Battery test fixture and battery test tooling

A battery testing and testing splint technology, which is applied to measuring devices, measuring device housings, components of electrical measuring instruments, etc., can solve problems such as cumbersome processes, unusable aluminum rows or connecting devices, etc., to reduce material waste, Improve test efficiency and ensure the effect of test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

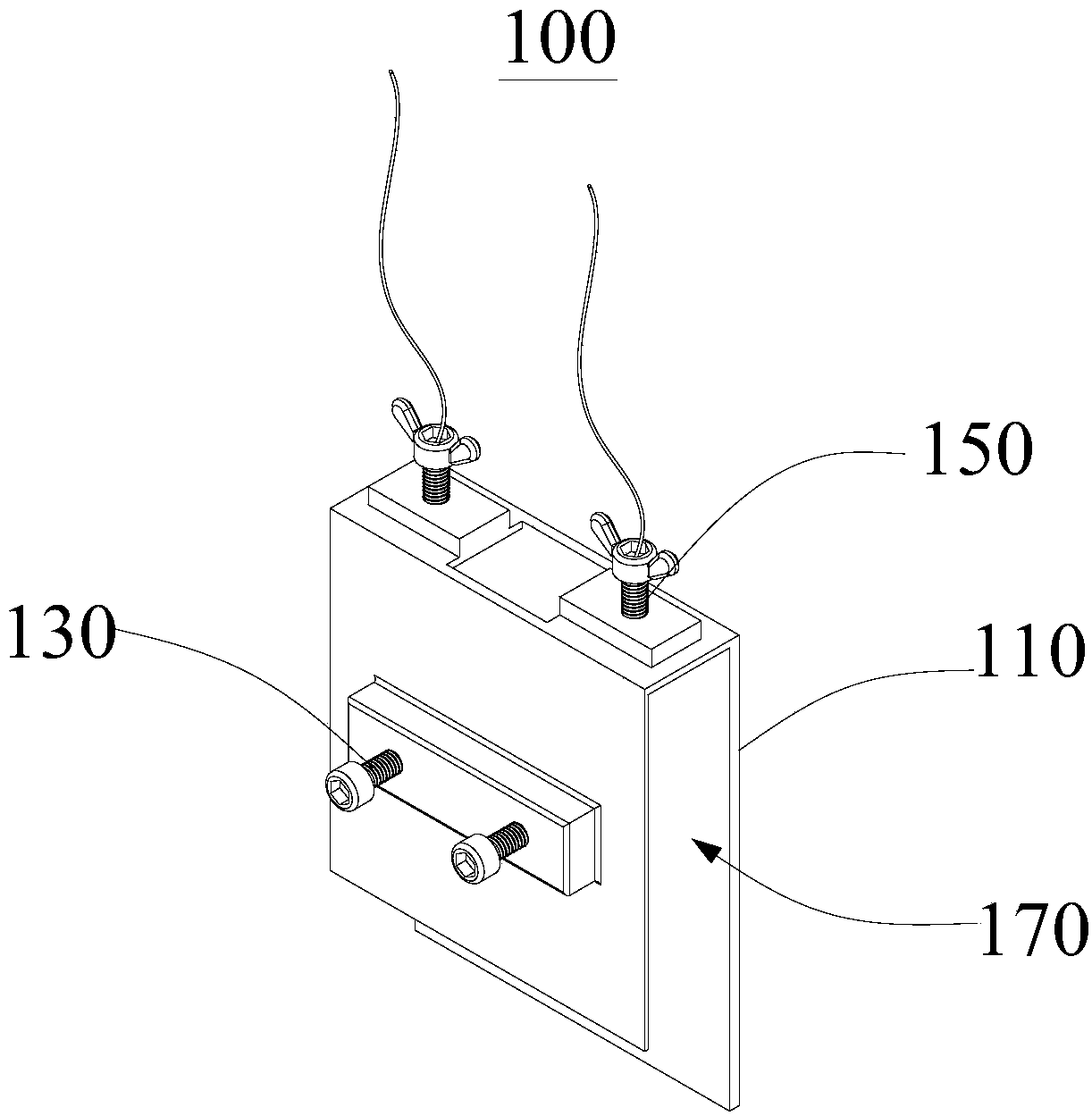

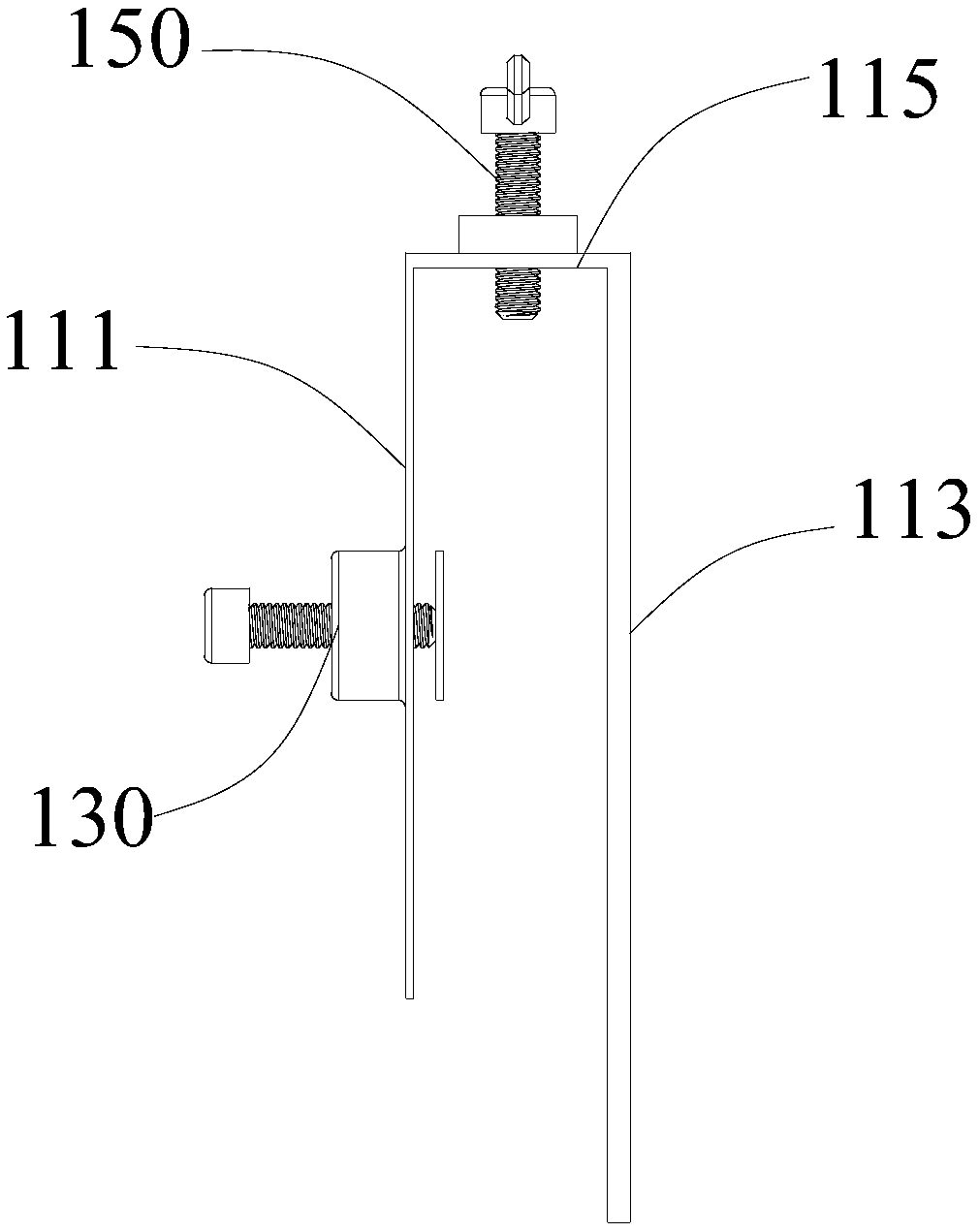

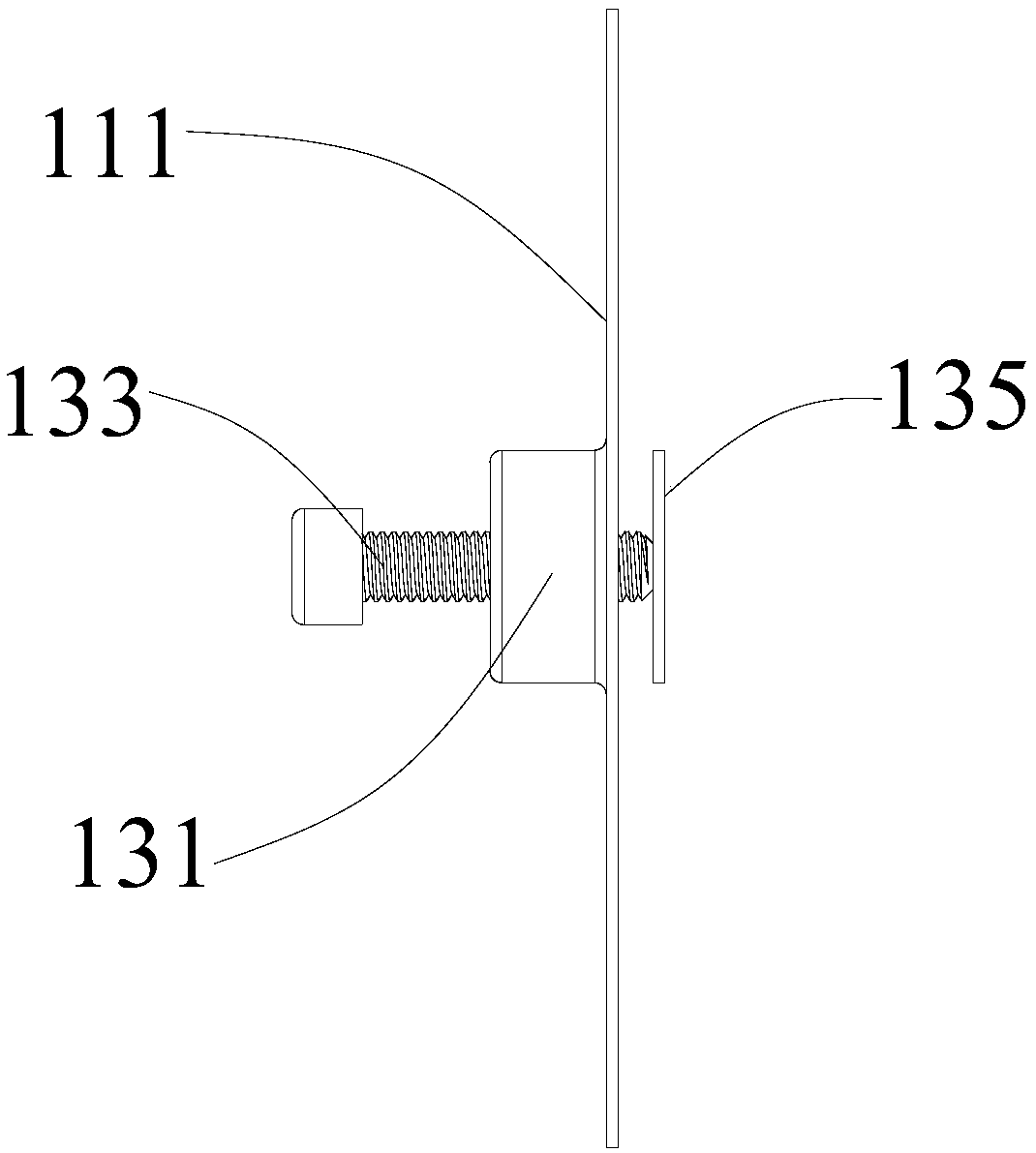

[0034] see figure 1 , this embodiment provides a battery test fixture 100, which is used to clamp and fix the battery to be tested to facilitate subsequent testing. The battery test fixture 100 provided by this embodiment includes a test splint 110, a fastener 130 and a test connector 150. The test