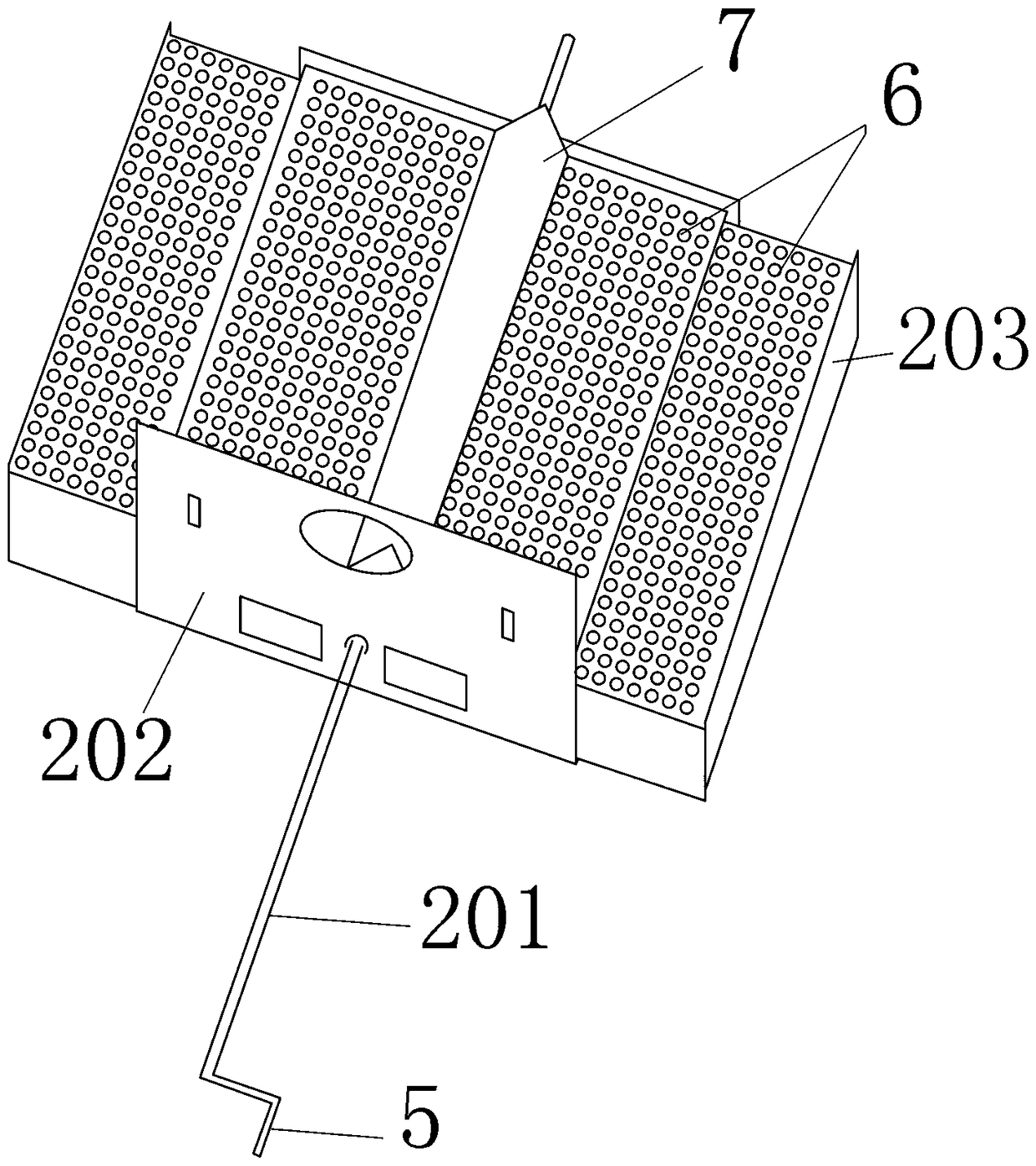

[0042] The preferred solution is as Figure 1 to Figure 4 As shown, a biomass burner includes a feeding device, the feeding device is supported by a bracket 104, the feeding device includes a hopper 101, the bottom of the hopper 101 is provided with a feeding pipe 102, and a feeding device is arranged inside the feeding pipe. Power mechanism is the feeder 103 that is installed in feed pipe 102 afterbody, and feed pipe 102 head is provided with telescopic combustion head 2, and telescopic combustion head 2 is covered with a plurality of pieces of breathable mesh 6, and the retractable combustion head 2 Be provided with a plurality of ignition device sleeve pipes 3 next to the feed inlet, and below the ignition device sleeve pipes 3 are provided with air supply branch pipes 401 of a plurality of air supply pipes 4, the air supply branch pipes 401 communicate with the ignition device sleeve pipes 3, and the air supply pipes 4 It communicates with the feed pipe 102; the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com