A Measuring Method of Numerical Aperture of Optical Lens Based on Computational Imaging

A numerical aperture and optical lens technology, applied in the direction of testing optical performance, etc., can solve the problems of complex operation process, low precision, cumbersome measurement process, etc., and achieve the effect of simple operation process, high measurement accuracy and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

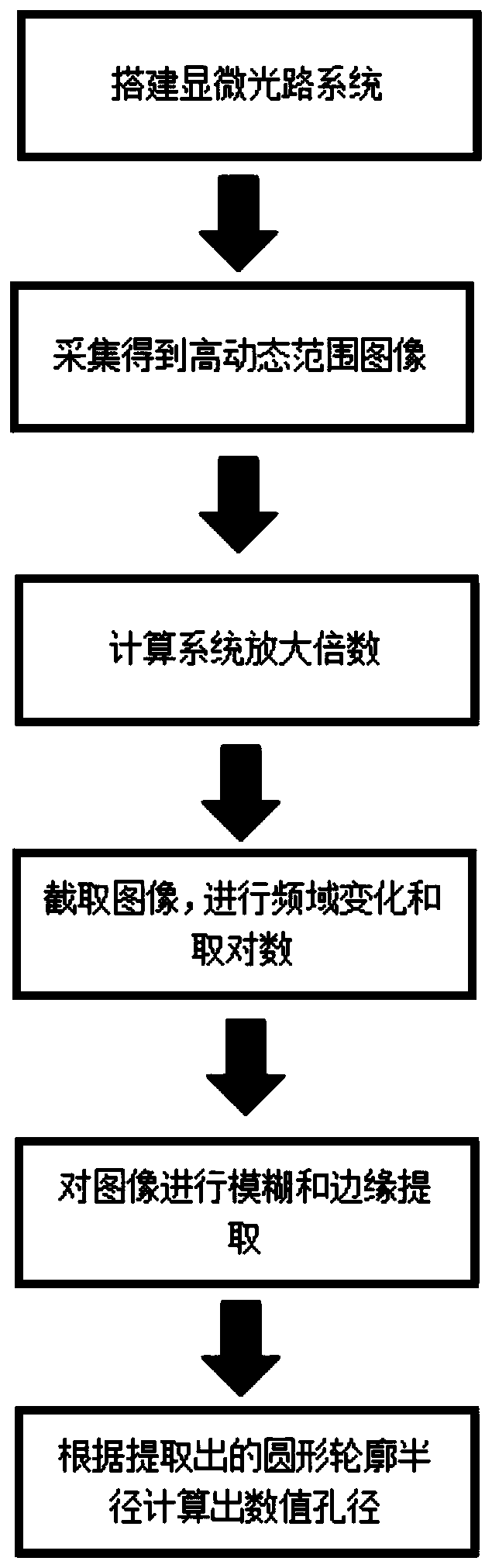

[0019] The specific implementation method of the present invention will be further described below in conjunction with the accompanying drawings, so as to clearly demonstrate the characteristics of the present invention.

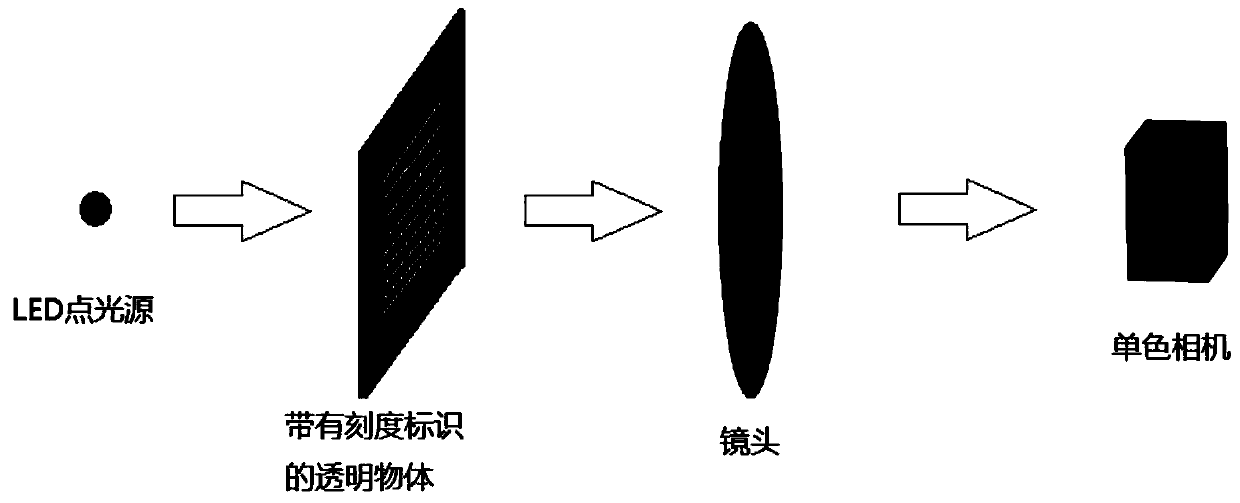

[0020] Such as figure 1 As shown, the optical system for measuring the numerical aperture of the lens includes: an LED point light source, a light-transmitting subject with a length mark, a lens for measuring the numerical aperture, and a monochromatic photosensitive camera (ie, an imaging device). The components are placed in sequence to form a microscopic imaging system.

[0021] Among them, the distance between the LED point light source and the object to be photographed is 60mm-80mm. The longitudinal position of the LED point light source is at the center of the optical axis. The distance between the object to be photographed and the lens to be tested is between one focal length and two focal lengths of the lens to be tested. The distance between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com