clamping plate 110 has a clamping cavity 170 for accommodating the battery to be tested. The fastener 130 is arranged on the testing clamping plate 110 and extends into the clamping cavity 170 for abutting against the battery to be tested. The connecting piece 150 is disposed at the end of the test clamping plate 110 and extends into the clamping cavity 170 for being pressed against the battery to be tested and electrically connected to the battery to be tested.

[0035] It should be noted that, in this embodiment, the casing of the battery to be tested is in the shape of a rectangle, and the shape of the clamping cavity 170 is matched with the battery to be tested, which is conveni...

no. 2 example

[0052] This embodiment provides a battery test tool, including a battery to be tested and a battery test fixture 100, wherein the basic structure, principle and technical effects of the battery test fixture 100 are the same as those of the first embodiment. For brief description, this embodiment For parts not mentioned, reference may be made to the corresponding content in the first embodiment.

[0053] The battery test fixture 100 includes a test clamp plate 110 , a fastener 130 and a test connector 150 , the test clamp plate 110 has a clamping cavity 170 for accommodating a battery to be tested, and the fastener 130 is arranged on the test clamp plate 110 and extends into it The clamping cavity 170 is used to abut against the battery to be tested, and the test connector 150 is disposed at the end of the test clamping plate 110 and extends into the clamping cavity 170 to be used to abut against the battery to be tested and connect with the battery to be tested. The battery is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com